Wafer tools typically need deionized water and other chemicals in the masking process that requires tight control of small valves.

![]()

Since these control valves are too small to accommodate a field mounted I/P or positioner, the highly accurate and repeatable two-wire loop-powered IPT2 DIN mount Current-to-Pressure Transmitter is a perfect solution. The IPT2 can be rack mounted for high-density installations in 5, 10, or 15 position racks that simplify air supply, filtering and regulation due to its backplane header design. The IPT2 includes a pneumatic closed-loop feedback circuit for optimum control, has front mounted test leads to monitor the input, and offers an optional front-mounted pneumatic test jack.

Key Attributes:

- Highly accurate and repeatable

- Excellent resistance to vibration and closed-loop feedback circuit

- High-density installation option

Semiconductor locations require tight temperature control of their HVAC systems. Semiconductor locations require tight temperature control of their HVAC systems.

![]()

Sometimes there are two separate systems that need to monitor temperature points; one for control and one for data archiving. Rather than wiring a 4-20mA signal in series through two host systems, consider using a signal splitter like the ECT. The UL approved ECT signal splitter allows both systems to monitor temperature but now neither system can affect the other when there is a failure or maintenance issue on the other loop.

Key Attributes:

- Full four-way isolation up to 500Vrms between power and all input/outputs

- RFI/EMI resistant and hardened aluminum case

- Zero and span potentiometers for on-site calibration

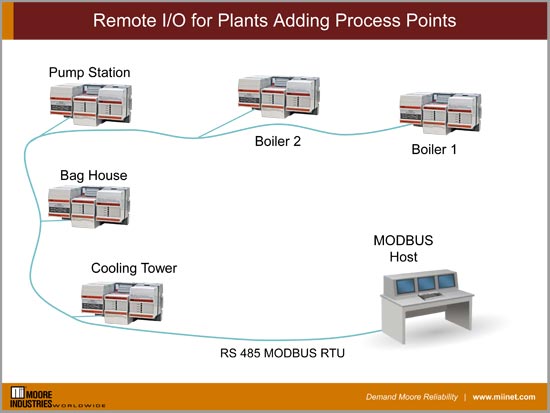

Power generation, water, and pulp & paper plants often have process points that are added after the initial plant build. Sometimes the DCS has run out of I/O points or spare twisted pair doesn’t exist. Many plants have process points that are added after the initial plant build. Sometimes the DCS has run out of I/O points or spare twisted pair doesn’t exist.

When such a requirement exists, the NCS Net Concentrator System remote I/O product simplifies the task of gathering signals scattered through multiple processing units or locations. The NCS is Class I Div 2/Zone 2 approved and accepts a wide range of inputs including RTD, TC, Ohms, Potentiometer, mV, mA and Volts. Each NCS remote I/O station can accept up to 128 I/O points. It supports RS-485 MODBUS RTU so up to 32 NCS systems without repeaters can be multi-dropped on one twisted pair and brought back to a MODBUS host monitoring system. The easy to configure NCS has 500V of channel-to-channel isolation and has an ambient operating temperature specification of -40 to 85C (-40 to 185F).

Key Attributes:

- The wide range of I/O types and number of points

- Class I Div 2/Zone 2 approval

- MODBUS RTU support

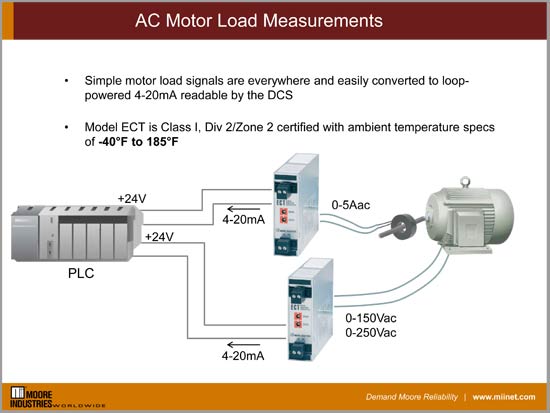

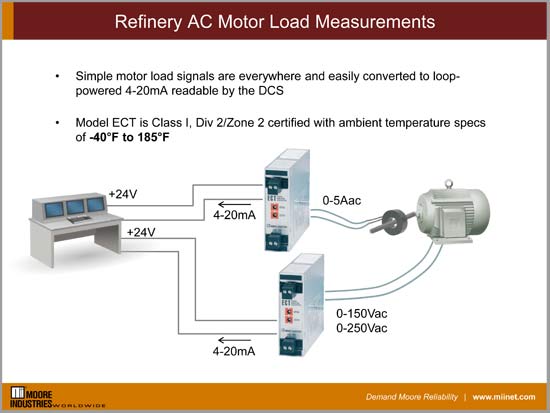

Many facilities have hundreds of motors installed throughout various processing units. Monitoring of these motors for more precise control or protection is paramount.

The model ECT is a Class I Div 2/Zone 2 DIN rail, loop-powered (two wire) signal converter with an operating range of -40 to 85C (-40 to 185F) that accepts AC current inputs of up to 0-5A AC and outputs a linear and noise-free 4-20mA signal readable by the BPCS or PLC. As an added safety feature, the ECT offers an optional externally mounted mini-CT (Current Transformer) that steps 0-5A AC down to 0-5mA AC so technicians don’t have to worry about handling high current signals. ECT also accepts high-level AC voltage inputs too.

Key Attributes:

- Two wire loop-powered AC signal converter

- Class I Div 2/Zone 2 approvals

- High ambient operating temperature range of -40 to 85C (-40 to 185F)

In order to keep Natural Gas pipelines operational, compressor stations are located every 50 miles or so. These compressors have critical temperatures that need to be monitored including bearing, lube oil, discharge and suction temperature. Due to the criticality of these temperatures a Safety Instrumented System (SIS) may be implemented to protect the compressor and personnel.

If an SIS is employed, the Class I Div 2/Zone 2 STA Functional Safety Trip Alarm, that is exida certified and SIL 2/3 capable, can provide the logic solver needs for the high-temperature shutdown circuit. The STA offers a simple programming interface, local indication, and retransmission of critical temperatures to a remote host or SCADA system.

Key attributes:

- STA is exida certified and SIL 2/3 capable logic solver

- Simple programming interface vs complex safety PLC

- Provides local indication and auxiliary analog output

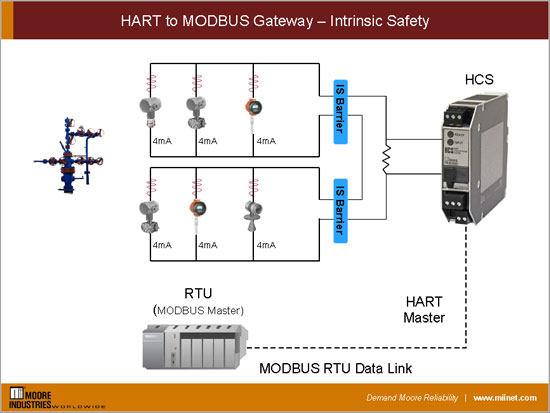

Upstream and midstream oil and gas locations are always looking for ways to cut costs. Since their sites typically have hazardous gasses and vapors present, their wiring methods and instruments have to be rated Class I Div 1.

One consideration to reduce your cost per point monitoring at these sites is to utilize the HCS HART Concentrator System by reading the HART signal from your field instruments. HART allows multiple instruments to be installed on a single twisted pair. Rather than using an individual twisted pair per instrument and Intrinsically Safe barriers or hard conduit, you can use one HCS and one IS barrier with multidropped instruments on one twisted pair and convert the HART data to MODBUS RTU. The HCS can accept up to 16 multidropped instruments. The actual number of multidropped transmitters is dependent upon the power your IS barrier allows into the field. The local RTU can then read multiple instruments via the MODBUS RTU signal. The HCS is approved for installation in Class I Div 2/Zone 2 areas and supports both RS-232 and RS-485 physical layer networks. The HCS is configured via a free Windows PC program and sets up in just a few minutes.

Key Attributes:

- Polls between one and 16 HART instruments and converts data to MODBUS RTU

- Class I Div 2/Zone 2 approval

- -40 to 85C ambient operating temperature

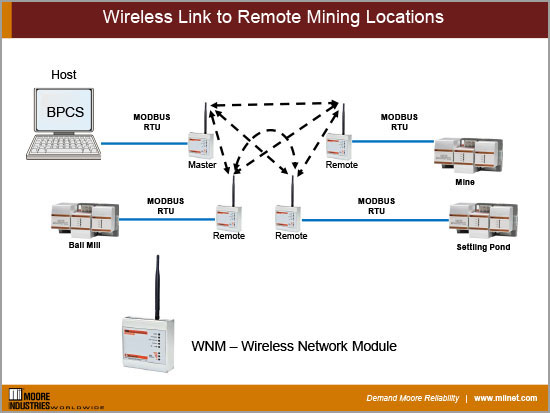

Mining facilities have far-reaching and remote locations that need to be monitored. Often these locations have limited wiring and are miles apart. Mining facilities have far-reaching and remote locations that need to be monitored. Often these locations have limited wiring and are miles apart.

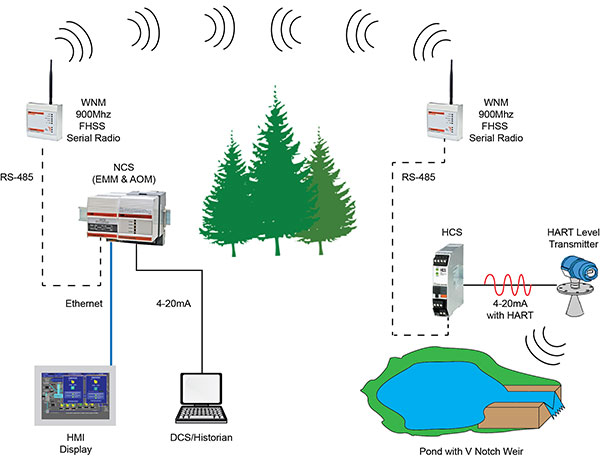

To solve this dilemma look to the WNM Wireless Network Module. The WNM is a 900Mhz or 2.4Ghz License Free Spread Spectrum Radio that can cover up to 30 miles (without repeaters) between locations. Each WNM can be programmed to be a Master, Remote, Repeater or Remote/Repeater. The WNM is certified for installation in Class I Div 2/Zone 2 locations and supports Ethernet and MODBUS RTU communication links, therefore, making it an ideal interface with almost all remote I/O systems, including the NCS Net Concentrator System shown here.

