In Part 2 of our Understanding Signal Isolators, Converters, and Interfaces series, we explain the key differences between 4-wire (line-powered) isolators and 2-wire (loop-powered) isolators used in industrial process control. Learn how signal isolator power architecture impacts accuracy, reliability, load capability, and installation, including support for 4–20 mA loops, voltage outputs, bipolar signals, and long cable runs. This video covers ground loops, signal isolation, loop power limitations, and how to choose the right isolator for real-world applications in automation, instrumentation, and control systems.

Watch Part 1: Basics of Signal Isolation

Learn more about Moore Industries Signal Isolation and Conversion Solutions here.

In Part 1 of Understanding Signal Isolators, Converters, and Interfaces, we explore the fundamentals of signal isolation, how it works, why it matters, and how it protects your process systems. Learn how isolators break galvanic paths to eliminate ground loops, prevent electrical interference, and keep measurements stable and reliable. We’ll cover real-world challenges like ground loops, explain how optical and transformer isolation methods provide protection, and clarify the difference between two-way and three-way isolation. Whether you’re new to process control or looking to deepen your instrumentation knowledge, this video lays the groundwork for understanding accurate, safe, and interference-free signal measurement.

Learn more about Moore Industries Signal Isolation and Conversion Solutions here.

Discover Moore Industries’ Signal Isolators, Repeaters, Converters, and Splitters—designed to protect your process and keep measurements accurate. From SIL 3-capable SSX and SST Safety Isolators to HIX/HIT HART Isolators, ECT-DIN models, SIY PC-programmable units, miniMOORE multi-channel isolators, and the flexible FCT, we have the right solution for every application. Our isolators stop ground loops, eliminate noise, split and boost signals, and ensure safe integration with indicators, BPCSs, PLCs, SCADA, and Asset Management Systems. Rugged, reliable, and built for long-term stability, Moore Industries Signal Isolators deliver trusted performance, protect critical loops, and keep your systems running smoothly—even in the most demanding industrial environments.

Learn more about Moore Industries Signal Isolation and Conversion Solutions here.

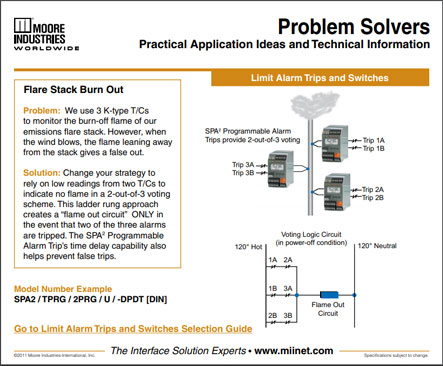

In Part 7 of “Understanding Alarm Trips,” we explore how redundant architectures and voting strategies help prevent nuisance trips and increase process reliability. You’ll learn why relying on a single alarm trip can fall short in critical processes, and how using multiple sensors with schemes like one-out-of-two, two-out-of-two, or two-out-of-three improves safety, filters out false alarms, and avoids costly downtime. Real-world examples, such as flare stack monitoring in refineries and gas plants, demonstrate how redundancy not only enhances protection but also improves process availability, reduces maintenance demands, and facilitates smoother plant operations.

Watch Part 1: Moore Industries Alarm Solutions for Process Safety

Watch Part 2: "Hard" vs. "Soft" Alarms

Watch Part 3: Types of Alarms

Watch Part 4: Alarm Trip Relay Responses

Watch Part 5: More Alarm Trip Relay Responses

Watch Part 6: Intrinsically Safe Associated Apparatus Alarm Trips

Learn more about Moore Industries Alarm Trip Solutions here.

In Part 6 of “Understanding Alarm Trips,” we explore how alarm trips can be applied in hazardous locations where Intrinsic Safety (IS) is the method of protection. This video introduces the SPA2IS Intrinsically Safe Alarm Trip from Moore Industries, showing how it can simplify IS installations by acting as an associated apparatus. You’ll learn how traditional IS systems use separate Zener Diode barriers or Isolated barriers to limit energy and prevent ignition, and why those solutions often add cost, complexity, and grounding challenges. We’ll explain how the SPA2IS integrates the barrier directly into the alarm trip, reducing wiring, cabinet space, grounding needs, and installation costs, all while maintaining safety compliance. By understanding how associated apparatuses work, you’ll see how the SPA2IS can streamline your hazardous area alarming and lower the total cost of ownership without compromising safety.

Watch Part 1: Moore Industries Alarm Solutions for Process Safety

Watch Part 2: "Hard" vs. "Soft" Alarms

Watch Part 3: Types of Alarms

Watch Part 4: Alarm Trip Relay Responses

Watch Part 5: More Alarm Trip Relay Responses

Learn more about Moore Industries Alarm Trip Solutions here.

In Part 5 of “Understanding Alarm Trips”, we build on the basics of relay responses and explore the advanced settings that make alarms more reliable and precise. This video covers how failsafe and non-failsafe operation impacts safety-critical applications, and how those modes work with Normally Open and Normally Closed contacts to fine-tune your alarm logic. We’ll also explain why deadband is essential to prevent relay chatter, when to use latching alarms for operator acknowledgment, and how to select the right contact rating to protect your relays from overload. Finally, we look at time delay features, showing how they help filter out nuisance alarms and false trips caused by brief signal spikes. By understanding these features, you’ll see how alarm trips can do more than just switch on and off, they can be configured for dependable, accurate responses that keep your process running safely.

Watch Part 1: Moore Industries Alarm Solutions for Process Safety

Watch Part 2: "Hard" vs. "Soft" Alarms

Watch Part 3: Types of Alarms

Watch Part 4: Alarm Trip Relay Responses

Learn more about Moore Industries Alarm Trip Solutions here.

In Part 4 of "Understanding Alarm Trips", we move from alarm types to the mechanics of how those alarms take action. This video breaks down the fundamentals of relay responses, covering the difference between Normally Open (NO) and Normally Closed (NC) contacts, and why this choice matters in designing your alarm logic. We’ll also explore the most common relay configurations, Single-Pole/Single-Throw (SPST), Single-Pole/Double-Throw (SPDT), and Double-Pole/Double-Throw (DPDT)—showing how each works, when to use them, and how they can trigger anything from a simple indicator light to a multi-step safety shutdown. By understanding these contact types and relay setups, you can match your alarm trip’s physical response to your exact process needs, ensuring reliable performance when it matters most.

Watch Part 1: Moore Industries Alarm Solutions for Process Safety

Watch Part 2: "Hard" vs. "Soft" Alarms

Watch Part 3: Types of Alarms

Learn more about Moore Industries Alarm Trip Solutions here.

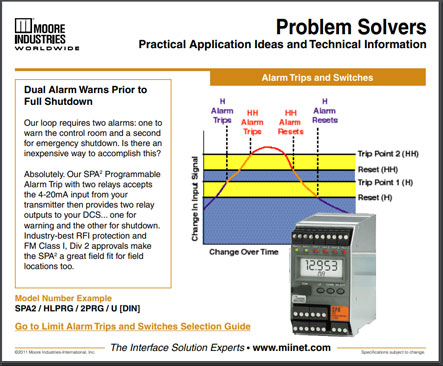

In Part 3 of "Understanding Alarm Trips", we explore the wide range of alarm types available in industrial safety and control systems. From standard High and Low alarms to more advanced functions like High/High, Low/Low, Rate-of-Change, and Stuck Input detection, this video shows how each configuration plays a role in building safer, smarter processes. You’ll also see how multiple relay outputs allow for layered warnings and shutdown action, helping you tailor alarm strategies to fit your unique application. Whether you're detecting simple threshold breaches or complex failure conditions, understanding your alarm options is key to reliable protection.

Watch Part 1: Moore Industries Alarm Solutions for Process Safety

Watch Part 2: "Hard" vs. "Soft" Alarms

Learn more about Moore Industries Alarm Trip Solutions here.

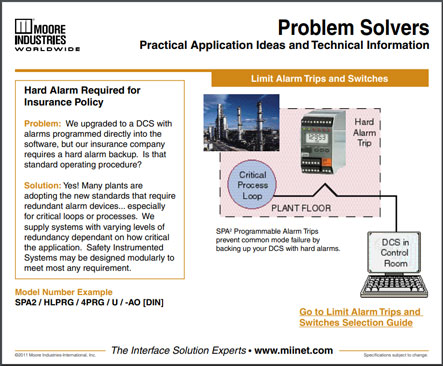

In Part 2 of "Understanding Alarm Trips", we take a closer look at the differences between “hard” and “soft” alarms in industrial safety and control systems. You’ll learn how hard-wired alarms provide independent, real-time protection—even when PLCs or BPCS systems fail—and why they are often used in Safety Instrumented Systems (SIS) for critical redundancy. We also explore how hard alarms support compliance with Functional Safety standards like IEC 61508 and IEC 61511, and the key benefits they offer in fast-moving or hazardous process environments.

Watch Part 1: Moore Industries Alarm Solutions for Process Safety

Learn more about Moore Industries Alarm Trip Solutions here.

In Part 1 of our Alarm Trips Series, discover how Moore Industries’ Alarm Trip Solutions deliver reliable protection and process safety when it matters most. Designed for critical industrial applications, we offer alarms that are SIL 2/3 capable, exida-certified for functional safety, and available in PC- or site-programmable models. From compact single-channel alarms to powerful multiloop logic solvers, our solutions monitor current, voltage, temperature, and more, triggering fast, decisive action when conditions exceed safe limits. Built to perform in hazardous areas and harsh environments, they offer isolated channels, flexible outputs, and long-term durability.

Learn more about Moore Industries Alarm Trip Solutions here.

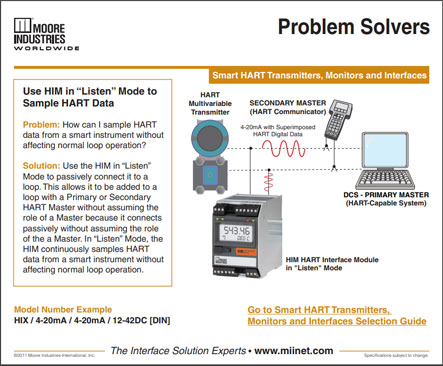

HART-enabled field devices offer far more than just a 4–20mA signal, but in many facilities, their full diagnostic and configuration potential goes unused. Moore Industries’ HES HART to Ethernet Gateway System with HART Tunneling makes it easy to bridge that gap, delivering full remote access to connected HART devices over standard Ethernet networks.

HART-enabled field devices offer far more than just a 4–20mA signal, but in many facilities, their full diagnostic and configuration potential goes unused. Moore Industries’ HES HART to Ethernet Gateway System with HART Tunneling makes it easy to bridge that gap, delivering full remote access to connected HART devices over standard Ethernet networks.

With HART Tunneling, maintenance and asset management tools like PACTware and valve management systems can communicate directly with up to 16 HART field devices as if they were connected locally. This transparent, bi-directional connection allows technicians to configure, calibrate, and troubleshoot devices without needing handheld communicators or field access, dramatically reducing downtime and labor, especially in hard-to-reach or hazardous locations.

The HES integrates easily into existing systems without costly upgrades. It also features a built-in web server for easy read-only monitoring from any browser. Whether you’re supporting predictive maintenance or improving commissioning workflows, the HES makes smarter device access simple.

Read the full whitepaper to learn how HART Tunneling with the HES Gateway System can help your facility maximize the value of their HART instruments.

At Moore Industries, we’re excited to announce that our SLA Multiloop and Multifunctional Safety Logic Solver and Alarm has earned Factory Mutual (FM) approval as a Non-Incendive instrument. This certification allows the SLA to operate in Class I, Division 2, Groups A, B, C, and D Hazardous locations in the United States and Canada, making it a reliable safety shutdown choice for environments with potentially explosive gases, vapors, dust, or fibers.

