Search Problem Solvers

Our WNM Wireless Network Module now has both Serial and Ethernet interfaces conveniently included into one model and has been updated with a new, sleeker housing.

Our WNM Wireless Network Module now has both Serial and Ethernet interfaces conveniently included into one model and has been updated with a new, sleeker housing.

The WNM provides accurate and reliable point-to-point and point-to-multipoint wireless connectivity between remote field sites when wires can’t be run for practical or economic reasons. It is a bi-directional, spread spectrum radio modem that delivers the flexibility and cost-saving advantages of wireless data transmission. Its Frequency Hopping Spread Spectrum (FHSS) communication ensures reliable, noise and interference immune, license-free wireless communications.

To learn about the updated WNM, see its new dimensions or for updated ordering information, download the data sheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. We have been using 3-wire RTDs in our process for years and are required to check the calibration once every 6 months. Each time we have checked the sensors we’ve noticed they have drifted. This requires us to re-calibrate our temperature transmitters. Do you have something you can suggest to help us reduce the drifting problem we regularly see in these sensors?

Q. We have been using 3-wire RTDs in our process for years and are required to check the calibration once every 6 months. Each time we have checked the sensors we’ve noticed they have drifted. This requires us to re-calibrate our temperature transmitters. Do you have something you can suggest to help us reduce the drifting problem we regularly see in these sensors?

A. The problem with 3-wire RTDs is that the lead wires build up small amounts of corrosion causing a lead wire imbalance which results in measurement errors. If these are Platinum 100 ohm RTDs, just one ohm of resistance change on any lead wire can represent a +4.7°F degree error. We suggest using 4-wire RTDs which compensate for unequal resistance in the lead wires. For this to be an option your temperature transmitters need to accept a true 4-wire sensor input. Some temperature transmitters, PLCs, and DCS input cards only accept 3-wire RTDs. Others indicate a place to connect a fourth wire, but do not use it for measurement.

You can also use Class A RTDs with 4 wires and a transmitter that can accept and be calibrated with a 4-wire RTD. Our Class A element RTDs with a .06% accuracy have been cycled for 1000 hours, and will hold their accuracy for a 5 year period.

You can learn more about using 3-wire and 4-wire RTDs in the white paper: A Practical Guide to Improving Temperature Measurement Accuracy.

These Moore Industries temperature transmitters are designed to accept true 4-wire RTDs: RIY, STZ, TCS, TDY, TFZ, THZ, THZ3/TDZ3, TPZ, TRY, TRX. For these and other Moore Industries temperature solutions, visit our Temperature Sensors, Transmitters and Assemblies page.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I would like to use either FDY/PRG/4-20MA/12-42DC [HPDN] or FDY/PRG/4-20MA/12-42DC [BH2NG] and I want to install it in a control panel enclosure rated Type 4X. I need to ensure it is suitable for Class I, Div 2. Which one is the best solution?

Q: I would like to use either FDY/PRG/4-20MA/12-42DC [HPDN] or FDY/PRG/4-20MA/12-42DC [BH2NG] and I want to install it in a control panel enclosure rated Type 4X. I need to ensure it is suitable for Class I, Div 2. Which one is the best solution?

A: The FDY/PRG/4-20MA/12-42DC [HPDN] without the BH2NG enclosure is Class I, Div 2 rated. It meets the Div 2 requirements when installed in your Type 4 box. You can download the certificate here.

The FDY/PRG/4-20MA/12-42DC [BH2NG], is an explosion proof transmitter approved for use in Class I, Div 1 hazardous areas. This is the same FDY device except it is housed inside the explosion proof/flameproof BH2NG enclosure. This BH2HG enclosure is also rated Type 4X & IP66 which means that it offers sufficient environmental protection to allow it to also be classified as a Class I, Div 2 or Non-Incendive device. The FDY/PRG/4-20MA/12-30DC/-ISF with the [HPDN] housing designation or enclosed in a BH type housing carries intrinsically-safe approvals.

Download the FDY datasheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. I have a temperature application that requires a 12-inch thermowell which can withstand a high temperature of 2,000°F. Most of what we have been using becomes brittle and breaks off at the tip. What would you suggest we use, and what type of sensors do you have that will work for us?

Q. I have a temperature application that requires a 12-inch thermowell which can withstand a high temperature of 2,000°F. Most of what we have been using becomes brittle and breaks off at the tip. What would you suggest we use, and what type of sensors do you have that will work for us?

A. We have several different types of metals we can suggest with maximum temperatures up to 2,160°F. Materials that will work well for the thermowell in your application are SS446, SS310, and Inconel 600.

For the sensor type, we recommend a thermocouple Type “K” with Inconel 600 material for the sheath. Also, using 2-inches of thermal-lagging for the thermowell will reduce heat going into the head.

If possible, remote mount the temperature transmitter away from the process connection. Even though Moore Industries temperature transmitters are rated up to 185°F, it could get too hot inside the head if it were mounted directly on top of the process. If you must mount the transmitter near the process connection, we suggest using a stainless steel housing and a ceramic terminal block to terminate the sensor at the process.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have an R-BOX in a Class 1 Div 2 location with a 120VAC instrument inside. Is this enclosure rated for this atmosphere? It does not appear to have a very good seal for this environment.

Q: We have an R-BOX in a Class 1 Div 2 location with a 120VAC instrument inside. Is this enclosure rated for this atmosphere? It does not appear to have a very good seal for this environment.

A: The R-BOX was designed to meet a Type 4X and IP66 rating, which is suitable for housing a Div 2 approved device. The hazardous area protection is provided by the non-incendive nature of the Div 2 rated device mounted inside. The enclosure simply needs to provide protection from the ambient elements or other flying conductive material.

Learn more by downloading the R-BOX datasheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. We want to measure bearing temperature in our motors to alert us of overheating. We have used a type of sensor which inserts into the side of the motor, but they leak and fail often. We would like to put something on the surface of the motor outside of the bearing housing, but we do not want something welded to the housing. What can you suggest?

Q. We want to measure bearing temperature in our motors to alert us of overheating. We have used a type of sensor which inserts into the side of the motor, but they leak and fail often. We would like to put something on the surface of the motor outside of the bearing housing, but we do not want something welded to the housing. What can you suggest?

A. The best solution for your application is a WORM sensor with a Magnetic Pad (-MPAD). The -MPAD has 40lbs of attraction and will hold up to a vibrating surface. We also suggest adding our 30G option to the RTD, in order to protect the RTD element inside the sheath from high vibration during motor operation. Standard fixed length sensors cannot withstand this vibration over time. The -MPAD with WORM sensor is easy to install on any ferrous metal surface.

Download the RTI-3 datasheet for more information.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

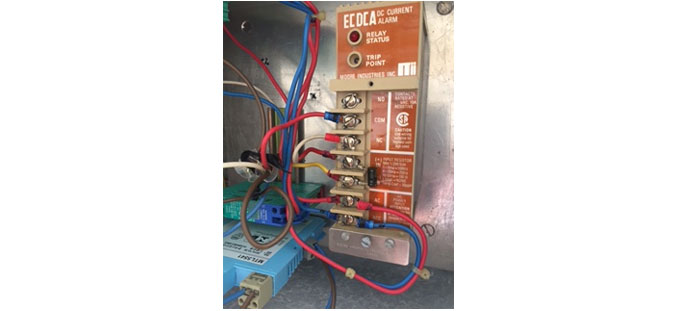

With electronic equipment making up much of process hardware, the potential for system noise and interference with process signals can come with the package. Frustrations from downtime and troubleshooting in your plant can be avoided by understanding the principles of signal isolation, conversion and interfaces. A comprehensive resource for determining which instrumentation to use, and how to use it, is Moore Industries’ Signal Isolators, Converters and Interfaces: The “Ins” and “Outs” White Paper. It has recently been updated and is ready for download from the Technical White Paperssection of the Moore Industries website.