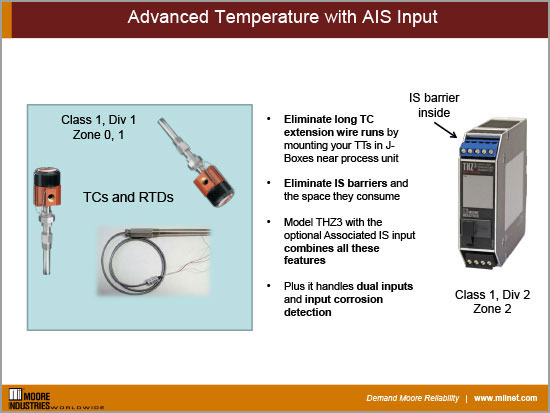

When temperature points need to be monitored in hazardous locations where explosive atmospheres can occur, consider using an Associated IS temperature transmitters, especially when the method of protection is Intrinsic Safety. When Intrinsic Safety (IS) is chosen as the facility's protection method, intrinsically safe barriers for all of the RTD and TCs can be quite expensive, engineering intensive and space consuming.

One solution to this problem is to install DIN rail temperature transmitters in the field, close to the process, that has built-in intrinsically safe barriers. The THZ3 DIN rail temperature transmitter is considered an associated IS device because it has the IS barrier embedded in the transmitter so it can connect to temperature elements that are located in Class I Div 1 or Zone 0/1 hazardous areas. Moreover, by implementing this strategy you eliminate the common drift and corrosion problems associated with long TC lead wire runs that lead to expensive and troublesome measurement errors.

Key Attributes:

- IS barrier built into THZ3, reducing needs for external IS barriers

- Eliminate errors due to TC extension wire

- Dual input capability and input corrosion detection

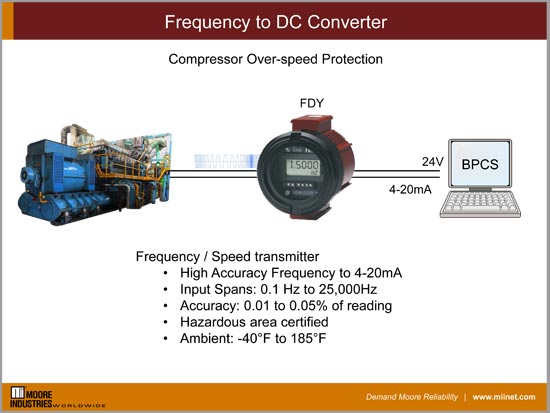

Industrial compressors are often used in large chemical plants to supply headers with air for pneumatic instruments and valves. These compressors have to run at precise speeds. If these compressors start to run too fast they can become very dangerous and expensive to repair. Industrial compressors are often used in large chemical plants to supply headers with air for pneumatic instruments and valves.

These compressors have to run at precise speeds. If these compressors start to run too fast they can become very dangerous and expensive to repair.

If you have compressors or rotating equipment that is critical, consider the FDY PC Programmable Frequency-to-DC Converter to help provide compressor overspeed protection. The FDY monitors frequency, period, high or low pulse width, and contact closure signals and converts it to a linear and isolated 4-20mA signal. The two-wire loop powered FDY has worldwide hazardous areas approvals and sets up in just a few minutes with easy to use PC programming software.

Key Attributes:

- Universal programmable input

- Local display and Free PC programming software

- Worldwide hazardous area approvals

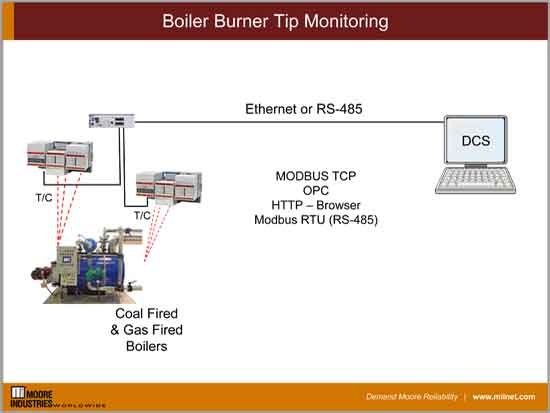

Steam generation is often a primary source for the heating of fluid processing, chemical processing units, and reactors and therefore maintaining efficient boiler control is critical. Boilers can sometimes suffer flameouts due to poor fuel quality or insufficient oxygen. TCs can be used to monitor boiler tips. Traditionally TCs were wired directly back to a BPCS or PLC with thermocouple extension wire.

Thermocouple extension wire is not only expensive but can be a source or measurement error over time due to the integrity and composition of the extension wire. When boiler tip monitoring is required consider using the NCS Net Concentrator System remote I/O. The NCS accepts universal temperature inputs and is scalable for just a few or hundreds of I/O points. Each NCS can then be placed on an Ethernet backbone for centralized monitoring. If Ethernet is not an option the NCS also supports RS-485 MODBUS RTU networks. Every NCS channel provides 500Vrms channel-to-channel isolation which is important for thermocouples. Approved for installation in Class I Div 2/Zone 2 locations, the NCS is an ideal choice when you need a compact remote I/O solution.

Key Attributes:

- Universal temperature inputs

- Full channel-to-channel isolation

- Ethernet or RS-485 network support

Australia exported $34 billion in coal in 2015-2016 which has made it the largest global coal exporter by volume (Australian Government, 2016). There are 44,000 people directly employed in the coal industry making safety in mines an important issue. Moore Industries works hard to provide peace of mind with the reliability and ruggedness industry has come to depend on. The Moore Industries FS FUNCTIONAL SAFETY SERIES exida® SIL 2 and SIL 3 capable STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions to meet the needs of safe mine transportation.

Australia exported $34 billion in coal in 2015-2016 which has made it the largest global coal exporter by volume (Australian Government, 2016). There are 44,000 people directly employed in the coal industry making safety in mines an important issue. Moore Industries works hard to provide peace of mind with the reliability and ruggedness industry has come to depend on. The Moore Industries FS FUNCTIONAL SAFETY SERIES exida® SIL 2 and SIL 3 capable STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions to meet the needs of safe mine transportation.

The Problem

Properly working underground coal mine hydraulics, used to operate the control of the braking system of the winder, is vital when moving mine personnel underground or bringing them to the surface. It is extremely important to ensure that the machine is stopped if low or high pressure is detected online from the hydraulic pump that operates the winder. With personnel safety involved, we can't afford any cable slip.

The Solution

The STA, SIL 2 and SIL 3 Capable Programmable Current/Voltage Safety Trip Alarms are utilized for mine winder monitoring. The STA warns of unwanted process conditions, provides emergency shutdown, or provides on/off control in Safety Instrumented Systems (SIS) as well as traditional alarm trip applications.

The STA makes an excellent choice for monitoring hydraulic pressure on the Mine Winder and assuring it will shut down the winder should any pressure changes occur.

Contact Moore Industries-Pacific Basin/Asia for your needs in Australia.

References

Australian Government, Department of Industry, Innovation, and Science. (2016, December). Australia's major export commodities coal. Retrieved from https://industry.gov.au/resource/Mining/AustralianMineralCommodities/Documents/Australias-major-export-commodities-coal-fact-sheet.pdf

Do you want more information? Check out the STA datasheet or the Functional Safety - IEC 61508 line card line card.

Need to know more about a product, price or availability? Send us a message using E-Help.

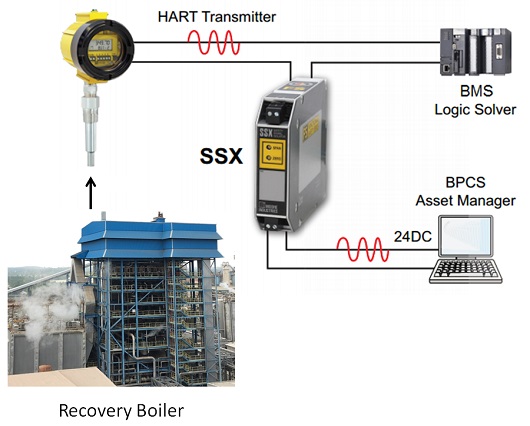

The Problem

A pulp and paper mill had a black liquor BMS (Burner Management System) that per NFPA 85 requires that its safety logic system be totally independent from other logic systems. The challenge was they required that key temperature and pressure signals also get monitored and recorded by their BPCS (Basic Process Control System).

The Solution

The SSX Functional Safety Isolator with HART pass through capability was designed for Safety Instrumented Systems (SIS) and safety applications. The SSX is designed to provide full isolation between a safety system and a non-safety system. The two-wire loop-powered SSX has a passive input and is powered by the output loop side that is connected to the BPCS. Therefore even if power is lost on the BPCS side of the loop, the safety loop functions without interruption. According to IEC 61508 the SSX is a Type A device and per exida is suitable for SIL 3 applications. An exida approved FMEDA report is provided for the SSX safety isolator to assist the safety practitioner with the safety loop implementation.

Learn more about the SSX Functional Safety Isolator and the entire family of Moore Industries Functional Safety Series.

Need to get price or availability or have a technical question? Send us a message using E-Help.

At the Hanford Site KW-Basin Sludge Treatment Project in southeastern Washington, the Department of Energy (DOE) employs multiple NCS Net Concentrator Systems to automate communications among numerous sludge conversion process skids. According to Hanford’s website:

At the Hanford Site KW-Basin Sludge Treatment Project in southeastern Washington, the Department of Energy (DOE) employs multiple NCS Net Concentrator Systems to automate communications among numerous sludge conversion process skids. According to Hanford’s website:

“Nowhere in the DOE Complex is cleanup more challenging than at the Hanford Site in southeastern Washington. Hanford made more than 20 million pieces of uranium metal fuel for nine nuclear reactors along the Columbia River.