At Moore Industries, we’re excited to announce that our SLA Multiloop and Multifunctional Safety Logic Solver and Alarm has earned Factory Mutual (FM) approval as a Non-Incendive instrument. This certification allows the SLA to operate in Class I, Division 2, Groups A, B, C, and D Hazardous locations in the United States and Canada, making it a reliable safety shutdown choice for environments with potentially explosive gases, vapors, dust, or fibers.

Part of our FS Functional Safety Series, the SLA is built to excel in safety-critical applications. With FM approval, it’s now cleared for use in both General (safe) and Hazardous Locations, serving industries like oil and gas refining, offshore rigs, and chemical and pharmaceutical plants.

Why Choose The SLA?

The SLA bridges the gap between single-loop logic solvers and costly safety PLCs, offering:

- Advanced Alarming and Logic: With up to 16 alarms and voting logic, the SLA provides tailored solutions for your Safety Instrumented Functions (SIF).

- User-Friendly Setup: Intuitive configuration through drop-down menus, checkboxes, and Excel-like equations.

- Seamless Integration: Supports MODBUS/TCP, MODBUS RTU, and HART pass-thru for easy system integration.

- Exida Certified: for use in Safety Instrumented Systems (SIS) and SIL 2/3 capable.

Built for Tough Environments

With FM approval, the SLA is ideal for industries where safety is critical, including:

- Oil and Gas: Ensuring safe operation in refining, extraction, and transport.

- Offshore Rigs: Reliable performance in harsh conditions.

- Chemical Plants: Precision and safety in flammable atmospheres.

The SLA’s FM approval reinforces its reliability in hazardous areas. Learn Moore about the SLA to enhance safety and efficiency in your processes here.

Discover Moore Industries' Temperature Solutions, which deliver precision, reliability, and versatility for your temperature measurement and control needs. Our comprehensive product line includes HART, Dual Input, PC-Programmable Transmitters with or without Displays, Functional Safety exida certification, MODBUS, 2- and 4-wire options, and Universal Input Temperature Transmitters accepting inputs from Current, Voltage, RTDs, Thermocouples, or Resistance. From ready-to-install temperature assemblies with Sensors, Thermowells, Fittings, Connection Heads, and Enclosures, including explosion-proof and flameproof designs to the innovative Worm Flexible Temperature Sensors, we provide solutions that meet the demands of any process environment. Engineered for accuracy and durability, our temperature solutions simplify installation, reduce maintenance, and ensure optimal performance in even the most challenging conditions.

Learn more about Moore Industries Temperature Solutions here.

Discover Moore Industries' Functional Safety Solutions, designed to provide unparalleled reliability and risk reduction for your process. The FS Functional Safety Series offers a comprehensive product line, purpose-built to integrate seamlessly into your Safety Instrumented System (SIS). With full third-party certification to IEC 61508, these SIL 2 and SIL 3 capable instruments eliminate the need for proven-in-use justification, saving time and resources. Engineered to perform in even the most challenging environments, they operate within a broad temperature range of -40 to 85°C, delivering the protection you can count on when it matters most.

Learn Moore About our Fucntional Safety Solutions Here.

In a metals refinery, precise acid concentration management is critical to ensuring that various processes such as leaching and metal extraction go smoothly and efficiently. An imbalance, particularly as it relates to acid levels, can result in decreased productivity, product quality difficulties, equipment damage, and even personnel danger.

In this application, to mitigate high-risk conditions due to out-of-specification acid concentration levels, a Safety Integrity Level 2 (SIL 2) Safety Instrumented Function (SIF) is implemented using the SLA Safety Logic Solver and Alarm. Redundant flow and acid concentration transmitters are monitored by the SLA, along with the status of acid pumps and demineralized shutoff valves. To ensure proper safety coverage, continuous monitoring of several variables and advanced alarming and logic is required.

The SLA has several inputs and 16 internal alarms which can be configured to monitor flow and acid concentration levels from the redundant transmitters. Additionally, a total of six digital inputs are fed into the SLA which report acid pump run status and demineralized water shutoff valve status. The SLA’s internal alarm statuses or outputs, along with the digital inputs, are then used to create internal logic equations using simple to configure Excel-like formulas to generate more advanced alarm scenarios. The SLA then uses these advanced internal alarms to create a 1oo2 voting logic strategy to determine when it is necessary to trigger the shutoff valves via its relay outputs. In addition, all inputs, outputs and internal variables and alarms can be monitored via the SLA’s read only web server or communicated to a remote host by MODBUS/TCP or MODBUS RTU.

Key attributes:

- 16 internal alarms and 16 internal logic equations aid in advanced shutdown strategy

- Simple to configure 1oo2 voting alarm logic with check boxes and pill-down menus

- SLA is SIL 2/3 capable and exida® approved to IEC 61508:2010 standard

- Accepts six Digital Inputs to monitor pump run status and open/closed status of valves

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

Temperature monitoring is essential for maintaining optimal performance and safety in industrial processes. Traditional systems using individual sensors and transmitters often become costly and complicated, especially in environments with numerous monitoring points. High-density temperature monitoring systems leveraging Ethernet connectivity offer a more efficient and cost-effective alternative. This whitepaper covers the advantages of these Ethernet-based systems, highlighting the TCS Temperature Concentrator System used with the HES HART-to-Ethernet Gateway System, which significantly enhances data transmission speeds, operational efficiency, while reducing costs and complexity.

Temperature monitoring is essential for maintaining optimal performance and safety in industrial processes. Traditional systems using individual sensors and transmitters often become costly and complicated, especially in environments with numerous monitoring points. High-density temperature monitoring systems leveraging Ethernet connectivity offer a more efficient and cost-effective alternative. This whitepaper covers the advantages of these Ethernet-based systems, highlighting the TCS Temperature Concentrator System used with the HES HART-to-Ethernet Gateway System, which significantly enhances data transmission speeds, operational efficiency, while reducing costs and complexity.

Traditional temperature monitoring systems face numerous challenges, including complex wiring, high installation costs, and extensive maintenance requirements. Each temperature sensor requires a dedicated transmitter, leading to a tangled mess of cables and high equipment costs. These systems also demand significant labor for installation and maintenance, further driving up expenses. The TCS Temperature Concentrator System addresses these issues by consolidating multiple sensor signals into a single data stream, reducing the number of instruments and wiring needed. This streamlined approach not only cuts costs but also simplifies installation and maintenance.

The incorporation of Ethernet-based monitoring systems offers significant advantages over traditional methods. By utilizing existing Ethernet infrastructure, these systems minimize wiring, reduce installation and maintenance costs, and improve data transmission speeds. The TCS Temperature Concentrator System, when paired with the HES HART-to-Ethernet Gateway, demonstrates these benefits. With the capacity to connect to up to 128 temperature points, this system provides unparalleled scalability and flexibility, making it an ideal solution for facilities seeking to enhance their temperature monitoring capabilities.

For a more detailed exploration of the benefits and implementation of high-density temperature monitoring systems, read the full whitepaper here.

Temperature is the most widely monitored process variable for industrial facilities. Whether these temperature measurements are utilized for control or supervisory purposes, gathering dozens or even hundreds of points is not only costly but technically challenging too. When you are faced with this requirement consider the TCS Temperature Concentrator System. The TCS consists of one or more 16 channel TCM Temperature Concentrator Modules where each channel can be configured for Thermocouple, RTD, Potentiometer, ohms or millivolt inputs, and then outputs those readings via HART protocol. Once configured, up to eight TCMs can be connected to a HES HART-to-Ethernet System so you can send up to 128 temperature signals over your high-speed Ethernet backbone to your monitoring or control system.

The HES utilizes a device-specific HART command enabling it to gather all 16 temperature readings in one message, in less than one second. The HES supports MODBUS/TCP and HART-IP industrial protocols and includes a built-in web server so even an off-the-shelf web browser like Chrome or Microsoft Edge can be used to view or monitor your temperature points. The TCM is intrinsically safe and approved for use in hazardous areas.

Key Attributes:

• Up to eight TCMs can be connected to each HES

• Each HES supports 128 points of temperature monitoring over Ethernet

• TCM is intrinsically safe approved for use in hazardous areas

• The HES utilizes a HART device specific command for high speed monitoring

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or use our online form.

Large semiconductor and microelectronic facilities have many process loops where a bank of displays or panel meters are needed for installation in control rooms or in remote cabinets.

![]()

When a panel meter display is required, consider the Nema 4X UL approved 330R2 1/8 DIN Process & Temperature Meter and Alarm. The 330R2 has a large 4 digit bright LED display and accepts T/Cs, RTDs, mA, and V inputs. The unit accepts two types of input power ranges: Low Level ACDC 12-24VAC/12-36VDC; or High Level ACDC 85-265VAC/90-265VDC .and can be field-programmed via the front push buttons or is PC-Programmable with free software. The 330R2 comes standard with two SPDT alarms and has an isolated analog output that can be ordered as an option. The High Level ACDC powered units include a –TX (Transmitter Excitation) option to power a connected transmitter. In addition, the display has an adjustable intensity setting which is especially useful when installed in direct sunlight.

The 330R2 can also be used as a low-cost pump controller when combined with a continuous-level transmitter. This allows it to be utilized for one of the most common pump control applications, controlling and alternating two pumps.

Key Attributes:

- Push button or PC-Programmable

- Nema 4X and UV resistant, bright 4-digit LED display with adjustable intensity setting

- Two SPDT alarm contacts included as standard

- Pump controller feature for controlling and alternating two pumps

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form

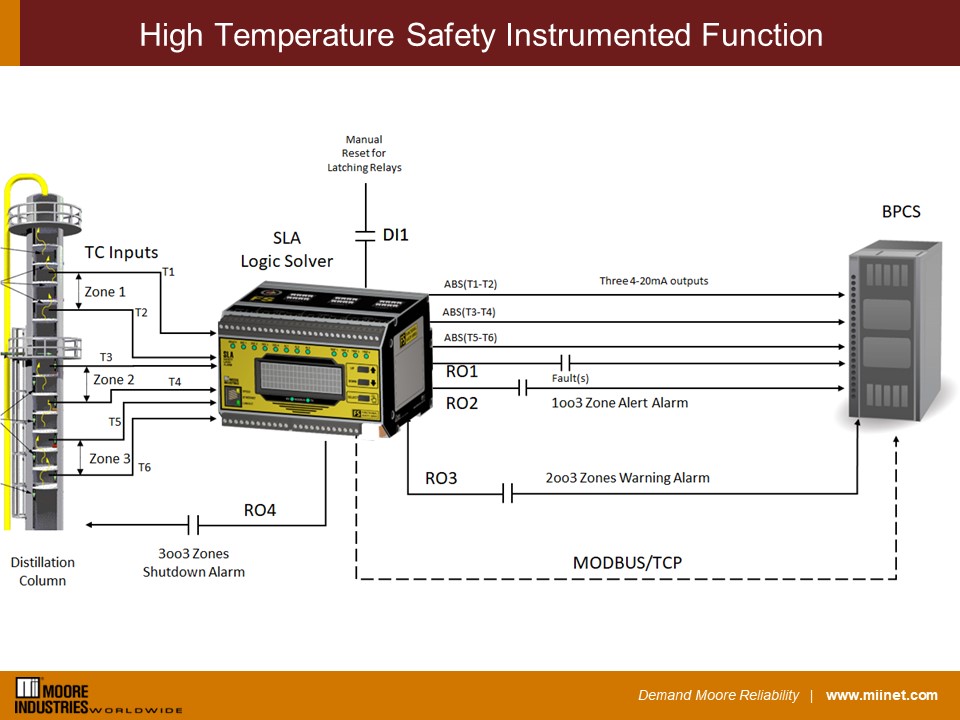

Temperature stratification is normal in distillation columns. However, in some chemical or refinery processes too much temperature differential between layers within the column can yield poor quality product or create a dangerous condition that could lead to a column rupture or explosion.