With electronic equipment making up much of process hardware, the potential for system noise and interference with process signals can come with the package. Frustrations from downtime and troubleshooting in your plant can be avoided by understanding the principles of signal isolation, conversion and interfaces. A comprehensive resource for determining which instrumentation to use, and how to use it, is Moore Industries’ Signal Isolators, Converters and Interfaces: The “Ins” and “Outs” White Paper. It has recently been updated and is ready for download from the Technical White Paperssection of the Moore Industries website.

The white paper delves into the important ways signal isolators, converters and interfaces can be used and what to look for when specifying products for applications. It also expands on the specifics related to isolation in Safety Instrumented Systems (SIS) which are used to control dangerous processes and require installation of SIL-capable instruments.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Intrinsic safety is increasing worldwide as a method of hazardous area protection with monitoring and measurement instruments. Significant savings, both initial installation and ongoing maintenance costs, can be realized in intrinsically-safe (IS) facilities or projects by selecting an associated apparatus that encompasses the required IS barrier protection for your system. Available for download from the Technical White Papers section of the Moore Industries website, “Associated Apparatus: The Safe and Most Affordable IS Solution” gives you a brief introduction to intrinsic safety, the different components in an intrinsically-safe system, and the two different types of barriers.

Intrinsic safety is increasing worldwide as a method of hazardous area protection with monitoring and measurement instruments. Significant savings, both initial installation and ongoing maintenance costs, can be realized in intrinsically-safe (IS) facilities or projects by selecting an associated apparatus that encompasses the required IS barrier protection for your system. Available for download from the Technical White Papers section of the Moore Industries website, “Associated Apparatus: The Safe and Most Affordable IS Solution” gives you a brief introduction to intrinsic safety, the different components in an intrinsically-safe system, and the two different types of barriers.

Written by Tina Todd, Director of Engineering at Moore Industries, this paper explains the basic differences between simple apparatus with separate intrinsic safety barriers and associated apparatus with intrinsically-safe field connections. It addresses why selecting an associated apparatus which includes the IS barrier provides the most economic and effective use of IS technology. Additionally it addresses design, installation and maintenance considerations in selecting the best approach when choosing an intrinsic safety solution.

The techniques outlined in this paper are most applicable to the industrial process control sector including such industries as oil and gas production, oil refining, petrochemical, chemical, mining, pharmaceuticals, food & beverage, and pulp & paper.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am evaluating the SIX 2-wire Signal Isolator and Converter. Is this device auto-calibrated or will we need to calibrate it ourselves? Does it require two separate power supplies? The specs state that the output is loop powered but I am not clear on the input. Also, is it a problem if we supply both the input and output with the same power source? In our case, it would be the 53.5VDC power supply in the loop currently. We would need to run a parallel path. The input is intended to be a 4-20mA.

Q: I am evaluating the SIX 2-wire Signal Isolator and Converter. Is this device auto-calibrated or will we need to calibrate it ourselves? Does it require two separate power supplies? The specs state that the output is loop powered but I am not clear on the input. Also, is it a problem if we supply both the input and output with the same power source? In our case, it would be the 53.5VDC power supply in the loop currently. We would need to run a parallel path. The input is intended to be a 4-20mA.

A: The SIX is provided pre-calibrated from the factory for the input and output indicated in the model number. The device has potentiometers accessible on the front panel for making adjustments to the zero and span.

The SIX derives its operating power from the voltage that is applied to its output. It consumes 12V of the available voltage applied to its output. The SIX accepts a voltage or current input. If the input is 4-20mA, then the SIX will add 50 ohms of impedance to that loop.

Regarding supplying both the input and output with the same power source, the primary purpose of the SIX is to provide input to output galvanic isolation. Using the same power supply for both would defeat that isolation.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have been using your SPA series temperature transmitters in our hydroelectric power plants with excellent results. These devices have high protection against electromagnetic interference. We would like to purchase temperature transmitters for head mounting and rail mounting that have the same high level of isolation and protection against electromagnetic interference. The sensors are 10 Ohm Cu three wire RTDs and they represent the temperature of generator windings in the hydroelectric power plant.

A: Model SPA/TPRG/2PRG/U/-AO [DIN] provides 0.25 mA RTD excitation current. If it is performing well then our PC configurable temperature transmitters, which have the same excitation current, should also perform well. In that case we recommend the TRY series. The head mount style is model TRY/PRG/4-20MA/10-42DC [LH2NS]

If your SPA has the SP2 option instead (Model SPA/TPRG/2PRG/U/-AO-SP2 [DIN] ), that option provides 5mA of excitation current to the 10 ohm RTD instead of the usual 0.25mA. This ensures that a robust input signal from the RTD to the SPA resists interference from the generator’s very strong electro-magnetic fields.

The choices available for a head mounted transmitter with similarly high current RTD excitation are limited. Bear in mind that the objective when designing RTD temperature transmitters is to reduce the excitation current as much as possible to minimize self-heating of the RTD, thereby maximizing the measurement accuracy.

Also due to the reduced power budget of loop powered transmitters there isn’t sufficient power available for the 5mA excitation current of the SP2 option.

A possible solution is one of our older analog loop powered transmitters, the RBX series, which has a relatively high excitation current of 1mA. The RBX, however, is a strictly analog design and must be specified according to the intended resistance range instead of temperature span. For example, for 10 ohm Cu and 0-200 deg C, the resistance is 9.035 to 16.776 ohms. The span is 7.741 ohms. The 7.741 span falls within the 3W5-10 input range.

The head mounted model number is: RBX/3W5-10/4-20MA/12-42DC/-EZ9 [BH2NS].

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Making Product Selection and Ordering Easier

Making Product Selection and Ordering Easier

In 2015 Moore Industries’ flagship product line, Temperature Assemblies and Sesors, was expanded with two new product families: the THZ3 and TDZ3 Dual-Input Smart HART Temperature Transmitters, and the newest member of the Functional Safety Series, the SIL 3 capable STZ Functional Safety Smart HART Temperature Transmitter with Dual Sensor Input. These new products meant we needed to update all of our temperature assemblies and sensors data sheets including the Ready-to-Install series, Assemblies for High-Tech, and the WORM Flexible Sensor. These newly improved data sheets give you all the information you need to more easily select and order the right product for your temperature application.

All of these data sheets include new temperature notations on WORM sensors and improved ordering information to make it easier to select and order.

RTI Ready-to-Install Temperature Transmitter Assemblies for both Head-Mount Transmitters and Hockey-Puck Transmitters have the THZ3, TDZ3 and the STZ added.

Hi-Tech Temperature Monitoring Solutions for High-Tech Facilities and Processes is completely redesigned with order info included on the page with each product. It features:

- Surface-Mount Air Duct Averaging Temperature Monitoring

- Duct-Mount Temperature Assembly for Monitoring Clean Rooms and Air Ducts

- Wall-Mount Room Air Temperature Monitoring

- Bath Calibration

- Humidity & Temperature Solutions

The WORM Flexible RTD and Thermocouple Sensors for Thermowell Temperature Assemblies and the CAN OF WORMS Economical 10-Pack of WORM Flexible Sensors features new Dual sensors and updated order information.

You can download any of these using the links above.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I need confirmation that the THZ2 is a functional like-for-like replacement for the THZ and that basically it will perform the same.

Q: I need confirmation that the THZ2 is a functional like-for-like replacement for the THZ and that basically it will perform the same.