Five huge plants in the center of the Hanford Site processed 110,000 tons of fuel from the reactors, discharging an estimated 450 billion gallons of liquids to soil disposal sites and 56 million gallons of radioactive waste to 177 large underground tanks. Plutonium production ended in the late 1980s.

Hanford cleanup began in 1989, when a landmark agreement was reached between DOE, the U.S. Environmental Protection Agency, and Washington State. Known as the Tri-Party Agreement, the accord established milestones for bringing the Hanford site into compliance with federal and state environmental regulations.”

Hanford cleanup began in 1989, when a landmark agreement was reached between DOE, the U.S. Environmental Protection Agency, and Washington State. Known as the Tri-Party Agreement, the accord established milestones for bringing the Hanford site into compliance with federal and state environmental regulations.”

However, as skids were progressively added, management recognized they were outgrowing manual intervention methods and NCSs (Net Concentrator System) were installed and programmed in order to allow automatic communication among the skids. Production personnel could now oversee the process from a control room rather than walking the production floor and could redirect communication links through various skids should some skids be underutilized or offline.

Each sludge processing skid includes a Moore Industries NCS that includes an Ethernet communications port and several channels of discrete and analog input/output channels.  These channels monitor skid mounted gauges and control valves/gates. The NCS also has an embedded real time control engine that supports IEC 1131-3 control logic communication programming via ISaGRAF software.

These channels monitor skid mounted gauges and control valves/gates. The NCS also has an embedded real time control engine that supports IEC 1131-3 control logic communication programming via ISaGRAF software.

Utilizing the ISaGRAF programming language, Hanford engineers were able to write their own programming instructions. The ISaGRAF program is also used to provide peer-to-peer Ethernet communications between other skids establishing convenient communications to share data.

Each NCS skid performs a particular part of the overall process, very similar to a batch process that carries out a particular complex recipe. During the process, each NCS skid collects, controls and monitors each part of its own process.

Every skid also monitors, triggers and makes available process flags, or status bits, to the control room personnel and other NCS skids. These status bits are used by other skids to determine if the next skid may collect the processed product from an upstream skid and begin processing the product itself (this being another sub-process).This continues for several levels in the process with each skid performing a different step in the sub-processes of the overall process. Some skids coordinate steps in the process (as described above) while other skids are the ‘traffic cops’ negotiating which skid is ‘available’ to handoff product to the next stage. The arrangement is such that skids may be taken ‘off-line’ or added ‘on-line’ with the automatic traffic cop logic to decide where product is to be rerouted. A separate skid acts as the ‘accountant’ keeping count on system productivity and bottlenecks including which skids are currently ‘off-line’.

The NCS’ ISaGRAF programming ease and flexibility, onboard Ethernet communications and peer-to-peer channel mapping allows new and existing skids to be automated or retrofitted as required. This enables the Hanford site to handle the increased sludge processing throughput without overburdening their process team.

To learn more about the Hanford Site cleanup, visit www.hanford.gov

For more information download the NCS Net Concentrator System data sheetdata sheet.Or visit the catalog.

Need to get price or availability or have a technical question? Send us a message using E-Help.

Supplemental Information For Tank Farm Application

Before converting a dry contact to an analog signal it is important to first determine what signal levels you will need. Since the TMZ accepts a 4-20mA signal then we can choose any current values within 4mA and 20mA. For this application we chose 'NOT FULL' to be equal to 20mA, and 'NEAR FULL' to be represented at 4mA.

These two current levels will now indicate that the tank is ‘NEAR FULL’ or ‘NOT FULL’. The ‘NEAR FULL’ signal lets the DCS operator know that the tank should not be filled any further while the ‘NOT FULL’ indicates that the tank needs additional filling.

Using resistors in conjunction with a 24Vdc power supply, based on Ohm's law, allows a discrete or relay signal to be converted to an analog signal. Using ohm’s law the two resistors chosen for the desired analog signal levels were 1.5K Ohms and 6K ohms. If the tank level is low, then the circuit includes both resistor values thus creating a 20mA signal to the TMZ. This 20 mA reports ‘NOT FULL’.

V=IR

(24V/1500Ω) + (24V/6000Ω)

16mA + 4mA = 20mA

Otherwise, when the contact switches only the 6K ohm resistor is in the circuit and a current signal of ~4mA indicating ‘NEAR FULL’ (this occurs when the dry contact switch is open).

These two signal levels 4mA and 20mA will be converted to a logical “1” and “0” for MODBUS transmission. Those TMZ specific programming details will be covered later.

Wiring Details

The bulk 24dc power supply, two resistors and contact terminals on the level transmitter need to be wired as a current input to the TMZ utilizing +I and COM terminals (See Figure 1).

Figure 1. Top of TMZ highlighting connections

This wiring configuration creates a “failsafe” situation. For example, should the level switch accidentally fail to open, or the 24Vdc become short circuited, then that tank is reported ‘NEAR FULL’ (4mA signal). A detailed wiring schematic can be found in Figure 2.

Figure 2. Tank Wiring and Setup

- The float cage signal is converted using resisters (6000Ω and 1500Ω)and a regulated bulk 24Vdc power supply, connected to the TMZ, which is then connected to the RS-485 port (MODBUS) of the new WNM.

- The TMZ converts the analog signal to a MODBUS output that is connected to the WNM's RS-485 port.

- The WMN, also powered by the existing bulk24Vdc power supply, transmits signals wirelessly from the new tanks across the river to theWNM radio network connected to the DCS’ MODBUS network.

Details on Configuring the TMZ Transmitter to Communicate Data via MODBUS

Use the Model TMZ programming cable and free programming software to configure the Model TMZ for each tank. Assign a MODBUS address to this storage tank TMZ. Configure the baud rate, parity, etc. to match that of all other MODBUS devices.

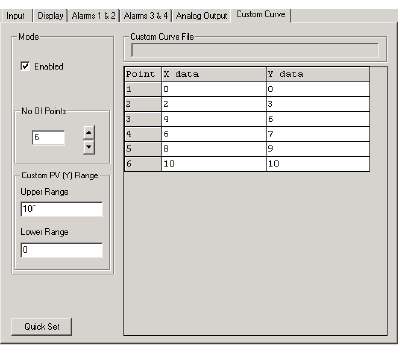

Configure the Model TMZ ‘Custom Curve’ feature such that current less than 5mA is ‘0.0’ (‘NOT FULL’) and current above 19mA is ‘1.0’ (‘NEAR FULL’).

(Note: This was chosen as the customer preferred the valve state for filling the tank to be 0 for open, and 1 for closed).

For example, a simple four point custom curve like the following will work:

Figure 3. Four Point Custom Curve

| Point | X Data | Y Data |

| 1 | 4 | 0 |

| 2 | 5 | 0 |

| 3 | 19 | 1 |

| 4 | 20 | 1 |

WNM Configuration and MODBUS Network Wiring

Configure the Model WNMs as point-to-point radios and choose all other settings as required. Moore Industries Application support pre-configures the WNMs prior to shipment from the Moore Industries factory, making the WNMs ‘ready-to-use’ upon arrival.

Wire the Model TMZ and WNMs to the twisted pair MODBUS network. See TMZ and WNM instruction manuals for RS-485 wiring diagram.

Have questions, or want help with your application?

To learn more about this application, read the Tank Farm Application and Monitoring Solution page.

If you have questions or need help on your own application, send us a message using E-Help.

If you want product information, visit the catalog.

The Problem:

A Moore Industries customer wanted to monitor levels in new storage tanks that are remotely located on their tank farm and are not connected to their existing MODBUS network. The details of the customer’s existing tank farm, recent additions and monitoring needs include:

Twenty existing tanks are monitored using MODBUS continuous level sensors with data transmitted over a RS-485 twisted pair network.

Five new remote tanks were added and need to be monitored, but were built with a level sensing device that only provided a dry contact output from a float cage to indicate level, no MODBUS output available.

The customer needs to convert the dry-contact output from the new remote tank level devices to a MODBUS signal that indicates two level states: NEAR FULL or NOT FULL and then transmit the data via MODBUS for monitoring at the Distributed Control System (DCS).

The new remote tanks could not be connected to the existing MODBUS network using twisted pair wire because they are located across a river from the existing tanks and the DCS.

The Solution:

Summary

Moore Industries Applications Engineers provided the customer with a cost effective and simple solution for monitoring their new storage tanks that utilized their existing technologies. After reviewing their situation the following issues needed resolving:

- Dry-contact (discrete) output to analog signal conversion

- Analog signal to MODBUS translation

- Getting the signals to the DCS from the tanks across a river

The first step involved using a pair of resistors and a bulk DC power supply to convert the dry-contact relay output from each tank’s float cage to a 4-20mA signal. Next a Moore Industries TMZ PC-Programmable MODBUS Transmitter (Signal Converter) was used to read and convert the 4-20mA signal into MODBUS. And finally the new MODBUS signals had to be connected to the existing MODBUS network across the river. This involved installing a pair of Moore Industries WNMs (Wireless Network Modules) that utilized a point-to-point wireless network link across the river.

Figure 1. below shows the Tank setup with dry-contact outputs in a float cage, resistors, TMZ transmitter, and the WNM wireless module necessary to add the five new tanks to the MODBUS network and DCS across the river.

Figure 1. Tank Wiring and Setup

- The float cage signal is converted using resisters (6000Ω [4mA for current loop one float level] and 1500Ω [an 'additional 16mA' to signal other float level]) and a regulated bulk 24Vdc power supply, connected to the TMZ, which is then connected to the RS-485 port (MODBUS) of the new WNM.

- The TMZ converts the analog signal to a MODBUS output that is connected to the WNM’s RS-485 port.

- The WMN, also powered by the existing bulk 24Vdc power supply, transmits signals wirelessly from the new tanks across the river to the WNM radio network connected to the DCS’ MODBUS network.

Installation Specifics

Dry Contact Output and MODBUS Conversion

To solve the problem of getting level data from dry contacts into the existing MODBUS network, the Moore Industries application engineer suggested using a bulk 24dv power supply, a set of resistors and a TMZ MODBUS transmitter to be installed on each new storage tank. The TMZ (Model TMZ/HLPRG/MB/24DC [DIN]) is a very cost effective and flexible instrument. It accepts a direct signal input from a wide array of analog devices and converts the input to the standard MODBUS RTU (RS-485) communication protocol for direct interface with MODBUS-based monitoring and control systems.