The SLA can help mitigate this situation by accepting up to six temperature inputs, in this case thermocouples, and performing an absolute differential calculation between any temperature sections to ensure that temperature stratification levels within critical zones in each column never differ by too much. The SLA can implement up to 16 alarms based on any input, equation, or combination of inputs/equations. This Figure shows the SLA installed in a temperature alarm Safety Instrumented System (SIS) application.

In this application, three separate alarms, one for each zone, are configured to alarm if more than a 50degC temperature differential exists between the zone’s lower and upper temperature points. The temperature differential for each zone is calculated with an absolute differential equation via SLA’s advanced configuration settings. An alarm voting architecture is put in place where relay outputs will be activated to trigger an alert (1oo3 voting), warning (2oo3 voting), or shutdown (3oo3 voting) situation. A contact closure wired to one of the SLA’s four available Discrete I/O channels is used to release latching alarms and/or relays.

The BPCS (Basic Process Control System) monitors each zone’s temperature differential via the SLA’s three analog outputs. All inputs, outputs, alarms, faults, and various other parameters from the SLA are transmitted via MODBUS/TCP over Ethernet to the BPCS.

The SLA’s built-in web server also provides quick and easy read-only viewing of inputs, alarms, outputs, internal variables, faults, warnings, and more via any standard web browser. Prebuilt web pages include simple to navigate menus and tables that neatly lay out all of the SLA’s parameters.

Key attributes:

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- Easy to use equation editor allows for quick absolute value temperature calculations

- Voting architecture alarms of 1oo3, 2oo3 and 3oo3 simple to configure with checkboxes

- -40 to 85 degrees Celsius ambient temperature operating range

- Standard MODBUS/TCP protocol sends all process and diagnostic data to BPCS

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

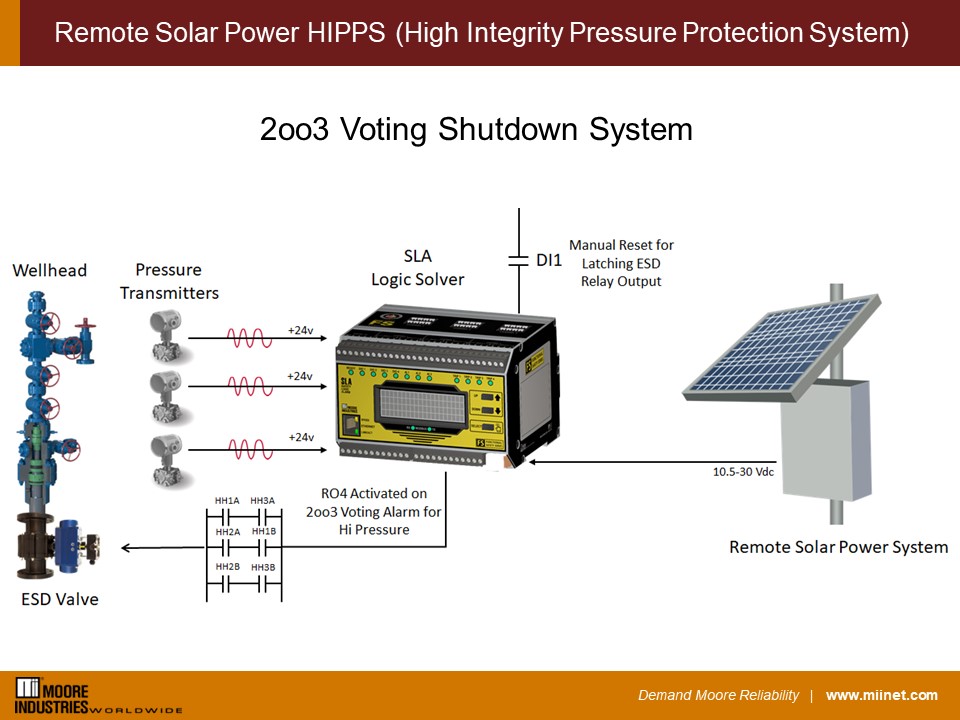

Upstream gas wellheads can experience extremely high pressure and surges. To protect personnel and equipment, wellhead casing pressure is often monitored in case there is a situation where the wellhead needs to be shut down. Traditionally simple pressure switches were used, but today companies are required to implement proper safety systems. In addition, upstream gas wellheads often reside in remote locations where access to electricity and harsh conditions propose significant challenges. Moore Industries SLA Safety Logic Solver and Alarm offers an effective and reliable solution for these applications due to its unique set of characteristics, which include exida® IEC61508 approvals, built-in voting logic, rugged housing, ability to run off 10.5-30Vdc power, and built to withstand ambient temperatures that have an operation range from -40 to 85 degrees Celsius.

In the above gas wellhead application, three separate smart HART pressure transmitters are wired to the SLA (HART data from the pressure transmitters can also be passed thru to the SLA’s three optional analog outputs when required). With its built-in voting logic capability, the SLA performs a 2oo3 safety voting architecture to shut down the well when dangerous conditions exist. The SLA’s built in loop power supply on each of its three channels provides operating power to all three pressure transmitters. The SLA has up to four digital I/O channels that can be configured as inputs or outputs. In this application,n one of the digital inputs is configured to reset the latching ESD Valve relay output but could be utilized to reset any of the SLA’s 16 internal alarms or other SLA relay outputs. Finally, due to the remote nature of this application, the SLA is powered by 10.5-30Vdc generated through a remote solar power system.

Key attributes:

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- Requires only one instrument for voting applications with built-in voting logic capability

- Meets 10.5-30Vdc power requirement for solar or battery backup systems

- -40 to 85 degrees Celsius ambient temperature operating range

- Rugged aluminum casing which helps dissipate heat and provides protection against radio frequency and electromagnetic noise in harsh environments.

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

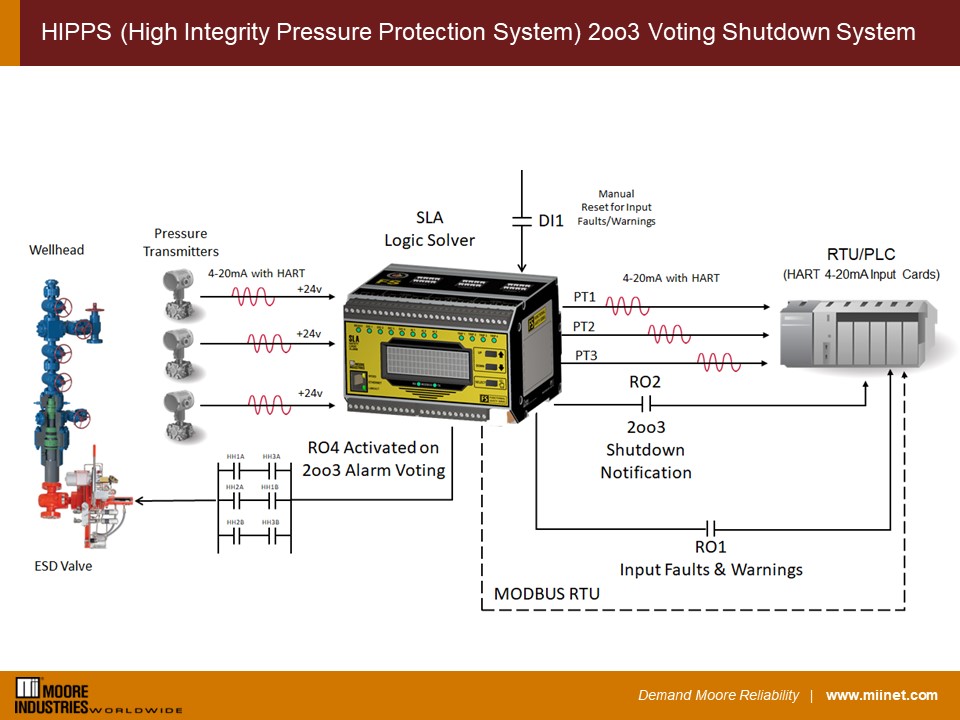

Upstream gas wellheads can experience extremely high pressure and surges. In order to protect personnel and equipment, wellhead casing pressure is often monitored in case there is a situation where the wellhead needs to be shutdown. Traditionally simple pressure switches were used but today companies are required to implement proper safety systems. Figure 13.1 shows the SLA installed in a remote oil and gas wellhead application using 2oo3 voting logic to ensure pressure protection.

In this application, to protect personnel and the process from high pressure spikes, the three separate pressure transmitters are wired to the SLA where it can perform a 2oo3 safety voting architecture to shut down the well when dangerous conditions exist. The SLA’s built in loop power supply on each of its three channels provides operating power to all three smart HART pressure transmitters. The HART signal from the three pressure transmitters is passed-through to each of the SLA’s corresponding analog outputs so the RTU/PLC has direct access to all HART programming, variables, and diagnostics of each connected transmitter.

The retransmission of these three pressure transmitters by the SLA, versus wiring in series with the RTU/PLC input cards, provides higher availability to the safety function since a catastrophic failure in the analog input cards or the RTU/PLC itself doesn’t affect the 2oo3 logic shutdown function of the SLA.

Additional relay outputs of the SLA also keep the RTU/PLC informed of shutdown status and any input faults experienced by the SLA. A digital contact input allows any alarm or relay configured as latching to be manually reset. Finally, all inputs, outputs, internal equations, variables, alarms, relay status and more are digitally transmitted to the RTU/PLC via a read-only MODBUS RTU signal.

Key attributes:

- Simple to configure 2oo3 voting alarm with check boxes and pull-down menus

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- HART pass-through of pressure transmitter diagnostics to RTU/PLC

- SLA provides 24Vdc power to all three pressure transmitters for ease of wiring

- -40 to 85 degrees Celsius ambient temperature operating range

- Standard MODBUS RTU protocol sends all process and diagnostic data to RTU/PLC

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

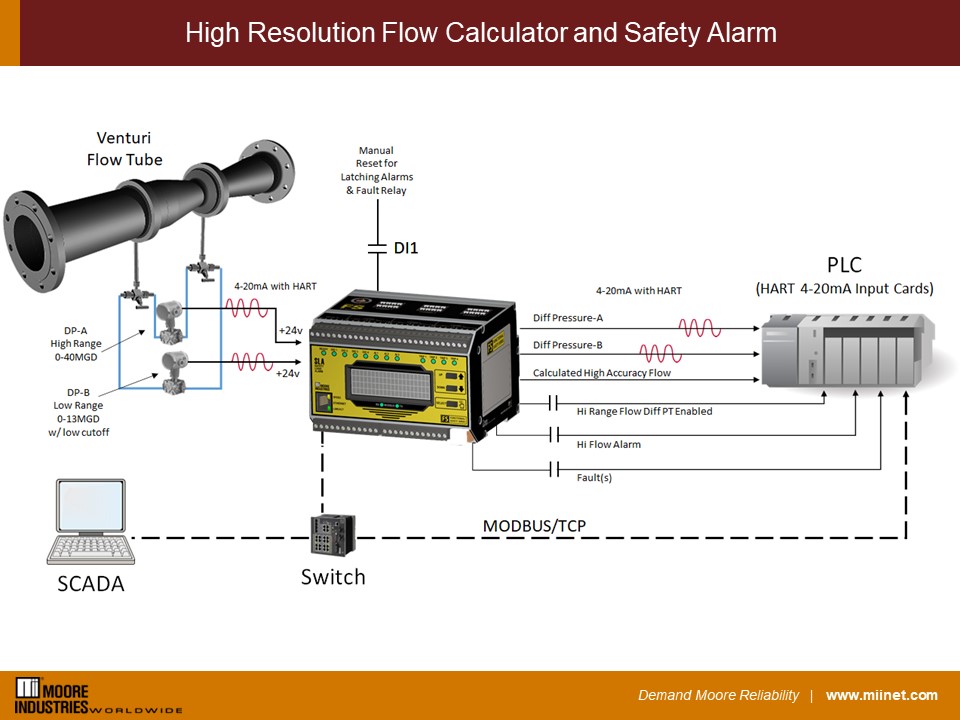

Plants that have large fluctuations in flow demand, like potable water plants, often need large flow capacity measuring devices that don’t create large pressure reductions. Venturi tubes are good for these applications, but often if the flow span is large, consistent accuracy across the entire flow range is difficult to achieve. One way to alleviate this is to use double stacked differential pressure transmitters where one DP transmitter is ranged for lower flow rates while the other handles higher flow rates. With this type of configuration, there needs to be some type of smart device involved to automatically switch between transmitters to achieve the best flow accuracy results.