A: With the exception of the THZ/PRG/4-20MA/12-42DC [DH2NG], which has an integral display, the THZ2 has all of the functions of the THZ and the same form and fit.

However, we suggest you consider the newer THZ3, since the THZ2 is being phased out (although it will continue to be available while supplies last). The THZ3 has all of the functions of the THZ2 and the same form and fit. The THZ3 offers additional functionality over the THZ2, can accept two sensor inputs, and utilizes PACTware for PC configuration in addition to HART programmability.

Other features found in the THZ3 that are not included in the THZ are:

- Backup and Fail-Over Protection allows either of the sensors or inputs to be designated as the primary measurement, with the secondary input acting as the backup sensor in case of primary sensor failure.

- Average and Differential Measurement allows you to average the two input measurements or select the differential (A-B or B-A) or absolute differential between the two inputs.

- High-Select and Low-Select Feature enables the transmitter to continuously monitor two separate inputs and designate either the highest or lowest input to represent the analog output.

- Dynamic Variable Mapping permits the user to assign either input or the calculated result of inputs to any of the four HART variables (PV, SV, TV or QV) that can be read by any HART compatible host system.

- Smart Range Alarms offer four HART alarms set to any input or calculated input that detect when the variable is within or outside user preset limits.

- High Availability Option enables the user to select how the AO behaves when there is an input failure or out-of-range value detected by the transmitter. This prevents nuisance alarms on startups or batch process shutdowns.

Download the THZ3 data sheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: You have a product called HART Interface Module that will pull the 2nd, 3rd and 4th HART variables from a smart HART transmitter and create one 4-20mA signal for each. Do you have or know of an instrument that will take three 4-20mA signals into it and place themdin on one 4-20mA signal as the 2nd, 3rd and 4th variable? I would like to read three transmitters on one 4-20mA signal by reading the variables on my DCS System.

Q: You have a product called HART Interface Module that will pull the 2nd, 3rd and 4th HART variables from a smart HART transmitter and create one 4-20mA signal for each. Do you have or know of an instrument that will take three 4-20mA signals into it and place themdin on one 4-20mA signal as the 2nd, 3rd and 4th variable? I would like to read three transmitters on one 4-20mA signal by reading the variables on my DCS System.

A: We have three products that can take multiple analog inputs and provide that signal data in the form of HART protocol. Those products are the TCM and THZ3 / TDZ3, which are temperature input devices that can take a 4-20mA input across a resistor (shunt) as a mV input.

The TCM is a 16-channel temperature input module that can be polled by a HART master using a device-specific HART command. This HART command retrieves all 16 channels of PV data in one HART message packet.

The THZ3 Dual Input Smart HART DIN-Rail or Field Mount Temperature transmitter can accept two (but not three) 4-20mA signals and write them to two of the HART dynamic variables riding on the analog 4-20mA output signal.

The TDZ3 has the same functionality as the THZ3 but includes a display and can be field mounted in hazardous or non-hazardous areas or mounted on DIN-Rail.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Moore Industries’ Functional Safety Line Card gives you all the information you need to know about our line of products for process safety-related applications. This includes our line of FS Functional Safety Series products designed and built to strict IEC 61508 standards, ensuring safe and reliable function – particularly in environments where hazardous or emergency situations are likely to occur.

Moore Industries’ Functional Safety Line Card gives you all the information you need to know about our line of products for process safety-related applications. This includes our line of FS Functional Safety Series products designed and built to strict IEC 61508 standards, ensuring safe and reliable function – particularly in environments where hazardous or emergency situations are likely to occur.

As with other Moore Industries line cards, the Functional Safety Line Card is available as a PDF download at our website. It gives an overview of the instrumentation that makes up our FS Functional Safety Series:

- STZFunctional Safety Dual Input Smart HART Temperature Transmitter

- SSX and SST Functional Safety Isolators and Splitter

- STA Functional Safety Trip Alarm

- SRM Functional Safety Relay Module

- SLD Functional Safety Programmable Display (2-Wire)

- SFY Functional Safety Frequency-to-DC Transmitter with Display

Along with the product information, the Functional Safety Line Card has valuable information for selecting the right Functional Safety instrument. The charts and safety-related information help determine whether instruments meet the required Safety Integrity Level (SIL) for use in a Safety Instrumented Function (SIF).

Q: I am looking to take a signal from an analyzer and send the analog output signal to four different locations. Do you have a product that can help me with this?

Q: I am looking to take a signal from an analyzer and send the analog output signal to four different locations. Do you have a product that can help me with this?

A: We offer a 4-channel output loop powered isolator and a line powered single input to dual output isolator.

If the receivers at the four locations can supply loop voltage to their respective 4-20mA inputs, then the 4-channel output loop powered MIX isolator (Model: MIX/4X4-20MA/4X4-20MA/12-42DC [DIN]) will work. Wire your 4-20mA signal in series to the four inputs of the MIX.

If the receivers at the four locations have passive (sinking) 4-20mA inputs, then you can either use two of the line powered ECT splitters or two of the dual channel MIT isolators (Models: ECT/4-20MA/2X420MA/117AC/-TX [DIN] or MIT / 2XPRG / 2X4-20mA / U [DIN]). Wire your 4-20mA signal in series to the inputs of the two ECT/MITs.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

A surge suppressor kit is now available for use in the BH and SB housings with our field transmitters. This easy to install and wire kit is approved for use in Explosion Proof applications in the United States/Canada (cCSAus) and Australia/New Zealand (ANZEx).

A surge suppressor kit is now available for use in the BH and SB housings with our field transmitters. This easy to install and wire kit is approved for use in Explosion Proof applications in the United States/Canada (cCSAus) and Australia/New Zealand (ANZEx).

Exceeding Severity Level 4 of 61000-4-4, the advanced surge suppressor provides 3kA(8/20μsec) of surge protection. Lightning-fast response time stops failures due to lightning, spikes, and overvoltage surges while minimizing other electrical noise. It can be used to suppress or protect both analog and HART digital/analog signal lines because of its ability to allow HART signals to pass through.

The surge suppressor works with many Moore Industries products including our temperature and signal transmitters, signal isolators and signal convertors. The kit is available as Part Number 205-863-12. Read the details in the data sheet available on the Surge Suppressor product page.

Do you want more information? Visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

The SIL 2/3 capable STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions by providing emergency shutdown or early warning indication in Safety Instrumented Systems (SIS).

The SIL 2/3 capable STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions by providing emergency shutdown or early warning indication in Safety Instrumented Systems (SIS).

In response to customer feedback, the STA has been updated to provide more flexibility in handling input faults. This allows for spurious alarms to be minimized and for alarms to be cleared without power cycling or needing physical access to the unit.

New configuration options that have been added include:

- Out-of-range input tolerances can now be set from 0-5%. There is a 2% restriction in use for safety systems.

- Startup delay from 0-120 seconds, which allows instruments providing input to the STA to stabilize on power up.

- Input fault alarms can now be non-latching or cleared remotely using the Manual Reset terminals.

For more information, please download the latest versions of the Data Sheet and Installation Manuals available at the STA product page.

Do you want more information? Download the data sheet. Or see the Functional Safety Solutions in the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Rob Stockham of Moore Industries-Europe delivered lectures earlier this month on the topic of “Producing High-Reliability Software for Instruments Used in Safety Applications.” The lectures covered the specifications, design, production and testing of firmware suitable for use in applications up to SIL 3 as defined by BS IEC 61508 Part 3.

Rob Stockham of Moore Industries-Europe delivered lectures earlier this month on the topic of “Producing High-Reliability Software for Instruments Used in Safety Applications.” The lectures covered the specifications, design, production and testing of firmware suitable for use in applications up to SIL 3 as defined by BS IEC 61508 Part 3.