The TMZ is powered in this application using a 24Vdc power supply at each new tank location. This same bulk power supply was then used in conjunction with resistors to convert the dry contacts to an analog signal (DC milliamps) that the TMZ could read. The engineer connected the dry contacts’ two discrete terminals to the TMZ using a pair of resistors, 6000Ω and 1500Ω, to create a current loop signal representing the two different tank levels.

The TMZ translates the analog signal to a digital MODBUS communications signal. Each TMZ was then connected to a RS-485 twisted pair network that was routed from tank to tank. Each storage tank TMZ has a unique MODBUS address assigned by the installer, which allows the DCS to distinguish individual tank level data.

Wireless Transmission

The Moore Industries WNM Wireless Network Module used in this application is a bi-directional, point-to-point or point-to-multipoint, 900 Mhz frequency hopping spread spectrum radio modem that includes a RS-485 port. In order to connect the two MODBUS networks together across the river, a set of WNMs was used in point-to-point configuration. Each WNM can also be simultaneously configured as a tank site source and a wireless repeater, allowing for virtually unlimited transmission range. Since the customer already had a MODBUS RTU data communication network, the WNM’s RS-485 port made it an ideal choice for this application.

At the new storage tank, the engineer installed a Model WNM radio and connected it to the newly installed MODBUS RTU network. The MODBUS RTU communications signal received by the WMN over the twisted pair wires is transmitted by an antenna to the peer WNM radio that is now connected to the original MODBUS network and DCS across the river. This essentially created an extension to the existing MODBUS RTU network through the radios. This now allows bi-directional communication between the DCS and any tanks located across the river.

Get more detail on how the dry contacts were converted to an analog signal, and how the TMZ is configured to convert 4-20mA signals to MODBUS, see supplementary information.

If you have questions or need help on your own application, send us a message using E-Help.

If you would like product information, visit the catalog.

Moore Industries-Pacific recently sold 221 STA Safety Trip Alarms to be used in a Functional Safety coal gas extraction application in Australia. A Coal Seam Gas exploration company with hundreds of sites in Queensland has production wells with up to 10 inputs controlled locally by Remote Terminal Units (RTUs). The STA will be implemented as part of their independent Protection System with a level alarm on each wellhead separator. Larger volume production wells may need up to four separators per RTU panel.

The Coal Seam Gas exploration company has been using our SPA2 alarms in this application since 2005. Their reliability and simplicity of programming have made Moore Industries the company’s first choice alarm provider. They chose the STA over the SPA2 for this project due to the fact that the STA is a SIL 3-capable device and provided additional diagnostic coverage to continually check the alarm trip's operational status and health.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question? Send us a message using E-Help.

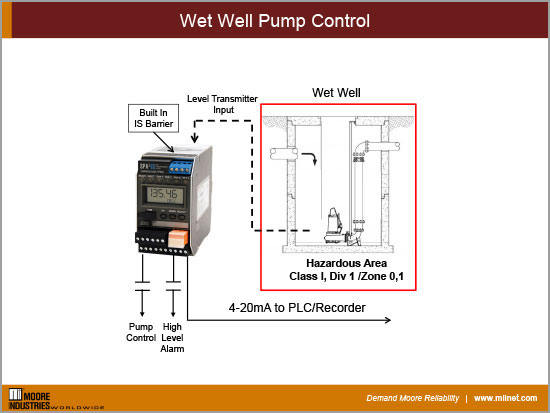

Municipalities often have several wet well locations around a city that pump waste from low lying areas up to main sewage veins that feed waste treatment plants. Level instruments monitor the wet well level and controllers then engage the grinder pumps. Since wet wells contain waste, volatile gasses such as methane require that these level instruments be rated for use in Class I, Div 1 environments.

When IS (Intrinsic Safety) is chosen as the method of protection, a separate IS barrier is required for each level transmitter that is wired to the pump controller. The SPA2IS Site Programmable Alarm with Associated IS Input capability includes a built-in IS barrier for the level instrument located in the wet well. This means that the separate IS barrier does not have to be purchased, installed and maintained. The SPA2IS has four alarms, each configurable with 0-100% deadband, which makes it an ideal fit for a wet well level controller.

Key Attributes:

- Includes built-in IS barrier for hazardous sensors and transmitter connection

- Easy to program with local push buttons or free PC software

- Up to four alarms with an auxiliary analog output

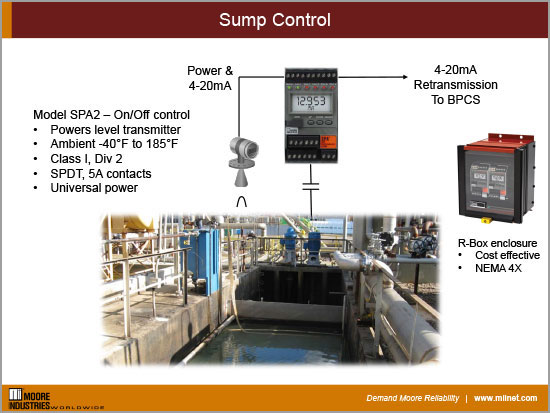

Water and waste facilities, whether local or remote, have many locations where sump monitoring and control are required. When it isn’t economical to use a PLC or due to its remote distance away from other control loops, an advanced alarm trip may do the job.

The SPA2 Site Programmable Alarm Trip is a very versatile and smart device that allows you to control as many as four pumps or motors simultaneously. The SPA2 has up to four programmable SPDT relays all rated at 5A, 250VAC that can be programmed has high or low with adjustable time delays and deadbands that make it an ideal candidate for on/off level control. Additionally, the unit has a universal power supply, powers the level transmitter that it monitors and features an auxiliary analog output in case there is a need to retransmit the level reading. Rated Class I Div 2/Zone 2 the unit includes an integrated display and is programmable via the local pushbuttons or with a free intelligent PC program. Designed for remote and outdoor locations the SPA2 operates in ambient conditions of -40 to 85C (-45 to 85C).

Key Attributes:

- Four SPDT Relays rated at 5A, 250VAC

- Class I Div 2/Zone 2 approval

- Programmable for on/off control with adjustable deadband and auxiliary output

Fabrication rooms in semiconductor facilities require close monitoring of humidity. Often getting the humidity reading in the middle of the room is ideal, close to the wafer machine.

![]()

When this is required, consider the flexible humidity probe for the HTZ Humidity and Temperature Transmitter. The flexible sensor is an armored cable up to 10 feet long that can be mounted through the ceiling through a 1” NPT coupling and adjusted downward to the desired measuring point. The HART programmable HTZ has a remote display and has two analog outputs that can be programmed to output humidity, temperature or dew point.

Key Attributes:

- Versatile flexible humidity sensor design

- +/- .75% humidity measurement

- HART programmable with two outputs and local display

Semiconductor facilities require close monitoring of humidity in their HVAC and fab rooms. The HTZ Humidity and Temperature transmitter has a versatile duct mounted sensor assembly that is ideal for monitoring humidity and temperature in a duct.

![]()

Additionally, the sensor can be wall mounted for clean room humidity and temperature monitoring. The HART programmable HTZ has a remote display and has two analog outputs that can be programmed to output humidity, temperature or dew point.

Key Attributes:

- Versatile duct mount/wall mount designed humidity sensor

- +/- .75% humidity measurement

- HART programmable with two outputs and local display

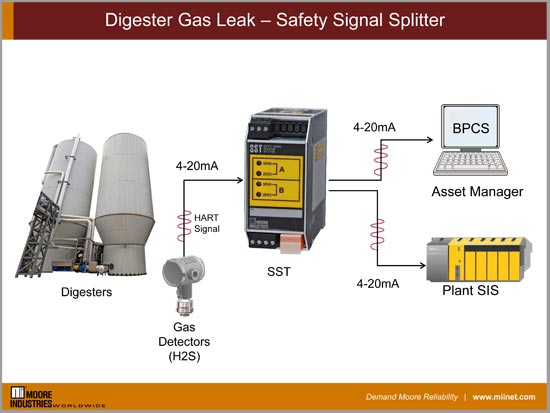

The cooking process that takes place in digesters at paper mills produces off gasses like hydrogen sulfide that, should they be accidentally released, could cause immediate suffocation of plant personnel. For this reason, gas detectors are placed in low lying areas where gasses that are heavier than air can immediately be detected.

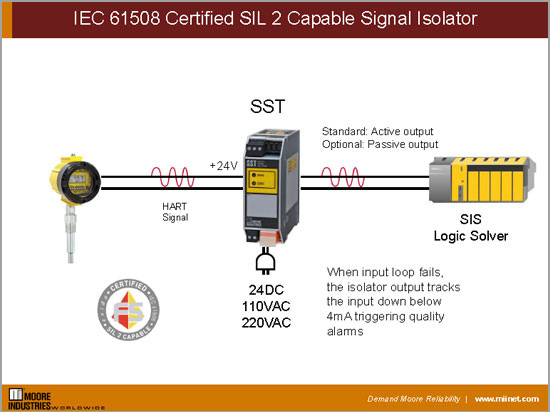

Due to the dangerous nature of this potential leak Safety Instrumented Systems (SIS) are often implemented. Often these gas detectors are also monitored by the Basic Process Control System (BPCS) too. When this is a requirement, look to the Functional Safety Series SST Safety Splitter. The four-wire SST is an exida approved SIL 2 capable signal splitter, with Class I Div 2/Zone 2 approval, that sends your critical process signal to two remote locations. The SST also passes valuable HART diagnostic and process variable data through the SST in case asset managers need to view calibration or other essential diagnostic data from the field transmitter.