The SLA Safety Logic Alarm provides this decision-making capability and the safety layer of protection needed to alert the plant when demand has reached very high levels. While safety PLCs can accomplish such tasks, there may be a number of reasons why it is not convenient: cost, remote locations, difficulty of programming, or simply that the PLC has no spare memory capacity. This figure shows the SLA installed as a high-resolution flow calculator and safety alarm.

This application includes two differential pressure transmitters connected to the pressure ports of a venturi tube, ranged 0-13 million gallons/day and 0-40 million gallons/day for low and high flow rates respectively. Each of the smart HART differential pressure transmitters is powered by the SLA and their HART signals are passed through to PLC input cards. The SLA primarily serves as a safety logic alarm to notify the PLC when extremely high-demand situations occur.

Additionally, the PLC and SCADA system need to monitor accurate flow rates from the venturi tube. To ensure that the 4-20mA flow signal, and the MODBUS registers also representing the flow rate are as accurate as possible, the SLA is programmed to switch between the differential pressure transmitters, depending on current flow rates. The flow rates are calculated with a differential pressure flow equation via SLA’s advanced configuration settings. When flow reaches a rate of 12.9MGD, the SLA automatically switches to the higher-ranged DP transmitter and automatically switches back to the lower-ranged DP transmitter when flow falls below 12.9MGD. This assures maximum flow rate accuracy across the entire flow rate span.

The SLA also retransmits each of the DP transmitter signals back to the PLC and provides relay outputs when the flow rate exceeds 39MGD, the high-range DP transmitter is selected, or when there are system or input faults captured by the SLA. A digital contact input allows any latched alarms or relays to be cleared. The SCADA system and PLC receive all inputs, outputs, internal equations, variables, alarms, relay status and more via the MODBUS/TCP read-only signal.

Key attributes:

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- -40 to 85 degrees Celsisus ambient temperature operating range

- Simple to configure logic for flow range selection for high-resolution flow calculation

- HART pass-through of pressure transmitter diagnostics to PLC & SCADA system

- Standard MODBUS/TCP protocol sends all process and diagnostic data to PLC

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

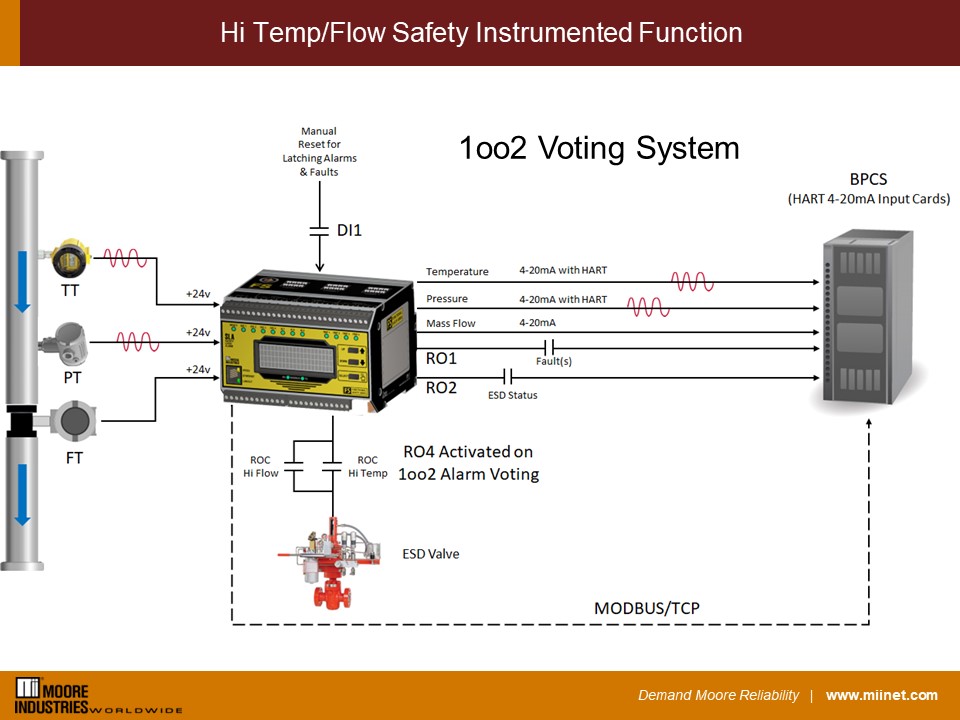

Many critical processes require that flow rates are closely monitored for both product quality and safety. Some of these processes are remotely located in a facility from the BPCS (Basic Process Control System). When calculations like mass flow are required for safety considerations, this can sometimes add precious decision-making time to an already burdened BPCS. With the SLA’s built-in equation editor, calculations can be done remotely and oftentimes faster so process shutdowns can help mitigate dangerous situations. The illustration below shows a SLA Multiloop and Multifunction Logic Solver installed in a high temperature and flow Safety Instrumented System (SIS) application.

This application requires that a temperature, pressure, and volumetric flow signal be used to calculate mass flow to ensure a safe and proper flow rate to the process. Should mass flow or temperature rise too quickly, a dangerous process condition could occur.

Three loop-powered transmitters are powered and wired into the three isolated SLA input channels. The SLA uses built-in Rate of Change Alarms that monitor mass flow and temperature over time to prevent unwanted surges in process conditions that could lead to a dangerous situation. The SLA uses voting logic (1oo2) to quickly shut down the process in the event of quick increases of mass flow or temperature.

To minimize nuisance trips the alarms are configured as high availability, which means they will not trip if there is an input failure, only when the rate of change event occurs in temperature and/or mass flow. To ensure the integrity of the safety function, input faults along with any system faults are signaled to the BPCS.

The remote BPCS is continually updated with process conditions by receiving three analog outputs from the SLA representing temperature and pressure readings along with the calculated mass flow. The HART signal from the connected temperature and pressure transmitters is passed-through the SLA so any monitoring of HART variables and diagnostics or programming of these connected instruments can be performed. Note that since calculated mass flow is an internally derived output source no HART signal is passed through to the third analog output channel.

Status of the shutdown function and any input or SLA faults are also sent to the BPCS via SLA relay output contacts. An input contact is used to manually reset any latching alarms, faults or relays. A system startup delay is set to suppress flow and temperature alarms which would initiate the shutdown logic. All inputs, outputs, alarms, internal variables, and faults along with various other parameters are transmitted via a secure digital and read-only MODBUS/TCP signal over Ethernet.

Key attributes:

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- -40 to 85 degrees Celsisus ambient temperature operating range

- Rugged aluminum casing which helps dissipate heat and provides protection against radio frequency and electromagnetic noise in harsh environments

- Crital HART pressure and temperature transmitter data passed through SLA to BPCS

- Voting logic and mass flow calculations easily programmed

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

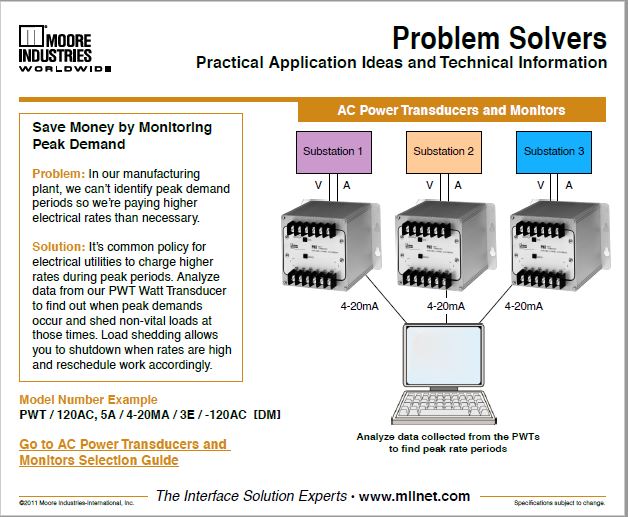

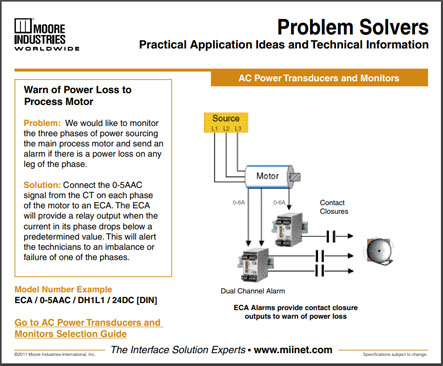

Why Monitor Power?

Why monitor power usage in your process? With AC power consumption and measurement drawing ever-more attention throughout the process industries, an understanding of basic AC parameters becomes increasingly important. Our free downloadable Power Transducer’s User Guide uses illustrations and simple definitions to explain the basics of AC power and its uses in the process industries. Monitoring your process’s power usage has never been more important, as many businesses are attempting to cut down on unnecessary power use with efforts to go green and contribute to the conservation of our environment. Download our free Power Transducers User’s Guide to see how Moore Industries can help you effectively monitor your power usage so you can ensure you are using only the power you need, saving you money while reducing your environmental impact.

Why monitor power usage in your process? With AC power consumption and measurement drawing ever-more attention throughout the process industries, an understanding of basic AC parameters becomes increasingly important. Our free downloadable Power Transducer’s User Guide uses illustrations and simple definitions to explain the basics of AC power and its uses in the process industries. Monitoring your process’s power usage has never been more important, as many businesses are attempting to cut down on unnecessary power use with efforts to go green and contribute to the conservation of our environment. Download our free Power Transducers User’s Guide to see how Moore Industries can help you effectively monitor your power usage so you can ensure you are using only the power you need, saving you money while reducing your environmental impact.

What are some benefits of Monitoring Power Usage?

By continuously monitoring your power usage you will be able to trend and detect which equipment or instruments are consuming considerable amounts of power. This gives you the opportunity to take corrective action when necessary. Continuous power usage monitoring also helps to ensure that you are being charged only for the power you are using.

Plus, improvements you make to ensure machinery is operating effectively and efficiently reduce your demand on the power grid and reduce the overall impact on the environment

How can Moore Industries Help?

Moore Industries created this Power Transducers User’s Guide with illustrations and simple definitions to explain the basics of AC power and its uses in the process industries, which can be downloaded below. After reading this guide you should be able to apply the basic principles needed to use power transducers. In this guide you will find the following information:

- Beginning Definitions for Electricity and AC Power Measurement

- Basic Concepts of AC Power

- Common AC Power Systems

- Monitoring Common AC Power Systems

- Taking Watt and VAR Measurements

- Reference Charts, Calculations, and Wiring Diagrams

- Power Transducers Available from Moore Industries

Download our Power Transducer User’s Guide to learn how you can effectively employ our power transducers to save your plant money, reduce your unnecessary power usage, and limit your overall impact on the environment.

Do you already know about AC Power Monitoring or want to learn more about Moore Industries AC Power Transducers? Check out this blog to learn more.