The first lecture was to students at Liverpool John Moore’s University in the morning. This was followed up with an evening talk to the Central North-West Local Section of the Institute of Measurement & Control. A total of 39 people attended the two lectures.

“Thanks to Rob Stockham for presenting these lectures,” said Tom S. Nobles, Central North-West Programme Secretary for the Institute of Measurement & Control. “It’s particularly kind of him to lecture to the students. These young people represent potential future customers as well as people who need to interface with the industry and the measurement and control community in general. The attendance in the evening was also great, showing the interest and possible concern that users have about this subject.”

Rob said that he received positive interactions and feedback on the topic, although it was clear that more education is still needed on the topic. He was pleased that the EMPHASIS assessment tool and nuclear qualification of smart instruments were mentioned several times by lecture attendees.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I want to replace a THZ Temperature Transmitter (Model THZ/PRG/4-20MA/12-42DC [DIN]) with a CPT PC-Programmable Temperature Transmitter (Model CPT/TPRG/0-20MA/117AC/-C-RF [DIN]). The THZ unit we are replacing gets its power from the 4-20mA current loop while the CPT unit is going to be powered by 120Vac. Does the CPT need to be specified as "source" or "sink" to work as a drop-in replacement for the THZ unit?

Q: I want to replace a THZ Temperature Transmitter (Model THZ/PRG/4-20MA/12-42DC [DIN]) with a CPT PC-Programmable Temperature Transmitter (Model CPT/TPRG/0-20MA/117AC/-C-RF [DIN]). The THZ unit we are replacing gets its power from the 4-20mA current loop while the CPT unit is going to be powered by 120Vac. Does the CPT need to be specified as "source" or "sink" to work as a drop-in replacement for the THZ unit?

A: The default version of the CPT provides voltage on its output (source). If you would like the output to be passive so it can be wired to an active (voltage supplied) input, specify the "-SINK" option. The CPT will still require 120Vac power on the power terminals.

Note that the newer two-wire output loop powered THZ3 Dual Input Smart HART Temperature Transmitter (Model THZ3/PRG/4-20MA/12-42DC [DIN]) is now available.

Q: My concern is that we will damage the unit or the equipment it is connected to it if we specify the wrong type of output. This unit will be connected to an Allen Bradley 4-20mA analog input module. The previous THZ device got its power from the analog input module so I believe the correct specification would be "sink" for the CPT. Is this correct? Also, can the "source" or "sink" option be changed in the field or does this have to be set at the factory?

A: You are correct that you will need to choose the "-SINK" option on the CPT. The choice of "source" or "sink" for the CPT must be specified in the model number and supplied from the factory that way. It cannot be field changed. Your complete model number for this application would be: CPT/TPRG/0-20MA/117AC/-C-RF-SINK [DIN]. Note that you have also selected an auxiliary alarm contact and enhanced RFI/EMI protection.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

BPP Sales, Moore Industries' manufacturer’s representative for Louisiana and areas of southern Arkansas and Mississippi, held an Open House last month at their offices. We helped to make the event a big success by sponsoring the event and contributing one of the most popular prizes - a kayak with Moore Industries logo.

BPP Sales, Moore Industries' manufacturer’s representative for Louisiana and areas of southern Arkansas and Mississippi, held an Open House last month at their offices. We helped to make the event a big success by sponsoring the event and contributing one of the most popular prizes - a kayak with Moore Industries logo.

According to Regional Sales Manager Greg Feliks, several hundred people attended the event, which featured three bars, live music by the country group Parish-County Line and door prizes given away at the end of the night. Greg said that the kayak was one of the most popular items, with the emcee for the evening saying that Moore Industries "gets the Most Creative Giveaway Award." Greg even said that someone offered to buy the kayak from Marlene Bruce, the winner of the raffle, on the spot.

Moore Industries wants to help our manufacturer's reps with their events in any way possible. If you are a manufacturer's rep planning an event or tradeshow appearance and would like to partner with Moore Industries, contact your Regional Sales Manager.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Moore Industries had a very successful time at the Emerson Exchange show last week in Denver. According to Marketing Manager Tom Watson, a prime position next to Emerson’s “theater” helped to ensure a steady flow of traffic to the booth during the event.

Moore Industries had a very successful time at the Emerson Exchange show last week in Denver. According to Marketing Manager Tom Watson, a prime position next to Emerson’s “theater” helped to ensure a steady flow of traffic to the booth during the event.

“For the first day of the show on Monday, traffic to the Moore Industries booth was the heaviest that I have experienced in any previous Emerson Exchange,” Tom said. “It was non-stop with visitors from all over including Kuwait, Trinidad & Tobago, Argentina, Saudi Arabia, Peru, Ecuador, Chile and the US. Our booth was located right next to the Emerson ‘Theater’ at one end of the hall which had a steady stream of conference and exhibit attendees listening to a variety or presentations. In the Moore Industries booth, we talked with a wide spectrum of visitors from veteran Moore Industries customers to users who were unfamiliar with our company and products. There was significant interest in Fieldbus solutions from South American visitors, and several people asked about our HART and Functional Safety products.”

Moore Industries’ next event is the FieldComm Group’s FOUNDATION Fieldbus End User Seminar in Long Beach, CA on November 5. Registration is currently open for the show.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I need to use the STA Safety Trip Alarm in a hardwired panel. Is it possible to configure two different levels of alarm for each of two relays in the STA, in order to have two different trips (one for each relay)?

Q: I need to use the STA Safety Trip Alarm in a hardwired panel. Is it possible to configure two different levels of alarm for each of two relays in the STA, in order to have two different trips (one for each relay)?

A: Only one set point can be assigned to each alarm relay of the STA. However the dead-band is adjustable from 0% to 100% of the input span. Therefore you can specify one signal level at which the relay engages and another for when it disengages. If your input signal is 4-20mA, you can connect it in series to the inputs of two STAs in order to obtain 4 independent relay/setpoints.

Q: To clarify my situation: if I have a 0 to 100 bar transmitter, can I trigger Relay 1 at 25 bar and Relay 2 at 75 bar? We need to do this in order to shut down two different pieces of equipment at these pressure levels.

A: This is a typical function of the STA. One relay setpoint is often used for a warning at one level while the second relay setpoint is used for shutdown at the next level.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Moore Industries has updated our Temperature Solutions Line Card. Now available for digital download at our website, the line card reflects recent additions to our line of temperature-related products including the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters and the STZ Functional Safety Dual Input Smart HART Temperature Transmitter.

Moore Industries has updated our Temperature Solutions Line Card. Now available for digital download at our website, the line card reflects recent additions to our line of temperature-related products including the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters and the STZ Functional Safety Dual Input Smart HART Temperature Transmitter.

The line card has new information on the use of our temperature products in hazardous areas. The STZ and the STA Safety Trip Alarm are both SIL 3-capable, exida-approved products in our line of FS Functional Safety Series products. These products have been designed and built to strict IEC 61508 standards for use in a Safety Instrumented System (SIS), ensuring safe and reliable function – particularly in environments where hazardous or emergency situations are likely to occur. Other products in the FS Functional Safety Series are the SSX and SST Functional Safety Isolators and Splitter and the SRM Functional Safety Relay Module.