Key Attributes:

- exida approved and Class I Div 2/Zone 2, SIL 2 capable for SIS loops

- Full four-way isolation up to 500Vrms between power and all input/outputs

- Passes critical HART data from field transmitter

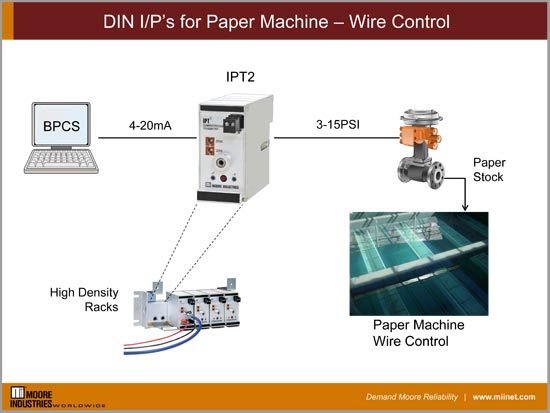

The wet end of large paper machines requires precise control of the paper stock as it is laid on the wire. Normally several small valves are evenly spaced across the wire to ensure a uniform distribution of paper stock.

Since these wire control valves are too small to accommodate a field mounted I/P or positioner, the highly accurate and repeatable two-wire loop powered IPT2 DIN mount Current-to-Pressure transmitter is a perfect solution. The IPT2 can be rack mounted for high-density installations in 5, 10 or 15 position racks that simplify air supply, filtering and regulation due to its backplane header design. The IPT2 includes a pneumatic closed loop feedback circuit for optimum control, has front mounted test leads to monitor the input and offers an optional front mounted pneumatic test jack.

Key Attributes:

- Highly accurate and repeatable

- Excellent resistance to vibration and closed loop feedback circuit

- High-density installation option

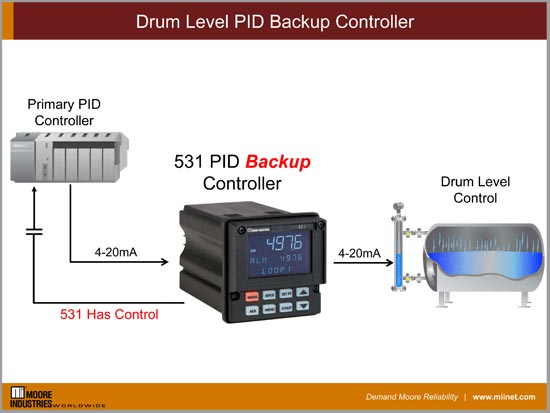

Drum level control for a boiler at Power plants is very critical to daily operations. If there was a fault with the primary controller handling the PID level control, it is quite likely that power product would stop or be severely hampered.

Consider the ¼ DIN 531 Hot PID Backup Station for these and other mission-critical applications. The 531 is specially designed for applications where it is the secondary control master on critical loops. In normal operations the 531 simply monitors the 4-20mA signal passing through it to the final control element. If there is a catastrophic failure of the primary PID controller, the 531 picks up where the primary left off and takes over PID control. A notification is sent to the primary controller or other watchdog systems to let facility operations know that there has been a problem and the secondary PID controller has taken over. The 532 features a large vacuum fluorescent display with a large five digit upper display and two nine-character lines of alphanumerics.

Key Attributes:

- Easy to configure

- HOT PID Backup station

- Large display with local indication of PV and CV-Nema 4X case with UL Approval

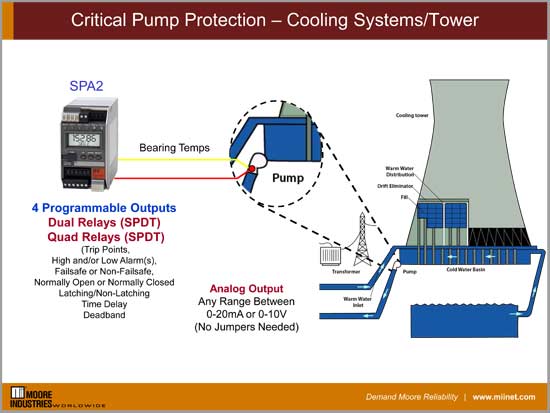

Pumps are extremely critical devices at Power facilities. If pumps fail, turbines and other key parts of the power generation plant will be shut down. One common point of failure in pumps is bearing failure. Most large pumps have bearings that wear out over time and temperature is normally a good way to monitor the pump bearings looking for wear or simply to perform routine maintenance. While control systems can monitor pumps many times these pumps are remote to the control room.

Using a TC or RTD and a SPA2 Site Programmable Alarm Trip is an effective local layer of protection strategy. The Class I Div 2/Zone 2 SPA2 includes up to four programmable SPTD relays rated at 5AAC that can be programmed to warn of pending pump failure. Powered with a universal power supply the SPA2 can be programmed via the local pushbuttons or with free PC programming software and a USB cable.

Key Attributes:

- Universal temperature sensor input

- Four programmable relays rated at 5AAC, 250VAC

- Easy programming and universal power supply

Petrochem facilities have hundreds of motors installed throughout various processing units. Monitoring of these motors for more precise control or protection is paramount.

Click here to download the PDF file

The model ECT is a Class I Div 2/Zone 2 DIN rail, loop-powered (two wire) signal converter with an operating range of -40 to 85C (-40 to 185F) that accepts AC current inputs of up to 0-5A AC and outputs a linear and noise free 4-20mA signal readable by the BPCS or PLC. As an added safety feature, the ECT offers an optional externally mounted mini-CT (Current Transformer) that steps 0-5A AC down to 0-5mA AC so technicians don’t have to worry about handling high current signals. ECT also accepts high-level AC voltage inputs too.

Key Attributes:

- Two wire loop-powered AC signal converter

- Class I Div 2/Zone 2 approvals

- High ambient operating temperature range of -40 to 85C (-40 to 185F)

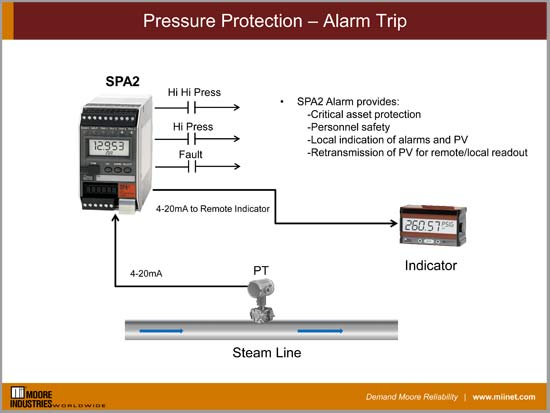

Refineries and petrochemical plants use steam to heat vessels and different parts of their process units and if steam pressure rises too high it could create a dangerous situation. Monitoring and alarming on steam pressure adds a layer of protection for personnel and process. But many times these points are remotely located where it isn’t practical to run multiple twisted pairs to and from the control room or closest PLC.

Click here to download the PDF file

When remote alarms or layers of protection are required, look to the SPA2 Site Programmable Alarm Trip. The SPA2 is push button or PC programmable alarm trip, or trip amp, that offers high, low, rate of change, fault, out of range, input failure alarm types. Fitted with a universal power supply, it has up to four programmable SPDT alarms with an optional auxiliary analog output and a loop power supply for powering two-wire transmitters. The SPA2 is approved for installation in Class I Div 2/Zone 2 locations.

Key attributes:

- Versatile and easy programming with push buttons or PC software

- Up to four SPDT relays rated at 5A 250VAC/24VDC

- Suited for installation in Class I Div 2/Zone 2 locations

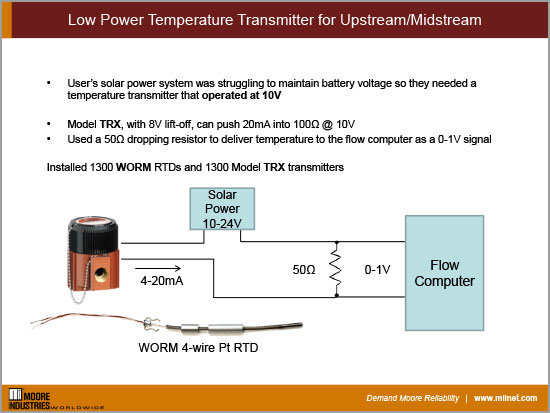

Upstream/Midstream oil and gas wellhead sites are in remote areas that often rely on solar power to run instrumentation and monitoring systems. During winter months maintaining voltage levels from their solar sources is challenging and finding instruments that have minimum power requirements is critical.

Click here to download the PDF file

The model TRX Temperature Transmitter only requires eight volts to operate and can push 20mA through 100 ohms at 10 volts. By utilizing a 50 ohm dropping resistor a 0-1 volt signal representing temperature can be efficiently transmitted to the onsite flow computer.

Key attributes:

- Low eight volt liftoff for TRX Temperature Transmitter

- TRX Universal Input for any TC or RTD

- Full hazardous area approvals

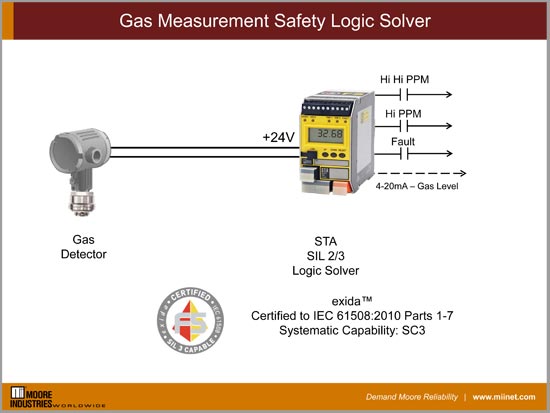

Many mining locations require layers of process protection to prevent unnecessary exposure to dangerous situations that may harm personnel or the environment, like gas exposure. Most mining operations have implemented Safety Instrumented Systems (SIS) in compliance with IEC 61511 to mitigate the exposure to such dangerous events.

When required to add layers of protection at the mine site, consider the STA Functional Safety Trip Alarm as your Safety Instrumented System logic solver when a dangerous condition occurs. The STA is simple to program and has an auxiliary analog output for retransmission to the local RTU. The STA is SIL 2/3 capable, approved by exida and rated for installation in Class I Div 2/Zone 2.