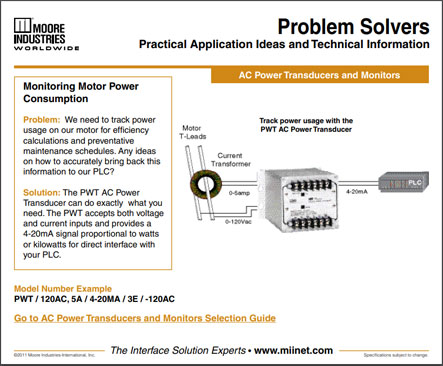

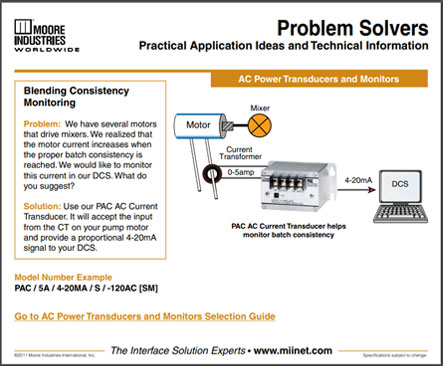

Instruments designed with Users in Mind

Monitoring and recording voltage and current requires the use of volt and current transducers. The output signals from these transducers can be used to provide input to meters and activate alarms or other devices should current or voltage fall outside of a safety range.

Monitoring and recording voltage and current requires the use of volt and current transducers. The output signals from these transducers can be used to provide input to meters and activate alarms or other devices should current or voltage fall outside of a safety range.

Moore Industries power transducers feature utility-grade design and construction to provide years of accurate operation. Each model also features a low burden power requirement and a proven ability to maintain stability. For the ultimate quality check, we burn-in and thoroughly test every single unit manufactured. Our rugged and reliable power transducers are the ideal solution for monitoring power usage within your process. Here are some of the main benefits of the Moore Industries Power Transducers:

- Low burden power requirement

- Stable function/operation

- Resilient terminal blocks

- Easy-to-install

- Standard wiring and footprint sizes

- Utility-grade design and construction

- Rugged metal housing

Discover AC Power Transducers from Moore Industries here.

Contact us at any time regarding your Power transducer needs – we’ll be glad to help! Call Toll-free in US and Canada: +1-800-999-2900 or +1-818-894-7111.

Email us at This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our Contact page and complete the form.

Need to learn the basics about AC Power Transducers? Download our Power Transducers User’s Guide

Moore Industries’ article The Ins and Outs of I/O has been published by Control Engineering Europe in the June 2022 issue (p. 22). The article outlines the various types of I/O, pointing out that although defining the difference between Local I/O and Remote I/O is straightforward, distinguishing Distributed I/O is more nuanced and complicated. More complex Distributed I/O harnesses all the capabilities of Remote I/O and more because it involves equipment that can be distributed throughout a process plant or automation facility. This equipment contains its own advanced CPU and real time operation system that allows localized control and monitoring, without the concern of continuous communication with its host Controller/CPU. Read the article to get the whole story.

Moore Industries’ article Sensor Integrity Ensures Temperature Measurement Accuracy has been published by InTech Focus in the May 2022 Temperature & Pressure eBook issue (p. 19). The article points out that whether you are measuring or controlling temperature, measurement accuracy begins with the sensor – better sensors make better process measurements. The article goes on to address the multiple factors that affect the accuracy and provides effective techniques and selection tips. Read the article to get the whole story.

We’ve been busy revamping our temperature assemblies and sensors product offering to make it far easier for you to find what you need and tell us what you want. Many items that were custom-order are now selectable by a part number, with the necessary variables easy to factor in. To make it easy to find the part you need, our four “RTI” Ready-to-Install assemblies data sheets have been consolidated into one titled Temperature Assemblies – WORM and Solid Sheath Sensors.

We’ve been busy revamping our temperature assemblies and sensors product offering to make it far easier for you to find what you need and tell us what you want. Many items that were custom-order are now selectable by a part number, with the necessary variables easy to factor in. To make it easy to find the part you need, our four “RTI” Ready-to-Install assemblies data sheets have been consolidated into one titled Temperature Assemblies – WORM and Solid Sheath Sensors.

This new data sheet is designed to acquaint you with the spectrum of our sensors, thermowells and accessories to help you select and configure the components you need for your unique application. Information in this data sheet includes:

WORM Flexible Temperature Assemblies

- WORM Sensor Specifications

- Ready-to-install Thermowell Temperature Assemblies

- Worm Surface Mount Assemblies

- WORM Upstream Flex-Armor Assembly

- WORM Replacement Kits

- Build Your Own WORM

- Thermowells Only

- Replacement Sensors and Components

Solid Sheath Temperature Assemblies

- Full Thermowell Assembly

- Fixed Immersion Assemblies

- Sensor Assemblies Using Existing Thermowells

- Flex Armor or Stainless Steel Braid Sensors

- Replacement Sensors and Spare Parts

All of the model and part numbers you need for your temperature assembly are provided in this new data sheet. You can download the data sheet from our Download Center or use this link.

All of the model and part numbers you need for your temperature assembly are provided in this new data sheet. You can download the data sheet from our Download Center or use this link.

We have also updated our online catalog Temperature Assemblies and Sensors section with new temperature assembly groupings, and access to the data sheet right on each product group page allowing you to easily start your request for a quote. See the products available in the online catalog Temperature Assemblies and Sensors section

Contact us at any time regarding your particular temperature assembly configuration – we’ll be glad to help! Call Toll-free in US and Canada: +1-800-999-2900 or +1-818-894-7111.

Email us at This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our Contact page and complete the form.

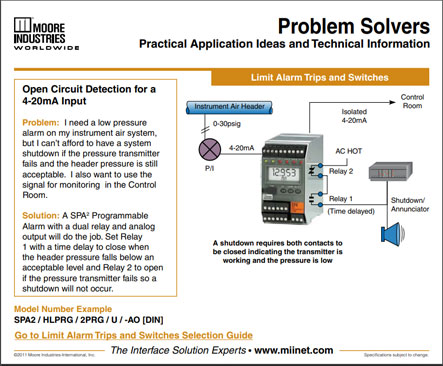

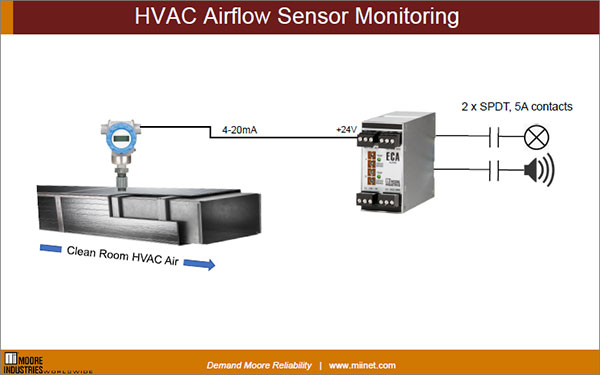

The ambient air or environment plays a critical role in many manufacturing industries that require maintaining sterile or aseptic environments served by HVAC systems. Controlling different parameters, such as the air’s temperature and humidity is certainly vital for ideal manufacturing conditions. But if continuous flow rates are not also tightly monitored and controlled, humidification and temperature controlling equipment cannot perform as originally designed.

To verify that proper flow rates are supplied to the lab’s pneumatic valves, an ECA Current Alarm Trip is used to alarm on low airflow conditions. The ECA comes standard with two SPDT alarm outputs and a TX option (24VDC @ 25mA) that powers the loop powered Airflow Sensor so no additional wiring to a separate 24DC auxiliary power supply is needed. Setpoints for the two alarms are set with front panel potentiometers adjustable from 0-110% of input span. This is very useful for NAMUR compliant type Airflow Sensors as one of the two alarms can be set at >21mA, indicating a failed transmitter condition per NAMUR standards. Field configurable via selectable jumpers, each alarm function can be site configured for high/low and Failsafe/Non-Failsafe relay action. This fast acting 50msec response time alarm, also comes standard with an adjustable deadband capability of 1-20%.

Key attributes:

- Powers and Receives 4-20mA Signal from Airflow Sensor

- Dual field configurable alarms capable of alarming on NAMUR failure output range from Airflow Sensor

- Relays rated 5A, 250VAC

- 50msec response time

- Adjustable deadband for each alarm

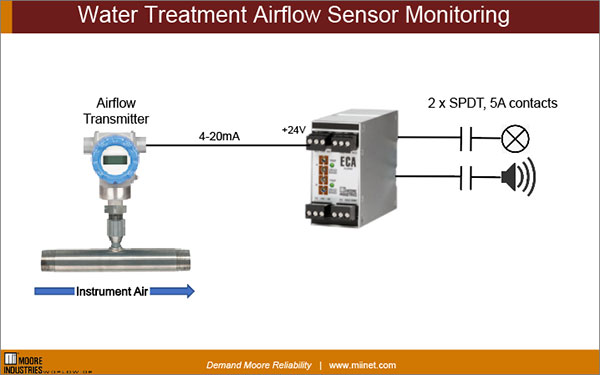

In municipal and industrial wastewater treatment, aeration is part of the secondary treatment process. The activated sludge process is the most common option in secondary treatment. In industrial use, a common method of aeration is air diffusion method, in which air is diffused into a receiving vessel containing counter-current flowing water, to remove dissolved gases, such as carbon dioxide, Hydrogen Sulfide or methane, and to oxidize dissolved metals such as iron. If air header flow rates being supplied by compressors are not sufficient, the secondary treatment process will be incomplete and may yield contaminated water to rivers and other environmental water sources.

To verify that proper flow rates are supplied to the lab’s pneumatic valves, an ECA Current Alarm Trip is used to alarm on low airflow conditions. The ECA comes standard with two SPDT alarm outputs and a TX option (24VDC @ 25mA) that powers the loop powered Airflow Sensor so no additional wiring to a separate 24DC auxiliary power supply is needed. Setpoints for the two alarms are set with front panel potentiometers adjustable from 0-110% of input span. This is very useful for NAMUR compliant type Airflow Sensors as one of the two alarms can be set at >21mA, indicating a failed transmitter condition per NAMUR standards. Field configurable via selectable jumpers, each alarm function can be site configured for high/low and Failsafe/Non-Failsafe relay action. This fast acting 50msec response time alarm, also comes standard with an adjustable deadband capability of 1-20%.

Key Attributes:

- Powers and Receives 4-20mA Signal from Airflow Sensor

- Dual field configurable alarms capable of alarming on

NAMUR failure output range from Airflow Sensor - Relays rated 5A, 250VAC

- 50msec response time

- Adjustable deadband for each alarm

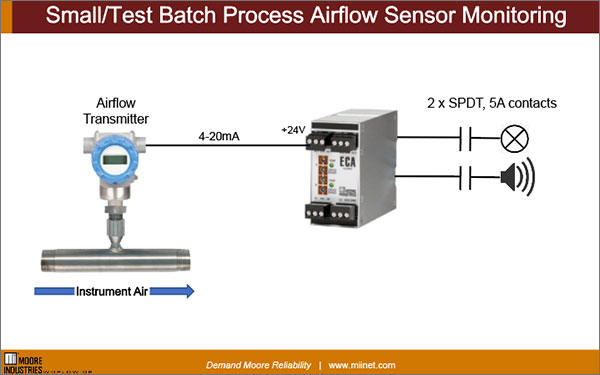

Many industrial facilities have R&D divisions or labs onsite to assist with small batch runs or testing to ensure that large scale production has met or will meet quality control standards. Often these labs are filled with smaller pneumatic valves that use air from onsite industrial compressors. If air header flow rates being supplied by these compressors are not sufficient, expensive test batches can be ruined or critical lab results can fail.

To verify that proper flow rates are supplied to the lab’s pneumatic valves, an ECA Current Alarm Trip is used to alarm on low airflow conditions. The ECA comes standard with two SPDT alarm outputs and a TX option (24VDC @ 25mA) that powers the loop powered Airflow Sensor so no additional wiring to a separate 24DC auxiliary power supply is needed. Setpoints for the two alarms are set with front panel potentiometers adjustable from 0-110% of input span. This is very useful for NAMUR compliant type Airflow Sensors as one of the two alarms can be set at >21mA, indicating a failed transmitter condition per NAMUR standards. Field configurable via selectable jumpers, each alarm function can be site configured for high/low and Failsafe/Non-Failsafe relay action. This fast-acting 50msec response time alarm also comes standard with an adjustable deadband capability of 1-20%.