All of our product line cards are available for download at our website.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

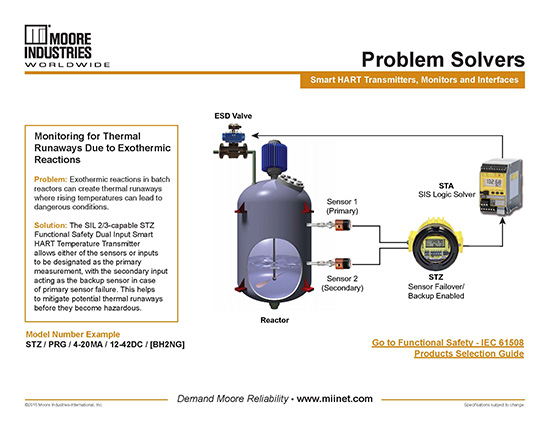

The SIL 3-capable STZ Functional Safety Dual Input Smart HART Temperature Transmitter has several features designed to reduce process interruptions safely in your SIS. One of the most important is the new dual sensor input that allows for Backup and Fail-Over Protection, which is the topic of a new Problem Solver on the Moore Industries website.

This example of a potential real-world application focuses on reducing the risk of exothermic reactions in batch reactors. These reactions can create thermal runaways where rising temperatures can lead to dangerous conditions. Backup and Fail-Over Protection allows either of the sensors or inputs to be designated as the primary measurement, with the secondary input acting as the backup sensor in case of primary sensor failure. This helps to mitigate potential thermal runaways before they become dangerous.

Visit the Problem Solvers section of our website to see more applications featuring the range of Moore Industries’ products.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

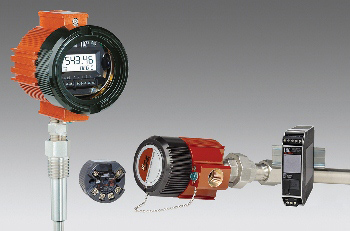

Moore Industries has released a video highlighting the features of our STZ Functional Safety Dual Input Smart HART Temperature Transmitter family. You can view the video at our Interface Solution Video Library or watch it below:

Part of the FS Functional Safety Series, the exida approved, SIL 3-capable STZ family provides an isolated and linear 4-20mA output proportional to the input with advanced features that give you far more control over your temperature measurements. This includes a dual sensor input that reduces process interruptions. Backup and Fail-Over Protection allows either of the sensors or inputs to be designated as the primary measurement, with the secondary input acting as the backup sensor in case of primary sensor failure. The dual sensor input also allows for Average and Differential measurements along with High-Select and Low-Select options.

The STZ family includes a wide range of housing options, all of which are shown in the product video. This is just one of the informative videos available for viewing at our Interface Solution Video Library. Along with videos highlighting product features, the library also includes videos showing real world examples of applications using our products.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We are in need of a signal converter that converts a 4-20mA logarithmic signal into a 4-20mA linear signal. We need one input and one output per device. Do any of your devices perform this function?

Q: We are in need of a signal converter that converts a 4-20mA logarithmic signal into a 4-20mA linear signal. We need one input and one output per device. Do any of your devices perform this function?

A: We offer several models of signal converters which have look-up table linearization/characterization capability.

The SIY is an output loop-powered unit that can be configured for up to 85 ordered pairs. With this model, each ordered pair must be keyed in using the provided configuration software.

The CPT is a line-powered model that can be configured for up to 128 ordered pairs. The ordered pairs are computed with a spreadsheet, saved as a two column CSV file and then loaded into the provided configuration software. The configuration is then loaded into the CPT.

With both models you specify the X and Y values so you can cluster points at the most non-linear part of your table.

With both models you specify the X and Y values so you can cluster points at the most non-linear part of your table.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We are a boiler/burner company dealing with a rising amount of computer-based burner controls. We have installed several and have some blowers that are controlled by VFDs (Variable Frequency Drives). We have run into issues with noise on certain systems. We get occasional problems with 4-20mA feedback from the VFD despite going through the proper grounding techniques. We are wondering if installing an opto isolator on the feedback loop might eliminate our issue. We have used the SIX Signal Isolator many times on the signal going to the VFD to offset impedance issues on the VFD. Can we put an opto isolator on both signals?

Q: We are a boiler/burner company dealing with a rising amount of computer-based burner controls. We have installed several and have some blowers that are controlled by VFDs (Variable Frequency Drives). We have run into issues with noise on certain systems. We get occasional problems with 4-20mA feedback from the VFD despite going through the proper grounding techniques. We are wondering if installing an opto isolator on the feedback loop might eliminate our issue. We have used the SIX Signal Isolator many times on the signal going to the VFD to offset impedance issues on the VFD. Can we put an opto isolator on both signals?

A: Whether the SIX or another isolator will cure your problem depends on the nature of the noise and how the loop is energized. Sometimes you can install an isolator without additional analysis and see if it works.

If you have data about the noise, compare it to the noise rejection specification of the isolator. For example, the Common Mode Rejection for the ECT-DIN Signal Isolator exceeds 95dB @ 60Hz with a limit of 1500 Vrms.

When selecting the appropriate isolator, take into account which device is providing the loop voltage on the input and output sides. Per the ECT datasheet, you can see that it is available as an output loop powered, input loop powered or line powered device.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Senior Sales Engineer JR Madden took the Moore Industries Instrumentation Trailer on the road to the Wyoming Oil and Gas Fair in Casper last month. He was able to get a prime “parking space” for the trailer as well – right between the main parking lot and the show entrance. It was a very popular show with an estimated attendance of 1,000. JR said that the attendees who stopped by the trailer were high-level employees interested in our instrumentation for the oil and natural gas industries.

Senior Sales Engineer JR Madden took the Moore Industries Instrumentation Trailer on the road to the Wyoming Oil and Gas Fair in Casper last month. He was able to get a prime “parking space” for the trailer as well – right between the main parking lot and the show entrance. It was a very popular show with an estimated attendance of 1,000. JR said that the attendees who stopped by the trailer were high-level employees interested in our instrumentation for the oil and natural gas industries.

Being able to set up shop outside of the show floor is an excellent advantage of having the Instrumentation Trailer. JR is able to get on the road and bring our range of instrumentation solutions to the public, both by attending trade shows and going on site to customers in conjunction with our reps.

Moore Industries will be at another big event next week as we will be one of the exhibitors at the Emerson Global Users Exchange 2015 from October 12-16 in Denver. If you are attending the show, make sure to stop by and see the latest instrumentation. We’ll be at Booth 212 next to the Integrated Operations section.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

The Moore Industries SIL 3-capable STZ Functional Safety Smart HART Temperature Transmitter family, part of the FS FUNCTIONAL SAFETY SERIES, is a dependable and accurate temperature transmitter for use in Safety Instrumented Systems (SIS) where dangerous processes occur. The STZ has been certified by exida after rigorous evaluation to ensure conformance with strict IEC 61508:2010 standards for safety-related applications.

The STZ offers a dual sensor input that reduces process interruptions. Backup and Fail-Over Protection allows either of the sensors or inputs to be designated as the primary measurement, with the secondary input acting as the backup sensor in case of primary sensor failure. The dual sensor input also allows

for Average and Differential measurements along with High-Select and Low-Select options.

The STZ also features Moore Industries’ Device Intelligence, a series of features designed for smarter control and monitoring including:

- Sensor drift and corrosion detection that checks and alerts users when the sensor is drifting out of a preset range or when the resistance due to corrosion exceeds set parameters.

- Smart range alarms with four HART alarms – set to any input or calculated input – that detect when the variable is within or outside of user preset limits.

- A High Availability option that enables the selection of how the AO behaves when there is an input failure or out-of-range value detected by the transmitter. This helps prevent spurious trips or nuisance alarms in Safety Instrumented Systems (SIS).

- Input simulation capability allowing manual input of a direct or calculated value. This essentially simulates a real input, allowing users to test the AO or any HART diagnostic and range alarms – which assists in proof test procedures.