Key attributes:

- exida approved, SIL 2/3 capable

- Easy programming

- Class I Div 2/Zone 2 approval and local display

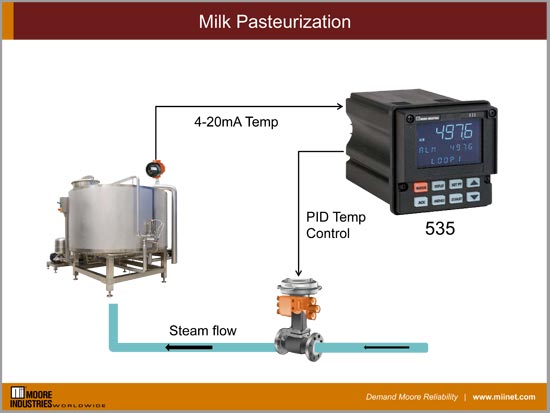

Milk producers are required to ensure proper pasteurization takes place before their products can be delivered for consumption. This requires tight temperature control and monitoring.

When pasteurization or sterilization is required to look to the NEMA 4x Model 535 ¼ DIN PID Controller. This versatile yet easy to program controller can perform P, PI or PID control with built-in auto-tuning and other advanced programming features. The controller features a large vacuum fluorescent display with a large five digit upper display and two nine character lines of alphanumerics. In addition to the CV (Control Variable) output, up to three additional relay or analog outputs can be configured.

Key Attributes:

- Easy to setup and configuration menu

- Easy to use PID auto-tuning

- Large display and additional outputs

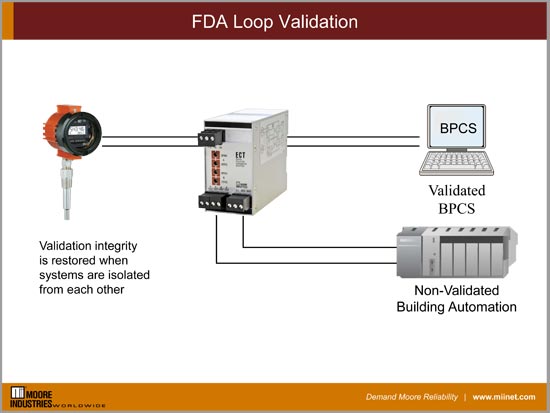

Food and beverage and pharmaceutical companies have several processes that require validation due to FDA and other international safety laws. When some measurements need to be shared between the primary process control system that is validated and an auxiliary control system, like building automation, it requires full isolation.

When this need arises using an ECT DIN Signal Splitter Isolator that provides the sufficient area isolation to meet validation needs. The UL approved ECT signal splitter now allows the non-validated system to be brought offline and calibrated separately without affecting the calibration or operation of the primary validated loop.

Key Attributes:

- Full four way isolation up to 500Vrms between power and all input/outputs

- RFI/EMI resistant and hardened aluminum case

- Zero and span potentiometers for onsite calibration

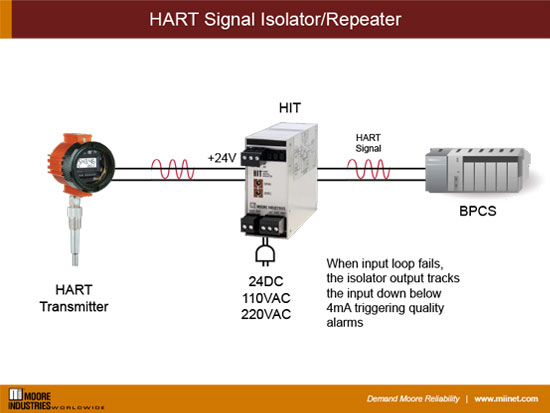

You can’t always plan for every loop condition in a chemical plant. Sometimes input cards are active and sometimes passive. Field transmitters are sometimes line powered (four-wire) which usually have active outputs, and sometimes they are passive (two-wire). Has the Basic Process Control System been updated with HART smart input cards? Has there been a new asset manager installed that needs the HART signal?

When those unplanned situations exist, you can turn to the HIT HART Pass-through Signal Isolator. The HIT isolator provides superior noise rejection and full three-way isolation with HART pass-through capability. Another very important feature of the HIT is that the output will track the input all the way to 0mA when it fails; as opposed to most other isolators that simply go to 4mA – which is always difficult to ascertain between a failure of the input or just 0% scale. Lastly, the HIT can be used on non-HART or HART based loops when asset managers need that valuable diagnostic and calibration data.

Key Attributes:

- Class I Div 2/Zone 2 approval

- HART pass-through capability

- Output tracks to 0mA on failed input

When Safety Instrumented Systems (SIS) are applied within a chemical facility you can’t always plan for every loop condition. Sometimes input cards are active and sometimes passive. Field transmitters are sometimes line powered (four-wire) which usually have active outputs, and sometimes they are passive (two-wire). Moreover, is the field transmitter HART capable or not?

When those unplanned situations exist, you can turn to the Functional Safety Series SST Signal Isolator. The SST is an exida approved four-wire SIL 2 capable isolator that provides superior noise rejection and full three-way isolation with HART pass-through capability. Additionally, the input to the SST can be wired in the field as an active input (applies power to the two-wire field transmitter) or passive input. The output of the SST can be ordered as active or passive. Another very important feature of the SST that is very critical for an SIS, is that the output of the SST will track the input all the way to 0mA when it fails; as opposed to most other isolators that simply go to 4mA – which is always difficult to ascertain between a failure of the input or just 0% scale.

Key Attributes:

- exida certified to SIL 2

- HART pass-through capability

- Output tracks to 0mA on failed input

An overpressure situation in pipes is dangerous and can lead to significant damages to property, pipe ruptures and even injuries and death. Having a system in place to prevent an overpressure situation is critical and one way to accomplish this is with a High Integrity Pressure Protection System (HIPPS).

A HIPPS provides a barrier between high pressure and low-pressure parts of an installation to prevent the release of fluid or gas into or otherwise contaminate the environment. An example of a HIPPS is an offshore well platform where the subsea oil or gas lines can occasionally present a harmful pressure surge in the pipeline. The HIPPS is designed to shut off the source before the design pressure of the downstream process is exceeded, avoiding a rupture of a line or vessel.

A HIPPS provides a barrier between high pressure and low-pressure parts of an installation to prevent the release of fluid or gas into or otherwise contaminate the environment. An example of a HIPPS is an offshore well platform where the subsea oil or gas lines can occasionally present a harmful pressure surge in the pipeline. The HIPPS is designed to shut off the source before the design pressure of the downstream process is exceeded, avoiding a rupture of a line or vessel.

A HIPPS consists of three main components:

•Pressure transmitters

•Logic solvers

•Fast-acting shutoff valves

Many people assume that the logic solver has to be a safety PLC. But in many cases, a discrete logic device for each loop, which avoids the complications and expense of a programmable solution, is a sensible option. The “Logic Solvers for Overpressure Protection” white paper shows how discrete logic devices such as the STA Safety Trip Alarm are suitable for use while providing a flexible, low-cost and user-friendly solution.

While the safety PLC approach offers advantages for installations where there are a high number of field I/O safety loops, many plants have few such loops. For these plants, discrete logic solutions offer several advantages including creating a simple architecture, reducing cabling costs and avoiding the development cost of application programming.

The STA is easy to install with its wide range of power supply options and its small package that helps to keep it separate from non-safety instrumentation. In the event of maintenance due to transients or failure, it can be readily swapped out at a low unit and operational cost without interfering with the other processes in the plant. Local indication gives reassurance that the status of safety loops is reported directly.

The “Logic Solvers for Overpressure Protection” white paper shows safety engineers the steps needed to determine the right logic solver for their SIS. It shows the methodology and calculations for determining the applicability of logic solvers in SIL 1 and SIL 2 environments. It includes examples of system topologies and their associated Safety Integrity Level (SIL) calculations.

The STA Safety Trip Alarm is part of Moore Industries’ FS Functional Safety Series of instruments. Each of these instruments is designed and built in compliance with IEC 61508, the leading worldwide functional safety standard, and certified by exida for use in a Safety Instrumented System. In addition to our FS Series of products FMEDA (Failure Modes Effects and Diagnostic Analysis) reports available on many of our products that are used in safety applications.

Find out more information about these products at the FS Functional Safety Series section of our website. You can also download the related “Logic Solvers for Tank Overfill Protection” white paper.

Q: We have an existing Rosemount 1151DP tied to a Provox DCS. We also have a Moore Industries DDA 4-Wire Current and Voltage Alarm in the system to provide a Flow Switch Low and Flow Switch High interlock to our gas supply valves. Will newer products from Moore Industries provide more – or better – protection than the DDA?

A: The STA Safety Trip Alarm and SPA2 Site Programmable Alarm have alarm functions and can be used instead of the DDA. Both products have FMEDA reports which define the Probability of Failure on Demand and can provide a better degree of protection than the DDA. Additionally, the HIM HART Interface Module has alarming functionality that could also be used with the 1151DP transmitter.

The STA monitors the analog signal and is specifically designed for IEC 61508 applications. It is approved by exida for use in Safety Instrumented Systems (SIS) up to SIL 2 and in redundant architectures (1oo2, 2oo3, etc.) up to SIL 3.

Like the STA, the SPA2 can also monitor the analog signal and provides up to four alarms, a display, and an optional 4-20mA retransmission. The SPA2 is our most popular alarm choice for loops that are not specifically designed in accordance with IEC 61508/61511The HIM monitors the digital component of a HART signal and can be specified with up to two optional relay outputs, which can be configured for signal level alarms or for a number of HART status bits. It can be used to provide diagnostic coverage for a HART transmitter since it monitors the transmitter’s status bits.

Do you want more information? Look up a data sheet to download. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Moore Industries is continually updating our website with new datasheets, user’s manuals, CAD drawings, configuration software and other materials.

Remember that our website is the definitive place to find the most up-to-date product information, so please check here when you need something.

Among the new files currently available on the website is an update to the CPMS Cathodic Protection Monitoring System datasheet to reflect the new GPS Time option. This is an optional method for keeping accurate time when an SNTP (Simple Network Time Protocol) network is not available.

Here are some of the files that have recently been updated on our website:

Datasheets:

CAD Drawings:

Other:

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I need a 4-wire isolator and want to see if your MIT Multi-Channel Signal Isolator will work in my application. I have several 4-wire transmitters where I need to split and isolate the output signal to receivers that are passive (not powered). Will the MIT work provided that I supply 24Vdc power to the unit?

