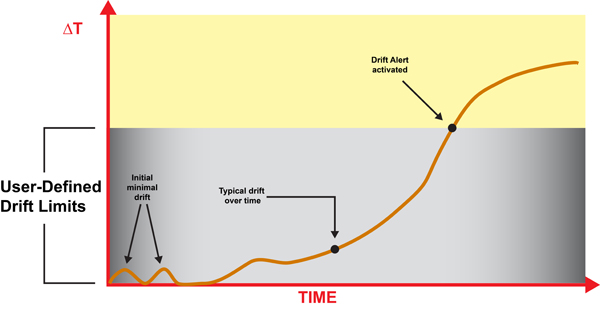

Sensor drift is a common problem that can lead to inaccurate temperature measurement readings. It can be caused by several factors including environmental contamination, vibration or extreme temperature fluctuations. Because this drift causes the measurement error to get worse over time, it’s not possible to calibrate out the error. Traditionally, reducing inaccurate measurements caused by sensor drift has meant undertaking a regular and time-consuming preventative maintenance calibration program.

You can avoid having to do constant preventative maintenance to avoid inaccurate temperature readings by using the THZ3 and TDZ3 Dual Input Smart HART Temperature Transmitters. The Drift Alert feature lets you configure the transmitter to monitor the differential between the readings of the dual sensors. If the readings drift apart by an amount greater than your preset range, an out-of-range warning or alarm is triggered. This alerts plant engineers that maintenance is needed.

This sensor drift alert can be configured to send a drift alert via HART or you can drive AO to your preferred fail state.

If your BPCS does not have HART inputs cards, you can use the HIM Smart HART Loop Interface and Monitor to deliver the HART alarms and diagnostic data via relay contacts.

Interested in learning more tips for getting accurate temperature readings? Read our “A Practical Guide to Improving Temperature Measurement” white paper.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.