Q: How can I take a HART Primary Variable (PV) from an oxygen transmitter (with only one HART output available), and output two identical analog signals?

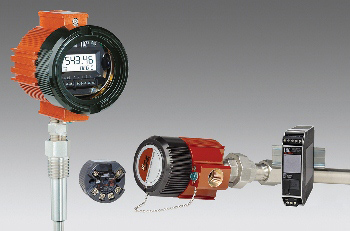

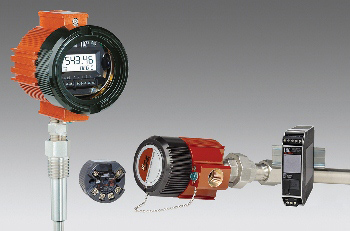

A: Here are two approaches you can use by utilizing Moore Industries SST HART Functional Safety Isolator and Splitter or the HIM HART Loop Interface and Monitor.

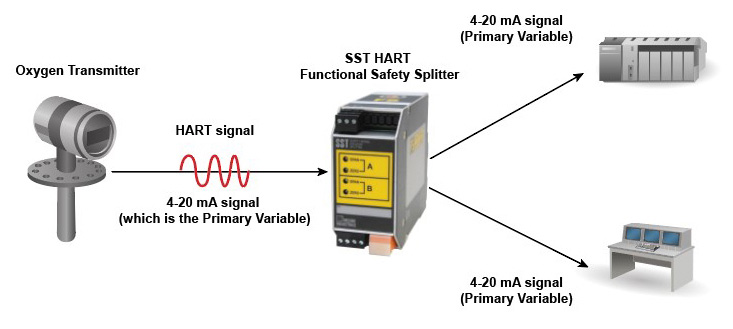

SST Splitter Solution:

Since the oxygen transmitter has a HART output, we know that this particular output is a 4-20mA signal plus the HART digital signal. We also know that the 4-20mA signal is the HART Primary Variable. Therefore you can wire your oxygen transmitter to the SST Splitter to split the 4-20mA signal and send it to your two destinations as a 4-20mA signal. This is the less expensive approach. The SST solution could also send the HART digital signal to both destinations, if that had value to the user.

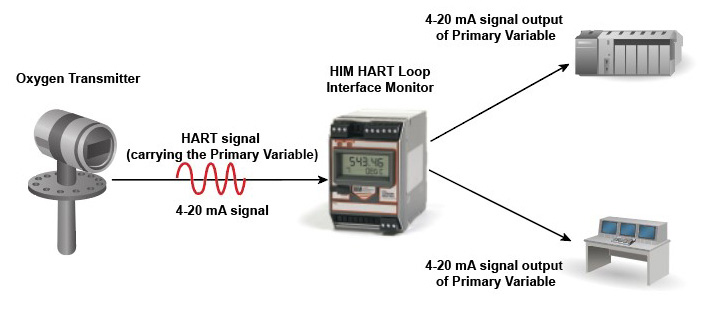

HIM Solution:

Since the O2 transmitter HART output digital signal also contains the Primary Variable, you can wire your oxygen transmitter to the input of the HIM. The HIM will read all the HART Dynamic Variables, but we will assign the Primary Variable to two HIM 4-20mA outputs which go to the two destinations. The HART digital signal does not get passed to the HIM analog outputs.

While this is the more expensive strategy, it does offer significantly more flexibility in your system. The HIM can send up to three analog output signals, as opposed to just splitting an analog signal in two; these analog signals can all be the same Primary Variable, or they could be the Second, Third, or Fourth Variables, which are also contained within your oxygen transmitter’s HART output signal. In addition, the HIM can provide you with two relays for Process or Diagnostic alarming and has a large 5-digit display for ease of use. Because the HIM is a configurable device it can easily be repurposed in the future.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. What is the purpose of increasing input resistance to 250 ohms with the IZ250 option on the Moore Industries SSX signal isolator/repeater?  A. If you anticipate that the total loop resistance where your HART transmitter resides will be lower than 230 Ohms, this option will ensure you have enough impedance in the loop to create a sufficient voltage drop for reading the HART signal by a HART host (handheld or input card). The HART digital specification requires the loop to have total loop impedance between 230 and 1100 Ohms in order to initiate and maintain stable communication with HART devices.