A: The MIT appears to be a perfect fit for your application. MIT’s input is passive, so it is compatible with the active output of a 4-wire transmitter. Because its outputs are active, they are compatible with the passive inputs of the receiver devices. In addition, it uses a universal power input, so it will accept 24Vdc power.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

State regulations required a major pulp and paper company to monitor and record daily effluent water rates. This requirement was being fulfilled by sending an employee from their main control site to a remotely located pond three times a day to manually record water levels. This process was inefficient, time-consuming and didn’t provide them with real-time data.

By installing a system utilizing technology from Moore Industries, the pulp and paper company implemented a system that is scalable for future installations while reducing employee workload and maintaining state regulatory compliance. This process is detailed in a white paper available for download on our website. It highlights how the use of the HCS HART Concentrator System and the NCS NET Concentrator System were critical in helping the company efficiently comply with government regulations.

By installing a system utilizing technology from Moore Industries, the pulp and paper company implemented a system that is scalable for future installations while reducing employee workload and maintaining state regulatory compliance. This process is detailed in a white paper available for download on our website. It highlights how the use of the HCS HART Concentrator System and the NCS NET Concentrator System were critical in helping the company efficiently comply with government regulations.

HART flow level measurements at the pond site were converted to MODBUS RTU by a HCS and sent from a WNM Wireless Network Module at the pond to a receiver radio at the boiler control room. The information was relayed from the wireless radio to an HMI display and DCS/Historian by the NCS. This system enables the company to efficiently get accurate and required readings on the levels in their effluent water system.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

WNIPT: Extracting HART Data from Smart Instruments

According to the FieldComm Group (formerly the HART Communications Foundation), there are more than 30 million HART-enabled instruments installed in chemical and process plants worldwide, and most process transmitters made today are HART compatible. The HART digital signal often contains valuable process measurements and other variables including instrument status, diagnostic data, alarms, calibration values and alert messages.

However, many systems fail to utilize the critical information available from HART-enabled transmitters, valve positioners, flowmeters and other "smart" devices. The February 2015 issue of the Australian magazine What’s New in Process Technology features an article from Moore Industries addressing these concerns. “Extracting HART Data from Smart Instruments” shows how a HART interface device such as our HIM HART Interface Module makes acquiring HART data simple. The data can be sent to a control system via analog signals, discrete outputs or serial communications.

Control Design: Process Skid Standardization

Another recent article highlighting Moore Industries was published by Control Design. In “Process Skid Standardization: What Manufacturers Want,” Dan Herbert discussed an issue common to OEM process skid builders. They keep their costs down when they can deliver the same product to as many customers as possible without customization. However, their clients often have specific needs that they want to be addressed by their process skid.

The article includes feedback by Moore Industries Senior Applications Engineer Jim McConahay, PE, who discussed how our NCS NET Concentrator System can serve as a universal MODBUS I/O interface and eliminate the need for most process skid custom interfaces.

Keep up-to-date with our media coverage at our website.

Check out our HART Gateways, Monitors and Interfaces.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

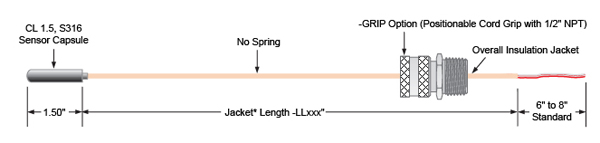

For many temperature applications, getting a high level of accuracy is vital. A white paper from Moore Industries highlights how plant and site engineers can ensure the most accurate temperature measurement for critical applications. Available for download from the Moore Industries website, “A Practical Guide to Improving Temperature Measurement Accuracy” details steps that can also help end users improve the stability of their measurements and reduce calibration costs.

“A Practical Guide to Improving Temperature Measurement Accuracy” shows how to select the best sensor for a particular application and ways to improve the accuracy of the sensor you choose. In particular, it details the reasons why 4-wire RTD sensors are almost always the best choice for high-accuracy temperature applications. Using 4-wire RTD sensors eliminates the errors caused by a copper lead wire. The paper also explains the relationship between classes of sensors (such as Standard and Premium Grade thermocouples and Class A RTDs) and their error rates.

Along with learning how to select sensors, the paper also covers how to reduce errors caused by plant noise, using bath calibration to minimize RTD measurement errors and the relationship between remote I/O and temperature accuracy.

The white paper is written by National Sales Manager Gary Prentice, who graduated with a degree in Electrical Engineering from Lafayette College in Pennsylvania and has 36 years of experience working in the process control industry. He has encountered almost every possible temperature application over his career and is the perfect person to explain the benefits of using 4-wire RTDs.

You can get watch a tutorial on this topic by viewing a Webinar that Gary did a few months ago, which gives even more specific examples of how to improve the accuracy of your temperature measurements.

Moore Industries rep Soltex Chile S.A. recently exhibited at the Exponor 2015 show, which takes place every two years and focuses on the mining industry. It was held in Antofagasta, the main city in northern Chile, which is near the country’s world-class mining operations including copper, gold and nitrates. It’s an important show with plenty of opportunities to connect mining companies with instrumentation solutions.

Soltex’s booth at the show included Fieldbus Device Couplers and Power Supplies from MooreHawke, a division of Moore Industries. These products help to maintain and simplify communications between mining operations and control systems – even in hazardous areas. For example, the TRUNKGUARD Series 200 Fieldbus Device Couplers offer multiple benefits for engineers designing FOUNDATION fieldbus H1 and PROFIBUS PA networks:

- Auto Segment Termination: The patented technology prevents fieldbus segment failure from under- or over-termination, a major problem in fieldbus startups. The TRUNKGUARD's auto-termination feature assures that local parts of a fieldbus segment will continue with proper termination even if remote parts of that segment are accidentally disconnected. This prevents costly downtime and hazardous situations

- Short Circuit Protection: On detection of excess current on a fieldbus spur, the TG200 reacts immediately (20 microseconds) to switch spur current to a nominal trickle-level, rather than limiting the fault current to a fixed (and always higher) level as is typically done by competing units. With removal of the short, the spur is automatically reconnected to the fieldbus segment.

- LED Displays: Diagnostic LEDs positively indicate power status on each fieldbus spur, spur short circuits and the status of auto termination.

To learn more about our Fieldbus solutions, please visit the catalog.

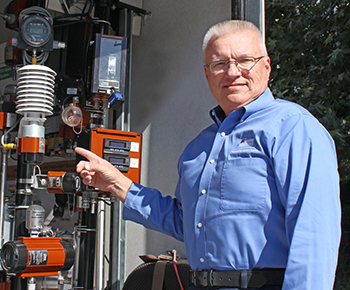

How about this for a ThrowBack Thursday post? One of the photos in our archive shows Mr. Moore at the groundbreaking for Moore Industries’ worldwide headquarters more than 40 years ago. Within six months of the groundbreaking, the company’s first employees had packed up their equipment, loaded it into moving vans and brought it overall in the course of one weekend.

Our building has come a long way from the groundbreaking. Today there are 158 employees here doing everything from manufacturing and engineering new products to handling sales and technical support. A mezzanine was added after the Hawke and Powers acquisitions to address the need for additional manufacturing capacity.

Our building has come a long way from the groundbreaking. Today there are 158 employees here doing everything from manufacturing and engineering new products to handling sales and technical support. A mezzanine was added after the Hawke and Powers acquisitions to address the need for additional manufacturing capacity.

Moore Industries has come a long way in 40 years. Today the company is one of the most recognized and respected names in the world of process instrumentation with millions of units sold and installed in projects all over the world. Part of the reason that Moore Industries has remained so successful is that the company has maintained the same commitment to quality that it had when Mr. Moore founded it in his garage back in 1968. Making sure that customers get solutions to their instrumentation needs is paramount to our philosophy and guides us in the manufacturing and service of our products.

Keep checking in with us for more ThrowBack Thursday posts as we uncover hidden gems from our archive!

Q: I am looking for a differential temperature transmitter. We have used the SPT in the past and know that it will work, but I don’t know if you can use two inputs of two different 4-wire RTDs with the SPT.

A: The SPT has only four input terminals; therefore the number of RTD wires is limited. For differential temperature, one RTD can be a 3-wire and the other RTD can only be a 2-wire. The lead length compensation wire of the 3-wire connection compensates for the lead length of both RTDs. This is only useful if you make sure that all five wires have identical resistance.

To answer your question, you may use two 4-wire RTDs, but you cannot connect all of the wires unless you do it as described above. Wiring details are shown in Figure 17 of the installation manual.

A better option is to use our DIN rail mounted THZ3 HART temperature transmitter, a new model which can accept two three-wire RTDs and provide a differential measurement output. The configuration of the THZ3 is done by utilizing DTMs with PACTware on your PC or by using a HART compatible handheld device or HART host.

Details about the input connections of the THZ3 are in Figure 2.2 of the installation manual.

Model Example: THZ3/PRG/4-20MA/12-42DC [DIN]

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Want to make sure that you don’t miss any of our blog posts, press releases, product news and other company information?

We’re now giving you more ways than ever before to connect with Moore Industries. You can follow us on multiple different social media sites to make sure that you stay up-to-date with everything that is happening with our company by following us at these social media sites:

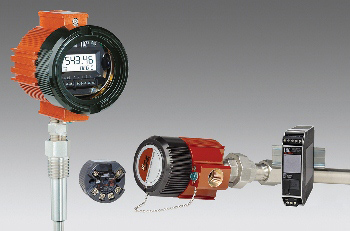

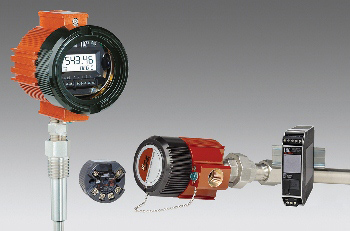

Starting with the THZ3 and TDZ3, Moore Industries introduced a new way for our customers to configure our products.

Starting with the THZ3 and TDZ3, Moore Industries introduced a new way for our customers to configure our products.

The transmitters are both HART and DTM (Device Type Manager) programmable, which means they can be easily programmed and interrogated from anywhere at any time on a 4-20mA loop. This can be done with a standard HART handheld communicator, a HART-compatible host or with any FDT (Field Device Tool)-compliant host or program such as PACTware (available for download at our website) utilizing Moore Industries’ DTM.