Key Attributes

- Powers and Receives 4-20mA Signal from Airflow Sensor

- Dual field configurable alarms capable of alarming on

NAMUR failure output range from Airflow Sensor - Relays rated 5A, 250VAC

- 50msec response time

- Adjustable deadband for each alarm

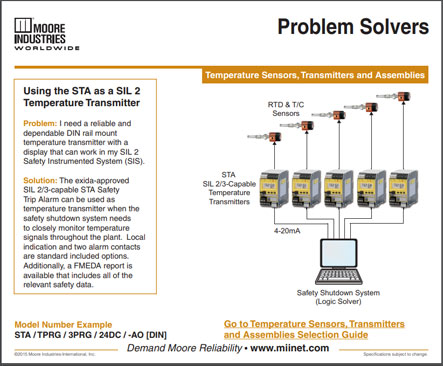

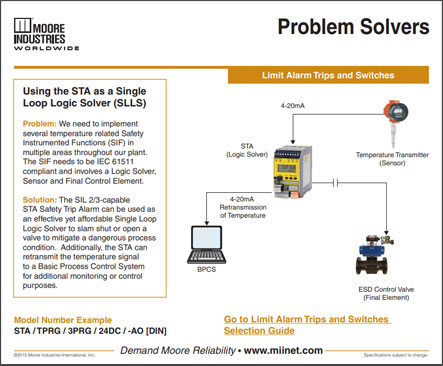

The main production facility for a UK fertilizer company produces ammonium nitrate which is subject to the UK Control of Major Accident Hazards (COMAH) regulations. This organization ensures that businesses take all necessary measures to prevent major accidents involving dangerous substances such as this one and is enforced by the UK Health & Safety Executive (HSE). A review of the emergency shutdown system under IEC61508 Functional Safety Standard revealed an urgent upgrade was needed of electrical, control and instrumentation to satisfy SIL2 System designation.

One of the main areas needing attention was the critical temperature monitoring of the reactor process and the requirement for hardwired alarms on selected Safety Loops because alarms were being generated by a combination of the diverse technology being used and the alarm software of the DCS. Modern safety standards do not allow combining control and shutdown systems in the same DCS.

The Moore Industries STZ and STA were chosen by the company and HSE to provide a hardwired shutdown system meeting the requirements for SIL2 system capability. The highly accurate STZ temperature transmitter features sensor backup and failover capability along with a flexible configuration to accept a range of existing thermocouples. The STA trip alarm, which is the company’s plant standard for SIL hardwired trip alarms, features highly reliable relays and configuration software that is easy-to-use yet robust.

The STZ accurately measures redundant temperature sensors and provides measurement and sensor diagnostics. Should the primary sensor fail, the backup/failover sensor will be transmitted to the STA, Safety Trip Alarm. The STA relays trip when conditions exceed the temperature high and low limits for process safety, triggering an alarm and emergency shutdown. The STA also retransmits its temperature input back to the DCS, via its 4-20mA analog output.

Key attributes:

- SIL2

- Sensor Backup/failover of STZ

- Relay trips

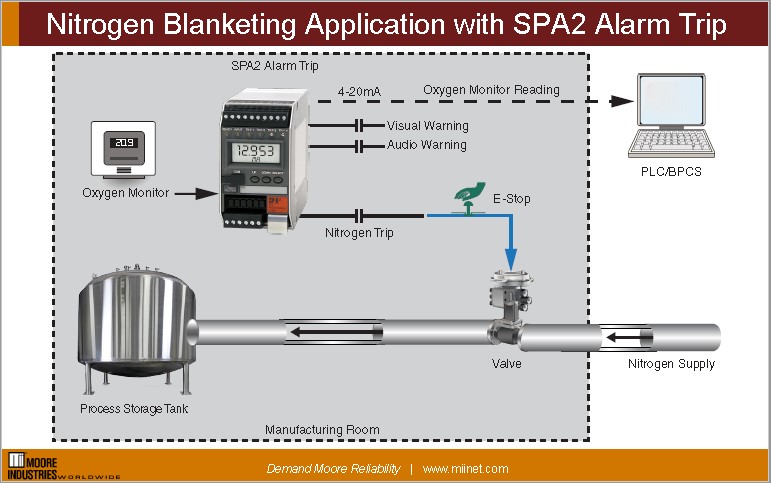

The quality and effectiveness of pharmaceutical products is critical to the industry and its users. To ensure the quality stays intact, nitrogen is often used for packaging purposes and other processes inside the manufacturing facilities. Because nitrogen is an inert gas, it is often used to exclude or push oxygen out of certain areas, including packages and containers.

Pharmaceutical companies use a method called nitrogen blanketing to protect processes that are used to make their products. Nitrogen blanketing strategies are implemented during production, storage, transportation, and final packaging. Nitrogen blanketing involves adding nitrogen liquid or gas to fill the area between the fill line of a process storage vessel’s content and the top of that vessel. The nitrogen displaces the oxygen inside, which helps ensure that oxygen and moisture don’t contaminate the product or cause a potentially explosive situation due to excess oxygen.

The level of oxygen inside of the Manufacturing Facilities where nitrogen is used must be monitored because the same nitrogen used for oxygen displacement to preserve the valuable contents of the vessel could become deadly to the employees working in the room. Nitrogen leaks can cause the air in the room to become oxygen-deficient, which could cause the employees to suffocate.

In the above application, an Oxygen Monitor is utilized in conjunction with a Moore Industries SPA2 Programmable Limit Alarm Trip to help avoid this potentially dangerous situation. The Oxygen Monitor provides the oxygen level input to the SPA2 from the inside of the room where the process is occurring. The SPA2 provides two or four independent and individually configurable alarm relay outputs, one of which can be designated to shut off the flow of nitrogen supply when the Oxygen Monitor detects low oxygen in the room; which could be caused by a nitrogen leak in the Process Storage Tank. An E-stop can also be wired in series so that operators can shut off the nitrogen supply manually. The other SPA2 relays can be used to alert employees by being wired to audible and visual warnings. An optional AO analog output on the SPA2 can communicate the Oxygen Monitor readings to a PLC, BPCS or auxiliary safety system.

Key Attributes

- Programmable input/output parameters and “Universal” DC or AC power input.

- Two or four independent and individually configurable alarm relay outputs.

- Optional AO analog output, any range between 0-20mA and 0-10V

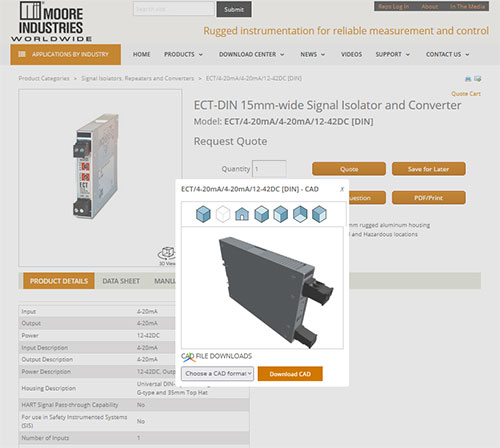

Over the past few months, we have been adding more than 1,000 downloadable 3D CAD models for our most popular products to our online catalog. These models are available in multiple file formats for use in the most popular CAD design systems, making it easy to include Moore Industries products in your system designs.

This new feature of the online catalog provides a pop-up 3D viewer that allows you to see different views of the selected product, rotate the model to any viewing angle and zoom in to view detail. Models can be downloaded and saved for use in 3D CAD systems for inclusion in panel designs and process loop and system designs.

The 3D files are compatible for many popular CAD systems including Pro/ENGINEER, Autodesk Inventor, Solidworks, Parasolid, AutoCAD, Catia, IGES, Anvil, CADKey, IronCAD, Mechanical Desktop, ACIS, SDRC I-DEAS, and Unigraphics in 3D formats.IGS, .NEU, .PDF, .SAT, .STP, .X_T, and 2D formats .DWG and .DXF. Products that feature a 3D CAD model are identified with a “3D View” icon, and a download button is available on each product page.

Dropping standard product models into a CAD design streamlines the engineering design process, makes it easier for your purchasing team to source the products, simplifies installation and maintenance for the maintenance team, and can shorten lead times for stocking spare products. Moore Industries Engineering Director Bob Myles commented that “the 3D CAD models will make it much easier for our customers to integrate precise Moore Industries product into their system designs that reduces drawing time, shortening their engineering timeline”.

We’ll continue to add new models with each new product release.

See the available 3D models in the Moore Industries website online catalog

All trademarks, logos and brand names mentioned on this news release are properties of their respective owners.

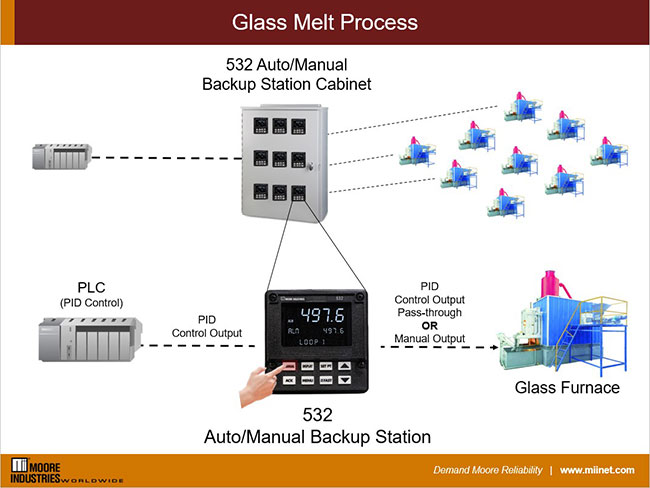

When a glass recycling division was upgrading one of their recycling facilities from sorting glass 10mm in size (or larger) down to 3mm in size, which provided more business opportunity and diverted more glass from landfills, they looked to Moore Industries 532 Auto/Manual Backup Stations to provide manual backup of their critical Melt Furnace PID control loops. Three panels were fitted with twenty-five 532 Auto/Manual Backup Stations to monitor the host PLC’s PID control for each Melt Furnace chamber. Maintaining temperature control for the Melt Furnaces is paramount and should the primary host controller fail, solidified glass could severely damage and perhaps ruin the furnace. These 532 Auto/Manual Backup Stations were chosen because they can sit passively on the PID control signal from the PLC and if that signal should fail, the 532 automatically generates a control signal based on the last known host PLC value allowing for seamless manual takeover. In addition, during normal operation the 532 allows local operators to quickly switch between Host and Manual control modes when and if required. This provided the recycling facility with the critical redundancy and optional local control that they needed for their Melt Furnaces.

The plant engineers’ control strategy utilized the following strategy:

- Under normal circumstances, the 532 Auto/Manual Backup Station was left in AUTO mode and allows the 4‐20mA control signal from the PLC to pass straight thru unimpeded to the Melt Furnace’s heating system.

- If the PLC should fail, the 532 Auto/Manual Backup Station automatically detects this and enters MANUAL mode and maintains the last known output value. This then allows plant operators to manually control the output signal going to the Melt Furnace heating system until the PLC is repaired.

- Upon failure of the host PLC system, the 532 Auto/Manual Backup Station provides an alarm contact to a local klaxon that alerts plant personnel that they have lost primary host control.

- If at any time during normal operation the plant operators needed to take manual control, the MANUAL mode button on the 532 allowed them to do so.

Moore Industries 532 Auto/Manual Backup Station ensures the integrity of your processes with maximum reliability. Isolated inputs and outputs guard against electrical interference, the front face meets NEMA 4X standards for watertight operation, and solid metal housing and sturdy rubber keys enhance durability. The 532 has three bright, crisp vacuum fluorescent digital display areas, with two offering up to nine characters of true alphanumerics. Additional operator-friendly features include custom programmable alarm messages, keys that illuminate when in use and an easy-to-use menu system.

Key Attributes

- Provides manual backup of critical control loops.

- Transfers between REMOTE and LOCAL modes via keypad command, digital input, RS-485 communications or loss/return of control signal.