The STZ is HART 7 compliant with exception-based reporting and dynamic variable mapping. It is HART and DTM programmable with user-oriented basic configuration for fast and accurate setup. Utilizing the HART DD, it can be configured and interrogated on the 4-20mA loop via any HART handheld communicator or HART compatible host. To prevent unauthorized or accidental reconfiguration of the STZ while it’s performing its safety function, it has an added security feature to allow users to set HART communication into a Read Only or Off mode. Users can also program or monitor the transmitter with any FDT compliant host or program such as PACTware using the STZ DTM.

The intrinsically-safe -AIS option for the STZ-DIN allows direct connection of sensors located in hazardous locations by including an embedded intrinsically-safe barrier in the front end of the STZ-DIN. The STZ-DIN -AIS is an associated apparatus suitable for mounting in Non-Hazardous or Class I, Division 2/Zone 2 hazardous locations with sensor input terminals connected to sensors or equipment in Class I, II, III, Division 1/Zone 0/1 hazardous locations.

See a video highlighting the key features of the STZ at our Interface Solution Video Library.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

The STA Safety Trip Alarm datasheet and installation manuals have been updated. The new change reflects the addition of a Universal power supply to the unit. Previously, customers needed to select either a 24DC or UAC power supply. The new Universal power supply accepts any power input range between 21.6-375Vdc or 90-260Vac.

The STA Safety Trip Alarm datasheet and installation manuals have been updated. The new change reflects the addition of a Universal power supply to the unit. Previously, customers needed to select either a 24DC or UAC power supply. The new Universal power supply accepts any power input range between 21.6-375Vdc or 90-260Vac.

Adding the Universal power supply option simplifies the ordering process for customers. In addition, it makes it easier for customers to plan additions or upgrades to their facilities without having to worry about the type of power being used.

The specifications in the datasheet and installation manuals have also been changed to reflect the new Universal power supply. Updated specs include Power Supply, Power Consumption and Alarm Trip Delay. In addition, the Relative Humidity specs have been updated.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

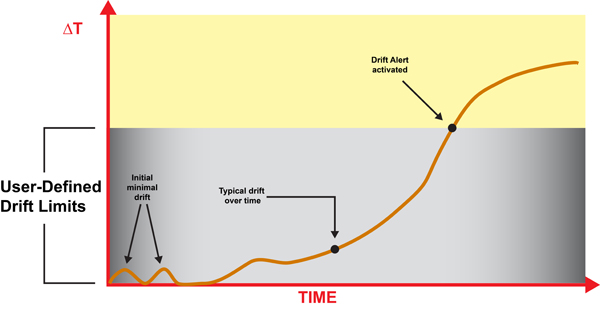

Sensor drift is a common problem that can lead to inaccurate temperature measurement readings. It can be caused by several factors including environmental contamination, vibration or extreme temperature fluctuations. Because this drift causes the measurement error to get worse over time, it’s not possible to calibrate out the error. Traditionally, reducing inaccurate measurements caused by sensor drift has meant undertaking a regular and time-consuming preventative maintenance calibration program.

You can avoid having to do constant preventative maintenance to avoid inaccurate temperature readings by using the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters. The Drift Alert feature lets you configure the transmitter to monitor the differential between the readings of the dual sensors. If the readings drift apart by an amount greater than your preset range, an out-of-range warning or alarm is triggered. This alerts plant engineers that maintenance is needed.

This sensor drift alert can be configured to send a drift alert via HART or you can drive AO to your preferred fail state.

If your BPCS does not have HART inputs cards, you can use the HIM Smart HART Loop Interface and Monitor to deliver the HART alarms and diagnostic data via relay contacts.

Interested in learning more tips for getting accurate temperature readings? Read our “A Practical Guide to Improving Temperature Measurement” white paper.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am looking for a device to create a temperature switch. I currently use a simple temperature switch with a 230°F setting, but at times the temperature of the unit goes over 400°F briefly and destroys the switch. I need to be able to hook a thermocouple up to the device and program a setpoint (with no display required) and have a set of dry contacts open when the temperature rises above the setpoint.

Q: I am looking for a device to create a temperature switch. I currently use a simple temperature switch with a 230°F setting, but at times the temperature of the unit goes over 400°F briefly and destroys the switch. I need to be able to hook a thermocouple up to the device and program a setpoint (with no display required) and have a set of dry contacts open when the temperature rises above the setpoint.

A: Our model CPA PC-Programmable Alarm can accept a thermocouple or RTD input and trip a relay based on the setpoint that you have configured. It can be configured using our software and a USB cable.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Moore Industries has integrated PACTware into the range of monitoring and configuration options available with products including the STZ Functional Safety Dual Input Smart HART Temperature Transmitter and the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters. Using an FDT host such as PACTware with a DTM is quickly becoming a worldwide standard as customers search for a universal method of programming, monitoring and diagnosing their field instruments. FDT/DTM technologies eliminate problems caused by vendors having different software programming packages or programming for multiple protocols (such as HART, FOUNDATION™ Fieldbus and PROFIBUS PA). Moore Industries has integrated PACTware into the range of monitoring and configuration options available with products including the STZ Functional Safety Dual Input Smart HART Temperature Transmitter and the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters. Using an FDT host such as PACTware with a DTM is quickly becoming a worldwide standard as customers search for a universal method of programming, monitoring and diagnosing their field instruments. FDT/DTM technologies eliminate problems caused by vendors having different software programming packages or programming for multiple protocols (such as HART, FOUNDATION™ Fieldbus and PROFIBUS PA).

Moore Industries has integrated PACTware into the range of monitoring and configuration options available with products including the STZ Functional Safety Dual Input Smart HART Temperature Transmitter and the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters. Using an FDT host such as PACTware with a DTM is quickly becoming a worldwide standard as customers search for a universal method of programming, monitoring and diagnosing their field instruments. FDT/DTM technologies eliminate problems caused by vendors having different software programming packages or programming for multiple protocols (such as HART, FOUNDATION™ Fieldbus and PROFIBUS PA). Moore Industries has integrated PACTware into the range of monitoring and configuration options available with products including the STZ Functional Safety Dual Input Smart HART Temperature Transmitter and the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters. Using an FDT host such as PACTware with a DTM is quickly becoming a worldwide standard as customers search for a universal method of programming, monitoring and diagnosing their field instruments. FDT/DTM technologies eliminate problems caused by vendors having different software programming packages or programming for multiple protocols (such as HART, FOUNDATION™ Fieldbus and PROFIBUS PA).

We’ve put together a single place for all the resources you’ll need to utilize PACTware. You can visit our PACTware Resource Center to get all the downloads and information you’ll need to set up and configure your instruments or to perform monitoring and diagnostic capabilities.

This includes:

PACTware Configuration Software and DTMsDevice DTMsMISP Comm DTMWhile on the resource page, you can also view a tutorial highlighting the basics of PACTware by Moore Industries Director of Customer Service Bob Croughwell.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Part of the Moore Industries FS FUNCTIONAL SAFETY SERIES, the exida® SIL 2 and SIL 3 certified STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions; warns of unwanted process conditions; provides emergency shutdown; or provides on/off control in Safety Instrumented Systems (SIS) and traditional alarm trip applications.

Part of the Moore Industries FS FUNCTIONAL SAFETY SERIES, the exida® SIL 2 and SIL 3 certified STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions; warns of unwanted process conditions; provides emergency shutdown; or provides on/off control in Safety Instrumented Systems (SIS) and traditional alarm trip applications.

The 4-wire (line/mains-powered) STA models accept a signal input from transmitters, temperature sensors and a wide array of other monitoring and control instruments including:

- Current and Voltage Signals

- Temperature (RTD and T/C) Sensor Inputs

- Resistance and Potentiometer Devices

- Direct Millivolt Sources

Do you want more information? Download the data sheet. Or visit the catalog.