At its core, the FDT model creates a unified standard for communications that take place between field devices and host systems. The DTM is the specific software component that contains data, functions and logic elements specific to the device. In the case of the THZ3 and TDZ3, the PACTware software is an interface that provides comprehensively advanced programming capability for thorough transmitter configuration.

One of the main benefits for end users of the FDT technology is that it frees them from constraints caused by being tied to a specific platform or communications method when configuring and monitoring devices. They can choose the best product for their installation and know that it can be easily integrated into their system. A single FDT frame application supports multiple communications protocols such as HART, PROFIBUS, FOUNDATION Fieldbus, DeviceNet, Interbus, AS-Interface and PROFINET IO with other protocols soon to follow.

For more information on the advantages of FDT technology, visit the Technology Benefits page of the FDT Group’s website. You can find additional information on Moore Industries' use of PACTware by reading our recent press release on the subject.

Q: I am interested in an ECA alarm unit, model #: ECA/4-20MA/DH1H1/24DC/DIN. I have three questions:

1. I have a need for three different trip setpoints based on the same transmitter input. How can I accomplish this with the ECAs? Can I use two ECAs using the second ECA with a 1-5VDC input or can the 4-20mA signal be run in series through both ECA inputs?

2. Do I need to specify the -RF option to get the RFI protection? And is the testing for both radiated and conducted susceptibility (RS103, CS114, CS115)? Is it possible to see the test report for the EMI/RFI testing?

3. Is DIN-rail the only mounting option?

A: To answer your three questions:

1. Your 4-20mA signal can be connected in series to the inputs of more than one ECA, each of which with a 50 ohm load on the loop. Alternatively, you can use a SPA2 Limit Alarm Trip (Model #: SPA2/HLPRG/4PRG/U [DIN]) which has four setpoint relay outputs.

2. The ECA-DIN has RFI/EMI Protection to 10V/m, 20-1000MHz for which the trip point would not be affected by more than 0.1% of span. It conforms to the following EMC specifications:

EN50081-2, 1993, Generic Emissions Standard, Industrial Environment.

EN50082-2, 1995, Generic Immunity Standard, Industrial Environment.

EN61010-1, 1995, Safety requirements for electrical equipment for measurement and control use.

3. Both the ECA-DIN and the SPA2 are designed for DIN rail mounting; however, we also offer them with options for flange mounting.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Control Design recently took a look at the current state of remote I/O. Contributing Editor Hank Hogan suggests that remote I/O is becoming “smaller, faster, customizable and intelligent” thanks to innovations within the industry.

The article highlights several examples of companies who have saved money and increased the functionality of their processes by utilizing remote I/O. In one example, an electrical contractor uses automated PLC systems to control construction, excavation and mining machines. In many cases, the machines at the

construction site were a large distance from the main processor – in some cases up to a mile away. This meant using expensive wiring to span the distance and sending a technician on-site if one of the cables failed.

Using remote I/O solves many of these problems. Two locations can be connected via a single twisted wire pair, Ethernet or fiber-optic communication link. Moore Industries offers a wide range of remote I/O solutions including the NCS NET Concentrator System®, which can be used to send just a few – or hundreds – of process signals between the field and a control system whether close by or remote. It’s ideal for creating new monitoring and control networks and also for leaving existing “legacy” sensors, analog instruments and valves in place while taking advantage of digital signal transmission capabilities.

Using remote I/O solves many of these problems. Two locations can be connected via a single twisted wire pair, Ethernet or fiber-optic communication link. Moore Industries offers a wide range of remote I/O solutions including the NCS NET Concentrator System®, which can be used to send just a few – or hundreds – of process signals between the field and a control system whether close by or remote. It’s ideal for creating new monitoring and control networks and also for leaving existing “legacy” sensors, analog instruments and valves in place while taking advantage of digital signal transmission capabilities.

The NCS has several features that make it ideal for plants and remote environments. It offers enhanced RF/EMI protection that eliminates ground loops and protects against the effects of electrical "noise" found in busy plants. It can also be installed in harsh environments with an operating range of -40°C to +85°C (-40°F to +185°F).

For more information about the use of the use of Distributed I/O in plant settings, please download our "Peer-to-Peer Distributed I/O Systems Solve Signal Interface Problems" white paper.

Another option available for connecting field instruments to control systems is to use wireless I/O. This method completely eliminates the need for wiring, makes it easy to expand a network and allows for the transmission of signals across large distances.

The WNM Wireless Network Module from Moore Industries can be used in conjunction with the NCS to communicate with just one – or multiple – WNM modules configured as Remote modules in a Point-to-Point system. In a Point-to-Multipoint architecture, modules can be configured as repeaters to relay signals when a direct line of sight does not exist between a Master and Remote modules, or to significantly extend the transmission distance allowable within a WNM network.

The WNM Wireless Network Module from Moore Industries can be used in conjunction with the NCS to communicate with just one – or multiple – WNM modules configured as Remote modules in a Point-to-Point system. In a Point-to-Multipoint architecture, modules can be configured as repeaters to relay signals when a direct line of sight does not exist between a Master and Remote modules, or to significantly extend the transmission distance allowable within a WNM network.

Find more information about Moore Industries' complete line of remote I/O products by downloading our line card.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have been using Moore Industries DCA series switches for some time. Is there a like-for-like digital microprocessor-based replacement available?

A: The SPA2 series is a microprocessor-based design with all of the capabilities of nearly any permutation of the DCA. It does have a different form and fit, so we will need to know the complete model number of your DCA unit in order to recommend a SPA2 model.

The most common type of DCA mounts to a back panel with four screws, such as model DCA/4-20MA/DH1L1/117AC [UB]. We can provide the SPA2 with the same mounting bracket so that it fits the same footprint and hole pattern.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am monitoring up to 13600 Hz from a magnetic pickup on a gas turbine for speed indication and would like to use the FDY Frequency-to-DC Converter. Are either the PRG input or the 10-250V input handle this frequency?

A: Both input options can handle this frequency.

Normally the PRG input is correct for magnetic pickups. Some of them will put out a pulse voltage above the FDY's max of 30VAC, but it can be lowered by moving the pickup farther from the target. Use the FDY/10-250AC if you know for sure that the voltage pulse will be above the FDY/PRG’s upper limit. However, with this model, the pulse must be at least 10VAC.

Please note that the FDY with the 10-250AC input is not available with I.S. approval.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I have a question about the ECA-DIN Current and Voltage Alarm with the DH1L1 (Dual, High/Low, Failsafe) output option. The literature for the product says that "the failsafe relays are de-energized in an alarm condition or during power loss to the unit." Is this statement also true if there is a loss of input signal such as a broken wire?

Q: I have a question about the ECA-DIN Current and Voltage Alarm with the DH1L1 (Dual, High/Low, Failsafe) output option. The literature for the product says that "the failsafe relays are de-energized in an alarm condition or during power loss to the unit." Is this statement also true if there is a loss of input signal such as a broken wire?

A: The Failsafe setting means that the relay coils are de-energized in the alarm state. Naturally, if power is lost they will be de-energized. In case of loss of signal, the ECA will perceive the condition as a low signal and behave accordingly. That is, if you have a low alarm setting, the alarm will be activated. If you have a high alarm set, it will not be activated.

If you need more functionality such as being able to discern between a low signal and a lost signal, we recommend the SPA2. Unlike the ECA, it is a microprocessor-based design. This means that it can be configured for a variety of alarm and input signal conditions.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

We know it is easier for many customers to communicate using MODBUS RTU protocol than HART protocol and that makes the HCS HART® Concentrator System a very popular tool.

We also know customers want more diagnostic information so they can access the health of their processes and instrumentation. HART Command 48 is what the industry and the HCS uses to retrieve diagnostic information from the HART slave device, whether that is a transmitter or a valve positioner. The HCS will not implement Command 48 unless you turn on that feature by checking “Acquire Additional Status” on the HART tab of the configuration software.

We also know customers want more diagnostic information so they can access the health of their processes and instrumentation. HART Command 48 is what the industry and the HCS uses to retrieve diagnostic information from the HART slave device, whether that is a transmitter or a valve positioner. The HCS will not implement Command 48 unless you turn on that feature by checking “Acquire Additional Status” on the HART tab of the configuration software.

Once enabled, if your HCS has firmware version 4 or earlier, the HCS retrieves Status bytes 0 through 5 and populates the diagnostic data into MODBUS registers. With 6 bytes by 8 bits each that is 48 pieces of information. Should you be using one of our newer HCS with firmware version 5 or higher, we pull 25 bytes or 200 bits of diagnostic data and allow it to be read by the MODBUS master.

Of course, the specific diagnostic information is under the control of the manufacturer of the transmitter or positioner, but the HCS makes it easily readable.

Are you or your customers taking advantage of this powerful tool?

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

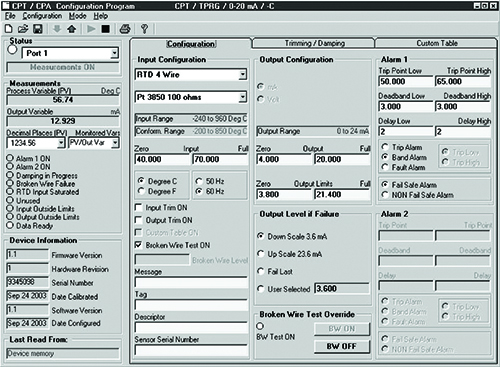

Last month we told you about a new video tutorial on the configuration of the THZ3 and TDZ3. We’ve now updated our YouTube page with video tutorials from Customer Service Director Bob Croughwell on how to use the included software to configure several of our most popular products:

•STA Safety Trip Alarm (TPRG and HLPRG models)

•SPA2 Limit Alarm Trips (TPRG and HLPRG models)

•HCS HART Concentrator System

There is a video playlist for each product with several videos showing the steps you can take to program and monitor individual features for each product. Along with an overview of the configuration software, some of the feature-specific tutorial videos include information about:

•HART and HART Devices

•MODBUS

•Status

•Alarms

•Analog Inputs/Outputs

•Custom Curves

•Display

•Scaling