- Upon keypad command or loss of signal, generates a control signal based on the last known HOST value or preprogrammed value and provides alarm output of signal loss.

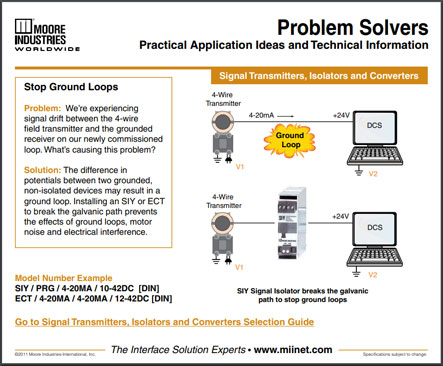

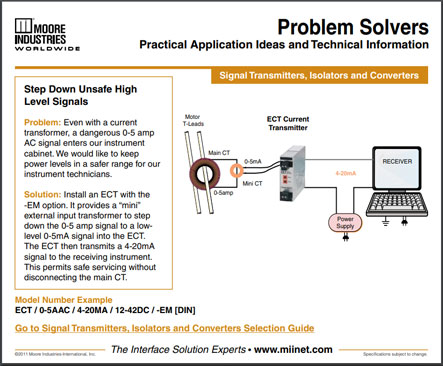

Signal isolators are highly economical solutions to common and costly problems that plague many of today’s smart process loops such as ground loop and ambient electromagnetic noise problems. But they do much more than that: they can be used to share and split process signals and even enhance your plant-wide HART investment by also passing valuable HART data to and from your host systems.

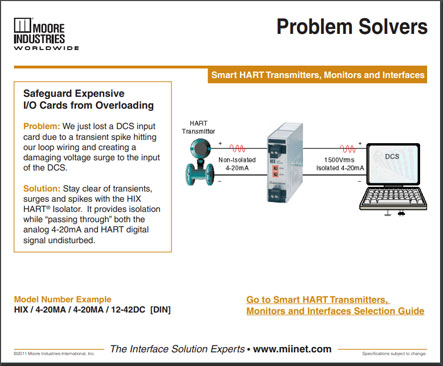

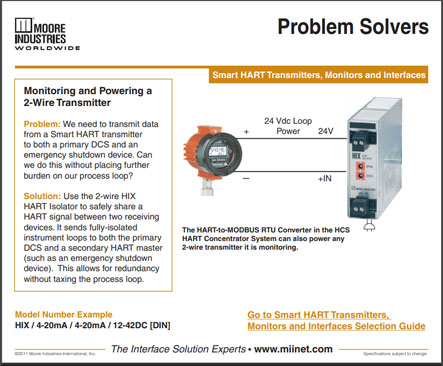

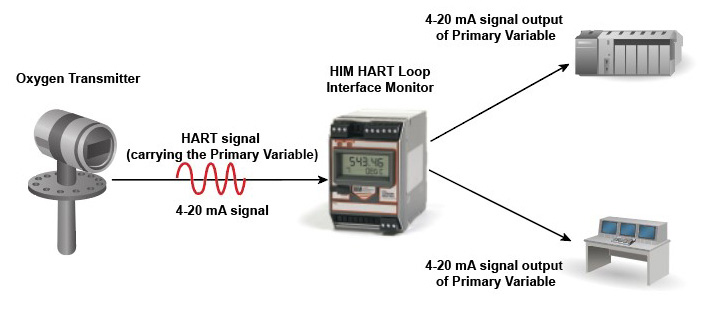

The 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT enable you to safely share the HART output of one transmitter with a secondary control or recording device. This allows for redundancy without further burden on or risk to a process loop. With up to 1500Vrms of isolation capability, these HART passthrough isolators protect I/O cards from damaging surges, spikes and transients. Employing these HART isolators to loops also breaks the common galvanic path that can pass dangerous overloads from the BPCS or control host to the transmitter or vice-versa– even when the equipment is supposedly “isolated” already.

The 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT enable you to safely share the HART output of one transmitter with a secondary control or recording device. This allows for redundancy without further burden on or risk to a process loop. With up to 1500Vrms of isolation capability, these HART passthrough isolators protect I/O cards from damaging surges, spikes and transients. Employing these HART isolators to loops also breaks the common galvanic path that can pass dangerous overloads from the BPCS or control host to the transmitter or vice-versa– even when the equipment is supposedly “isolated” already.

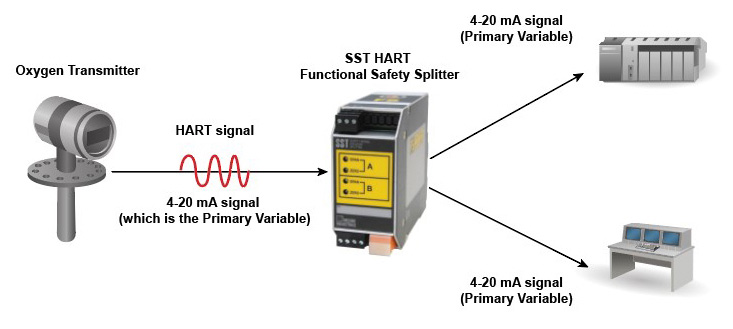

The exida-approved, SIL 3 capable 2-wire (loop powered) SSX and 4-wire (line/mains powered) SST Safety Isolators and Splitters are ideal for use in settings where safety is critical. They protect safety systems by isolating an SIS from basic process control or monitoring systems so that disconnections or other failures don’t impact the safety system. They also have 1500Vrms of isolating capability to protect safety I/O cards and systems from surges, spikes and transients in the field. Standard 20V/m RFI and EMI protection stops the harmful effects caused by radio frequencies and electromagnetic interference.

The exida-approved, SIL 3 capable 2-wire (loop powered) SSX and 4-wire (line/mains powered) SST Safety Isolators and Splitters are ideal for use in settings where safety is critical. They protect safety systems by isolating an SIS from basic process control or monitoring systems so that disconnections or other failures don’t impact the safety system. They also have 1500Vrms of isolating capability to protect safety I/O cards and systems from surges, spikes and transients in the field. Standard 20V/m RFI and EMI protection stops the harmful effects caused by radio frequencies and electromagnetic interference.

Like the HIX and HIT, the SSX and SST protect and enhance loops and also pass valuable HART data from the field transmitter to host systems and vice-versa. In addition, the SST Splitter model takes the input from one of your process signals and creates two identical, completely isolated outputs to two separate monitoring or control devices. This facilitates maintenance on either output loop without losing the signal on the other output loop. Plus, the optional Loop Maintenance Zener Diode allows the SSX and SST to be removed from the loop for maintenance without interrupting your safety function.

See all of our HART Isolators in the online catalog or contact us for a quote.

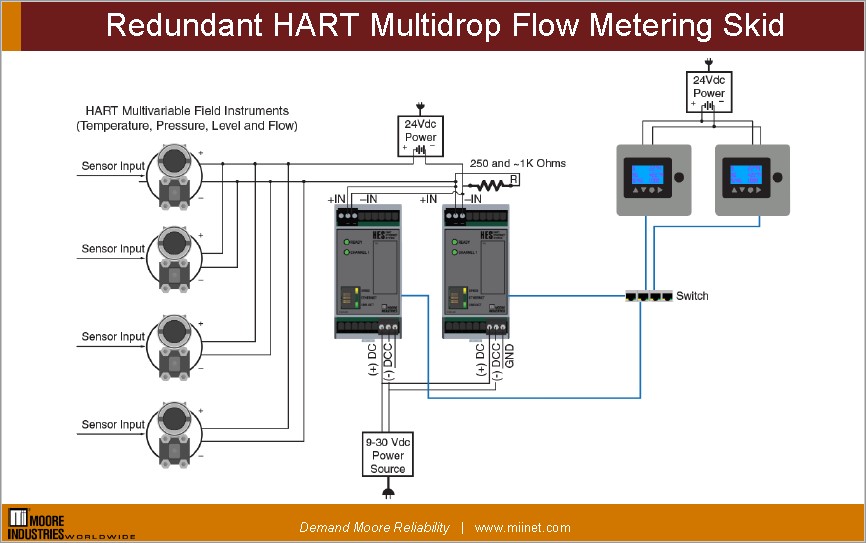

When the gas metering division for a customer in Malaysia needed a way to provide redundancy and high measurement resolution for their Metering Skids, Moore Industries had the solution with the HES HART to Ethernet Gateway System. The customer’s gas metering application required four HART transmitters to be multidrop wired for communication with two FLOW computers, for redundancy. Their existing system allowed for a multidrop of four HART transmitters back to one flow computer; however, their flow computers did not allow for primary and secondary HART master modes. This meant redundancy was not available to the customer, as only one flow computer was able to see the transmitter measurements. If redundant input cards were wired into the process using HART communication, only one transmitter would be available to send its signal back to the flow computers. As a result, two of the customer’s main requirements for the application could not be met at the same time.

Moore Industries HES can be configured as a HART primary or secondary master, capable of having up to 16 HART devices on a multidrop network in a single-channel configuration (64 in a four-channel configuration). With this capability, two HES were able to simultaneously receive the measurements from the four HART transmitters and act as redundant masters. By wiring two redundant flow computers to the two HES through a network switch, the flow computers were also able to simultaneously receive the HART transmitter measurements; this allowed the customer to meet their need for redundancy. In addition, the HES provided the best available resolution for their transmitter measurements via HART communication.

Key Attributes

- Can be configured as a Primary or Secondary HART Host and polls up to 16 field devices on each of its four channels (total of 64 field devices maximum per HES).

- High-resolution quality by utilizing HART protocol.

- Acquisition of both process and diagnostic data from up to 64 smart HART devices for Ethernet-based systems and hosts.

The Moore Industries family of reliable surge suppressors protect your process against failures caused by lightning, power spikes, and other overvoltage damage that can lead to a reduction in measurement accuracy, product quality, and unnecessary/costly shutdowns. Our suppressors ensure the most effective suppression available, providing up to 3kA of surge protection. They are also maintenance and hassle free with easy installation and a safety feature that automatically resets the suppressor after each surge.

Our Field-Mount/DIN Mount Surge Suppressor can be placed inside of Moore Industries BH or SB enclosures or mounted on DIN rail. You can use the surge suppressor to protect your HART digital/analog signal lines due to its ability to allow HART signals to pass through. This suppressor exceeds severity level 4 of IEC 61000-4-4 with 3kA/line of surge protection. It is encapsulated and suitable for the harshest industrial environments.

Our Field-Mount/DIN Mount Surge Suppressor can be placed inside of Moore Industries BH or SB enclosures or mounted on DIN rail. You can use the surge suppressor to protect your HART digital/analog signal lines due to its ability to allow HART signals to pass through. This suppressor exceeds severity level 4 of IEC 61000-4-4 with 3kA/line of surge protection. It is encapsulated and suitable for the harshest industrial environments.

Moore Industries DIN-Plug Surge Suppressor exceeds severity level 4 of IEC 61000-4-4 and 61000-4-5, providing 2.5kA/line of surge protection. The DIN-Plug Surge Suppressor has lightning-fast response time and is designed to fit onto any Moore Industries’ 2-prong terminal block header. This economical, small, and powerful surge suppressor has the suppression technology you need in the field with a compact design that will fit in the most cramped control rooms.

The Data Line Rail-Mount Surge Suppressor is designed to mount on any Top Hat or "G" type DIN-rail for protection of digital signals. It will work with RS-422 and RS-485 communication lines and will ensure that your transmitter and receiver are both protected from overvoltage damage on long communication runs. This unit also exceeds severity Level 4 of IEC 61000-4-4 recommendations, providing sub-nanosecond response time to stop failures.

Download the data sheet or request a quote today

Moore Industries offers a comprehensive line of power supplies to help ensure reliable power goes to all your devices and meets your needs in noise reduction, instrument accuracy, data consistency, and stable communication.