Check out the STA Safety Trip Alarm

Need to get price or availability or have a technical question?

Send us a message using E-Help.

The STZ is the latest in the line of Moore Industries' Associated Intrinsically-Safe (AIS) family of products. The SIL 2/3 capable STZ Functional Safety Dual Input Smart HART® DIN-style Temperature Transmitter with Associated IS sensor connections are certified by exida to IEC61508 for systematic integrity up to SIL 3 and for single use in Safety Instrumented Systems (SIS) up to SIL 2.

The STZ is the latest in the line of Moore Industries' Associated Intrinsically-Safe (AIS) family of products. The SIL 2/3 capable STZ Functional Safety Dual Input Smart HART® DIN-style Temperature Transmitter with Associated IS sensor connections are certified by exida to IEC61508 for systematic integrity up to SIL 3 and for single use in Safety Instrumented Systems (SIS) up to SIL 2.

The intrinsically-safe -AIS option for the STZ-DIN allows direct connection of sensors located in hazardous locations by including an embedded intrinsically-safe barrier in the front end of the STZ-DIN. The STZ-DIN -AIS is an associated apparatus suitable for mounting in Non-Hazardous or Class I, Division 2/Zone 2 hazardous locations with sensor input terminals connected to sensors or equipment in Class I, II, III, Division 1/Zone 0/1 hazardous locations.

The STZ-DIN configures quickly and easily to accept a single or dual input from a wide array of sensors and analog devices including RTDs, thermocouples, resistance and potentiometer devices, and direct millivolt inputs. The STZ-DIN’s 2-wire (loop-powered) Associated IS transmitter provides an isolated and linear 4-20mA output proportional to the input. This signal is ready for direct interface with a HART or non-HART based Safety System, DCS, PLC, and other SCADA systems.

The STZ is HART and DTM Programmable with user-oriented basic configuration for fast and accurate setup. The STZ-DIN provides HART exception-based reporting and dynamic variable mapping as well as HART Access Control, which allows users to set HART communication to Read Only or Off mode, to prevent unauthorized or accidental reconfiguration while it is performing its safety function.

Check out Moore Industries other Associated Intrinsically Safe products including the newly released THZ3 -AIS Dual Input Smart HART® Temperature Transmitter with the -AIS option for the DIN Rail Mount housing and the reliable universal SPA2IS Programmable Limit Alarm Trip. All these feature the rugged reliability customers have come to rely on from Moore Industries. With these Associated Intrinsically-Safe products there is no need for the additional cost of the IS barrier, cabinet space, high integrity clean ground connection, separate power supply, or custom vendor backplanes. This drastically reduces the cost of purchasing, installation, and maintenance versus more traditional approaches requiring a separate Zener or isolating barrier.

Learn more about the STZ with -AIS, THZ3 with -AIS, and the SPA2IS from our website.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Hydrocarbon Processing, October 2007

For about 30 years, it has been a given within the oil and gas industry that intrinsic safety (IS) is the natural technique for explosion-proof protection of electronic instruments. Fieldbus users now want complex processing and digital communications to and from many devices in intrinsically safe applications. The key is delivering enough power to a large number of field devices.

View Article (PDF, 1.9M )

Control Supplement, September 2009

The HART protocol is simple, easy to understand and use, yet powerful and reliable. The HART protocol has become an industry-leading communications technology. Now that HART device use is commonplace and continues to grow, achieving interoperability is the goal of the HART device registration process. Moore Industries looks to lead the way in developing HART 7 technology. Scott Saunders, Vice President at Moore Industries, comments on the new features that will be implemented as part of the HART 7 standard.

View Article (PDF, 1.9M )

Control Engineering, December 2009

Technological advancements such as systems on a chip, multi-core processing and higher levels of integration have led to devices that are smaller, lighter, faster and smarter. These smart devices are bringing industrial applications into a realm of unprecedented product and system performance and efficiency. Building intelligence into devices has also driven diagnostics to the component level. Thus, information from such smart devices must be easily accessible and understood.

Moore Industries Director of Technology Charles Larson discusses the improvements in the software of smart devices that lends to component reliability; even allowing smart instruments to be used in safety applications. Intelligence at the Device features Moore Industries microprocessor-based THZ2 Temperature Transmitter as an example of a smart device with advanced sensing and diagnostic capabilities.

View Article (PDF, 1.2M )

Process Industry Informer, January/February/March/April 2008

Don't get hung up on which fieldbus to choose. Fieldbus is a generic term for a variety of communications protocols using various media, but all are simply a means to an end. What you want at the end of the project is a satisfactory and functional control system. Although Fieldbus is a wonderful technology with many benefits, its installation requires considerations over and above typical 4-20 mA projects. In parts 1 and 2 of this article, MooreHawke fieldbus expert Mike O'Neill discusses how to specify fieldbus power supplies; make segment calculations; implement fieldbus segment termination; select fieldbus cable and wiring and more.

View Article (PDF, 3.0M )

IPP&T Magazine, October 2006

Process plants often have certain locations where explosive or flammable gases and vapors may exist through accidental or unavoidable release. One of our fieldbus experts, Harry Wilson, addresses the various techniques-including Entity vs. FISCO-used in hazardous area installation of fieldbus devices.

View Article (PDF, 1.5M)

Industrial Networking Magazine, April 2005

Mesh networks restore broken links, enhance reliability and show potential for success in control applications. In this comprehensive article, industry experts, including Moore Industries' Scott Saunders, discuss how this emerging network strategy can be implemented.

View Article (PDF, 2.0M)

Control Supplement, September 2011

Moore Industries Director of Engineering Tina Lockhart was quoted in the Control Global 2011 HART Supplement. In the article, she discusses the advantages of utilizing information stored within HART field devices, including the ability to quickly get diagnostic information and the reduction in maintenance costs and disruptions.

View Article (PDF, 900K)

HART LINE Newsletter, September 2000

Estimates indicate that as much as 40 to 50 percent of loop operational problems can be blamed on final control elements. In this technical article, our Director of Professional Development Bud Adler tells how HART communicating valve positioners used in conjunction with HART loop monitors provide an efficient and cost-effective way to test online emergency shutdown valves and increase system integrity.

View Article (PDF, 136K)

HART Communication News, July 2005

The HART Protocol's bi-directional, digital communication capability has given the technology a vital role in testing of safety instrumented systems that protect people, the plants they work in and the environment. Read this article to learn more.

View Article (PDF, 240K)

HART Communication Foundation, October 2004

The HART Communication Foundation (HCF) announced at ISA Expo 2004 that the BP Cooper River Plant in Wando, South Carolina has been selected as one of two recipients of its 2004 HART Plant of the Year Award. The award is given annually to recognize success in the innovative use of HART communications in real-time process applications. A major component of BP Cooper River Plant's winning application includes the use of the Smart HART Loop Interface and Monitor (Model HIM) from Moore Industries.

Applied Automation, May 2008

A simple and cost-effective solution for gathering HART information is to use a HART interface device. Fortunately, HART interface devices make acquiring HART data a fairly simple proposition. Moore Industries Greg Feliks tells how.

View Article (PDF, 1.3M )

HART Communication Foundation, November 2004

Featured in this issue of the HARTLINE newsletter, our HIM HART Loop Monitor now has the ability to confirm that the Fisher® FIELDVUE® DVC6000 Series Digital Valve Controller is performing a partial valve stroke test and, if the test has failed, to alert the user that the ESD valve is stuck.

View Article (PDF, 107K)

IAN Magazine, September 2005

Our new HCS HART Concentrator System earned EXCELLENCE IN AUTOMATION distinction in IAN magazine. The HCS is the simple answer when you need to link smart HART instruments and transmitters with MODBUS-based monitoring and control systems.

View Article (PDF, 122K)

ISA Sensors Technology, September 2001

Even though precise temperature management is crucial to a myriad of applications, "Hundreds of interviews with plant personnel have made it clear to me that most users believe they are making a better temperature measurement than they actually are," said Bud Adler, our Director of Professional Development. In this article, Bud discusses important strategies to improve your overall temperature measurements.

View Article (PDF, 1.0M)

Industrial Networking Magazine, July 2004

What is your definition of a robust industrial network? How about a network that is reliable, immune to industrial noise and environmental issues, secure, and keeps working no matter what? In this article written by Senior Technical Editor Rich Merritt, industry experts, including Moore Industries' Scott Saunders, discuss the practical issues of creating a reliable industrial I/O network.

View Article (PDF, 2.3M)

Control Solutions Magazine, September 2001

Manufacturers will certainly consider widely applying digital fieldbus transmitters and control devices in new plants and for major retrofits. However, given today's money-tight, manpower-short conditions, it is unreasonable to expect users to spend the dollars required to implement a wholesale, field-level instrument retrofit to accommodate new digitally communicating instruments. In this article, our Vice President of Engineering Joe Hage discusses ways to use HART Loop Monitors to "unlock the hidden secrets" of in-place legacy instruments and achieve similar process improvements and diagnostic capabilities as would be available with all-digital strategies.

View Article (PDF, 897K)

Control Engineering Europe, April 2011

Charles Larson of Moore Industries was quoted in the HARTline Newsletter in a story discussing the benefits of HART 7. Larson mentioned that the introduction of HART 7 has "improved the ability of additional data and diagnostic information from devices" along with increasing "the awareness of users to the wealth of information in HART devices that can be used in plant efficiency."

To learn more about our link of Smart HART® loop monitors and interfaces, please visit our selection index.

View Article (PDF, 520K)

Compliance Engineering Magazine, May 2003

With IEC 61508, manufacturers can ensure the functional safety of all aspects of a product's life cycle. In this technical article, Moolifecycleies' Kristina L. Balobeck discusses emerging safety standard IEC 61508. Entitled Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems, the new standard encompasses all aspects of a products conceptualization, development, manufacturing, and testing of its components.

View Article (PDF, 1.0M)

IAN Magazine, October 2002

We were honored in the special 50th Anniversary issue of IAN magazine with an article chronicling some highlights of our company's history. The article takes a look at innovations introduced during our tenure in process control by comparing industry, and company, progressions with whimsical and interesting happenings of the time. It's a fun read.

View Article (PDF, 556K)

Canadian Process Equipment and Control News, August 2002

"A major challenge that faces natural gas extraction and transport applications is that they are often located in extremely remote locations. Natural gas gathering stations, compressor stations, pipeline feed applications and booster stations all involve the operation of pneumatic control valve actuators that require a pneumatic supply for operation", states Gus H. Elias, our Senior Certifications Engineer. In this article, Gus discusses the use of natural gas as a pneumatic supply in applications where it is impractical or impossible to supply instrument air for valve actuation.

View Article (PDF, 882K)

Control Engineering-Europe Magazine, June 2006

Until now, the only ways to protect plant-critical segments were expensive duplication of an entire segment's hardware, complex software voting schemes, and restricting the number of devices per segment. Our new TRUNKSAFE Fault Tolerant Fieldbus System provides a cost-effective and simple strategy to eliminate this shortfall.

View Article (PDF, 434K)

WNIPT, February 2015

According to the FieldComm Group (formerly the HART Communications Foundation), there are more than 30 million HART-enabled instruments installed in chemical and process plants worldwide, and most process transmitters made today are HART compatible. The HART digital signal often contains valuable process measurements and other variables including instrument status, diagnostic data, alarms, calibration values and alert messages.

However, many systems fail to utilize the critical information available from HART-enabled transmitters, valve positioners, flowmeters and other "smart" devices. This article shows how a HART interface device can serve as a simple and cost-effective solution for gathering HART information.

View Article (PDF, 4.25M)

Control Solutions Magazine, July 2003

Our NCS NET Concentrator® System was featured on the cover and in a special Product Feature in this issue of Control Solutions magazine. Drawing on our 35 years experience in precision transmitter technology, the NCS provides exceptional 20-bit measurement resolution (in contrast to 12-, 14- or 16-bit for comparable I/O systems) and signal conditioning capabilities equivalent to the highest-quality transmitters on the market.

View Article (PDF, 892K)

Control Engineering, March 2009

While extending Ethernet to a PLC or DCS I/O block is very common, the idea of using it to connect to individual process or discrete sensing devices is relatively rare. But is that assessment changing? In this article, Control Engineering magazine's Peter Welander discusses the role of Ethernet based instrumentation in device-level networks.

View Article (PDF, 1.5M )

Engineering and Technology, February 2009

Rob Stockham, our Moore Industries-Europe General Manager and safety expert, look at the latest method being employed by the UK nuclear industry to access control systems in safety-related and safety-critical applications in power stations.

View Article (PDF, 1.6M )

Fieldbus Report, October 2008

Modern DCS systems are major distributed networks with multiple data paths, which, in the interests of security and the highest plant availability, are almost always duplicated and made redundant. This article describes how FOUNDATION fieldbus systems can now incorporate redundancy and fault-tolerance right down to the H1 field layer. The major impact is on project ROI and plant revenues, and only FOUNDATION technology can offer this level of security and benefit to the plant operator.

View Article (PDF, 518K )

Canadian Process Equipment and Control News, December 2000

Our universal temperature transmitters have made front-page news in Canada once again. This time it's the brand-new dual-compartment version of our THZ Smart HART Temperature Transmitter. In addition to amazing accuracy and stability specifications, the THZ comes standard with a process display that shows the real-time temperature reading and the 4-20mA output value. To save you time and money, the THZ transmitter can be ordered as a fully tested, ready-to-install assembly that includes sensor, thermowell. All you have to do is install it into your process, connect a couple of loop wires, and you're in business.

View Article (PDF, 222K)

IAN Magazine, October 2006

Our TG200 TRUNKGUARD® Series Device Coupler earned an Excellence in Automation award for its patented Automatic Segment Termination and unique spur short circuit protection.

View Article (PDF, 593K)

Process Industry News, June/July 2008

One of the new minefields for a product manager is the mandatory European Community (IEC) Harmonised Safety Compliance Directives and Standards, with the most current ATEX directive 94/9/EC. ATEX standard for "Atmosphere Explosives", and it is the law in the EU since July 2003. In this informative technical article, Moore Industries Senior Certifications Engineer Gus Elias helps you negotiate the maze of national and international rules and regulations associated with ATEX.

View Article (PDF, 103K )

HART LINE Newsletter, February 2001

Despite the reliability delivered by today's process transmitters and valve controllers, devices do fail. The more risk associated with a failure, the more important it is to ensure the operational integrity of the device. Our Director of Professional Development, Bud Adler, describes how to use HART Loop Monitors to provide continuous fault loop monitoring and increase plant safety.

View Article (PDF, 487K)

Control Supplement, September 2009

Approximately 80 percent of the Smart HART device population is underutilized, as plants rely on the smart technology only once or twice a year for setup and calibration. Automation professionals can no longer afford to do this. This article explains the simple and easy ways to get the valuable HART device information out into the plant and into the hands of end users to improve plant operations.

"Connecting the HART to the Rest of the Plant," features Moore Industries HIM Smart HART Loop Interface and Monitor that "breaks out" HART data.

View Article (PDF, 2.7M )

Process Heating Magazine, September 2005