The ECS Economy Power Supply is an ideal process loop component for use with noise prone 2-wire transmitters and data communications equipment, in most cases exceeding performance specifications of higher-priced supplies. The  ECS features superior isolation with 2500 Vrms protection so that process signals will not be affected by even severe ground loops, motor noise, or other electrical transients. Though the standard ECS is configured at the factory to 117Vac or 230Vac, it can be field-configured to meet your specific needs.

ECS features superior isolation with 2500 Vrms protection so that process signals will not be affected by even severe ground loops, motor noise, or other electrical transients. Though the standard ECS is configured at the factory to 117Vac or 230Vac, it can be field-configured to meet your specific needs.

Moore industries DPS DIN Power Supplies are designed especially for industrial environments and are ideal for powering 2-wire transmitters and data communication modules. The DPS 240 can be used to power a maximum of twelve 4-20mA loops, while the DPS 1200 can power a maximum of sixty 4-20mA loops. Each DPS unit provides complete isolation between the input and output terminals and the unit case, ensuring that power supply fluctuation from line power will not affect instrument accuracy.

The SMP Surface-Mount Power Supply is a compact, precision regulated, linear DC instrument power supply which requires minimal user maintenance and will power large numbers of 2- and 4-wire process instruments. It is the ideal companion to multiple position card racks and rails, or instruments installed in a cabinet or sub-system. The SMP’s superior line and load regulating capabilities help ensure stable signals and that no expensive data loss occurs. All SMPs are designed to operate safely over a temperature range from 0oC to 50oC (+32oF to +122oF) and include full-time short circuit and overload protection to prevent electrical damage to the unit.

View these power supplies in our online catalog and download a data sheet, or request a quote today.

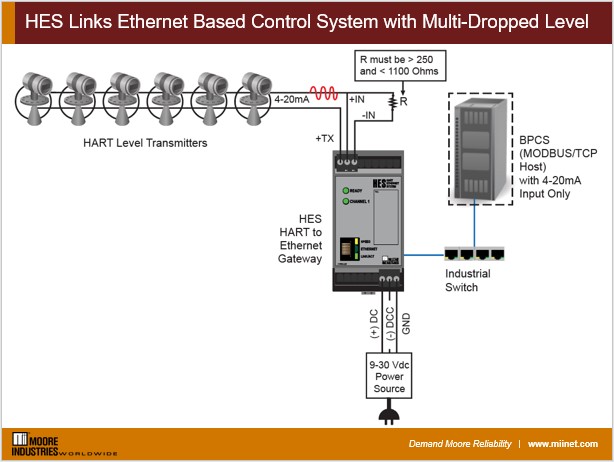

Gathering and communicating critical measurement and diagnostic data in oil and gas applications can be extremely challenging due to the harsh and remote conditions associated with these operations. A company in Kuwait recently needed a way to acquire data from dozens of radar LEVEL transmitters in the field, and in addition, provide power to these transmitters because there were limited power sources available at the site. Moore Industries HES HART to Ethernet Gateway System was able to fulfill both of these requirements. The client multi-dropped six output loop-powered radar level transmitters to each single-channel HES for data acquisition, and utilized the HES transmitter excitation power supply feature to power the transmitters. The gathered process and diagnostic data was then sent over MODBUS/TCP from the HES back to the client’s BPCS (MODBUS/TCP Host) for higher level control, data acquisition and monitoring functions.

The HES offers a flexible and economical way to gather process data and instrument diagnostics from smart HART instruments and share it over an Ethernet infrastructure via its embedded web server or with MODBUS/TCP and HART-IP hosts. This enables fast and seamless connectivity for advanced monitoring of critical process variables and parameters. In addition to the single channel configuration outlined above, the HES is also available in a four channel configuration supporting up to 64 HART devices. The HES communicates with all HART 5, 6 and 7 devices including smart valves, multivariable flowmeters, pressure, pH, level, and temperature transmitters and more.

Key Attributes

- Acquisition of both process and diagnostic data from up to 64 smart HART devices for Ethernet based systems and hosts.

- FDT/DTM programming, embedded webserver and MODBUS/TCP support seamless connection with all Ethernet based hosts.

- Embedded power supply supports powering of muti-dopped HART instruments over one twisted pair where power is limited.

A temperature excursion on the HPump system motor, when discovered in time, can mean that only some minor maintenance is needed. If that same temperature excursion isn’t caught early on, however, components such as front and rear bearings, windings, and thrust bearings can be damaged. Repairs are very costly and could impact production.

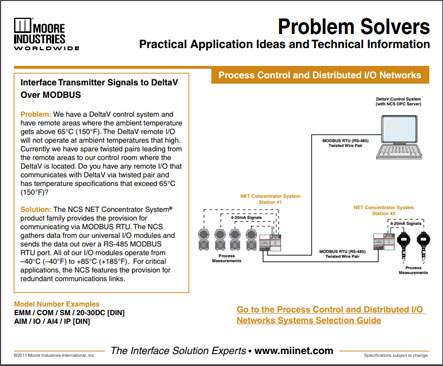

Call Moore Industries today or check out the NCS Net Concentrator System datasheet.

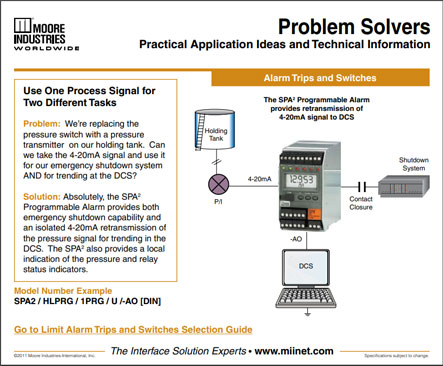

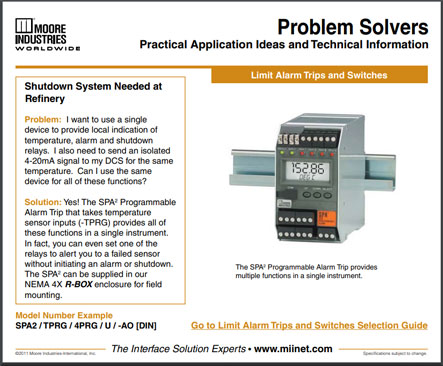

Moore Industries SPA2 Programmable Limit Alarm Trip is a highly versatile, fast and simple solution to your alarming needs. The SPA2 accepts signal inputs from a wide array of instruments and sensors, provides two or four independent and individually-configurable alarm relay outputs, and its analog output (-AO) option can reduce installation costs and time by providing both alarm and transmitter functions.

Call Moore Industries today at 1-800-999-2900 or download the SPA2 datasheet.

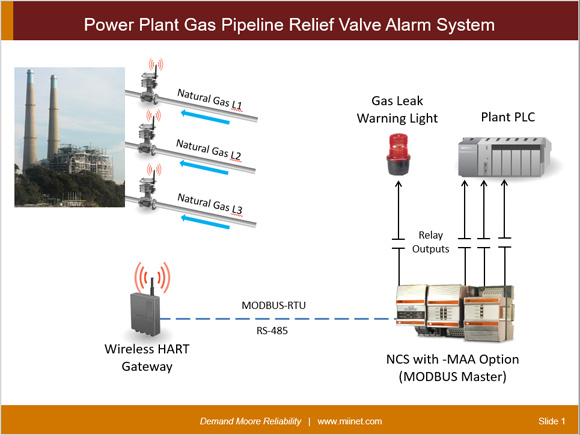

A Power Plant in the U.S. Northeast needed to monitor three safety relief valves on gas lines into their power plant. An alarm is required on each valve in case any of these relief valves experience a release of natural gas. Because it would have been too costly to run several new wires out to these valves from the control room PLC, they opted to implement a wireless solution coupled with a field mounted NCS Net Concentrator System.

Each relief valve was retrofitted with a WirelessHART positioner/monitor to relay its status back to the WirelessHART gateway. The NCS, acting as a MODBUS RTU Master, gathered the relief valve status from the gateway over RS-485 and provided the local alarming and annunciation. Alarms for each relief valve were quickly configured with easy-to-use web pages within the NCS. If any valve reported a leak, the NCS sent relay outputs to a flashing beacon and a PLC that was tied to the plant’s main SCADA and safety system.

The alarm function on the NCS system would normally be programmed using its embedded ISaGRAF control engine software, which is very powerful and versatile. However, for this straight forward multi-channel alarming application, they opted to add the –MAA Multipoint Analog Alarm option to the NCS EMM module. This option allows easy to configure alarming with prebuilt web pages that include simple pull-down menus and radio buttons., saving many hours of engineering time.

Taking advantage of existing HART DATA with minimal expense

Moore Industries’ article on How to Take Advantage of Existing HART Data with Minimal Expense has been published in Process Technology 115, 11.2019 issue (p. 18). The article points out that although there are 40 million HART instruments installed in the field, making HART the most dominant communications protocol used in process manufacturing facilities across the world, many existing control and monitoring systems do not support HART communication for 4-20mA devices. HART gateways like the HES fill in this gap, allowing end-users to strategically interface their HART smart devices with their control systems by selecting those devices that add the most value to their operations. The implementation of these HART gateways can be employed as part of the maintenance budget without having to allocate larger capital funds. This can be an affordable way of establishing a plant-floor-to-Ethernet backbone, and integrating valuable HART data into higher layers for further processing and analysis while leaving core automation tasks unaffected.

Moore Industries Instrument Panels and Systems engineering and design group provides turnkey solutions for your process, automation or Safety Instrumented System (SIS) monitoring and control needs. Moore Industries excels in designing and building compact and modular solutions used to monitor temperature, pressure, level, flow, and safety-related processes with high-performance instrumentation and components.

See the Instrument Panels And Systems in the Online Catalog or Call us at 1-800-999-2900

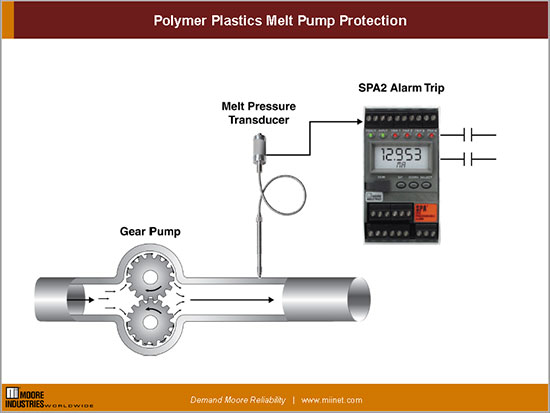

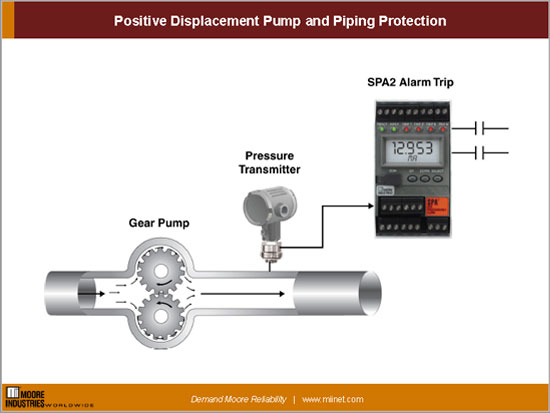

Melt pumps used in polymer production are a special high temp positive displacement pump used at the discharge of an extruder to assure a smooth, high temperature and high pressure (often several thousand psi) supply of the polymer to the filter screen and die for better throughput and uniformity of product. Blockage of the filter screen or die can cause spikes in pressure high enough that the die can be damaged or blown off the feed tap. When that happens, the released polymer will cool and harden at ambient pressure and temperature, requiring hours of cleanup. Downtime costs can be significant.

An alarm trip such as the Moore Industries SPA2 in conjunction with an appropriate pressure transmitter can prevent these overpressure failures, saving personnel hours and production losses. The SPA2’s fast response time of <256msec can trip an alarm fast enough to cut power to the pump motor in time to prevent or minimize damage.

Key Attributes:

- Fast response

- Easy set up

- Independent of the BPCS