A. If you anticipate that the total loop resistance where your HART transmitter resides will be lower than 230 Ohms, this option will ensure you have enough impedance in the loop to create a sufficient voltage drop for reading the HART signal by a HART host (handheld or input card). The HART digital specification requires the loop to have total loop impedance between 230 and 1100 Ohms in order to initiate and maintain stable communication with HART devices.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: A field tech told me he installed an IPT2/4-20MA/3-15PSIG/20PSIG/-FA1 [DIN] unit. In the product bulletin, I don't see a purpose for the trailing "2" in the model name, and I don't see an explanation for -FA1.

Q: A field tech told me he installed an IPT2/4-20MA/3-15PSIG/20PSIG/-FA1 [DIN] unit. In the product bulletin, I don't see a purpose for the trailing "2" in the model name, and I don't see an explanation for -FA1.

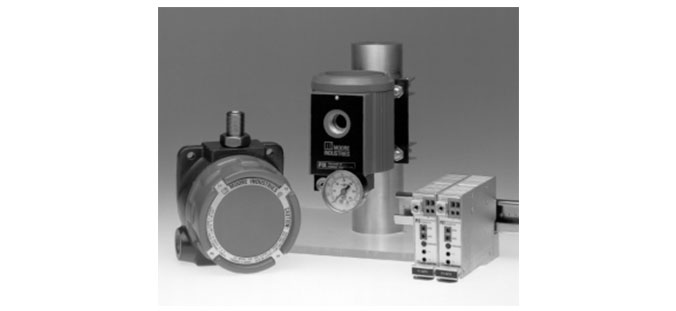

A: The “2” in IPT2 indicates that it is the successor to the older IPT. It is a direct replacement with the same form/fit/function with improved performance. This next-generation IPT2 I/P Transmitter provides advanced features including 18 standard pressure output ranges, lower air consumption, quick response to step changes, greater accuracy, drift reduction, and more.

The -FA1 option provides a mounting block for the installation of the unit on DIN rail. It also designates that the supply and outlet ports are on the bottom of the mounting block, the electrical signal test jacks, and electrical connections are on the front face and that there is no pneumatic test jack. (see table 2 on page 3 of the data sheet for the explanation.)

Do you want more information? Visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We are considering ordering the Moore Industries SPA/0-100mV/2 PRG/U/-SOL [DIN]. Can we power it using 24VDC? If so, what is the power consumption and how do we terminate? Also, can you please confirm whether this unit is Class 1 Div2, group A,B,C,D?

Q: We are considering ordering the Moore Industries SPA/0-100mV/2 PRG/U/-SOL [DIN]. Can we power it using 24VDC? If so, what is the power consumption and how do we terminate? Also, can you please confirm whether this unit is Class 1 Div2, group A,B,C,D?

A: The SPA can be powered with 24VDC. It accepts any source voltage in the ranges of 22-300Vdc or 90-260Vac. Power Consumption is 2-4W, nominal; 6W, maximum.

If you specify the -HS option (hermetically sealed relays) then it is approved for Class 1 Division 2 locations when installed in an enclosure that provides sufficient mechanical and environmental protection. Usually, a NEMA 4 rated box will serve. See page 1 of the data sheet (click the link to open the download page).

The sample model number with -HS option and with a NEMA 4 enclosure is:

SPA/0-120MV/2PRG/U/-SOL-HS [R3H].

The –SOL option in this model number indicates a specially engineered SPA used to monitor the health of solenoid valve coils.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: What are some ways to improve the long-term stability of my RTD temperature measurement?

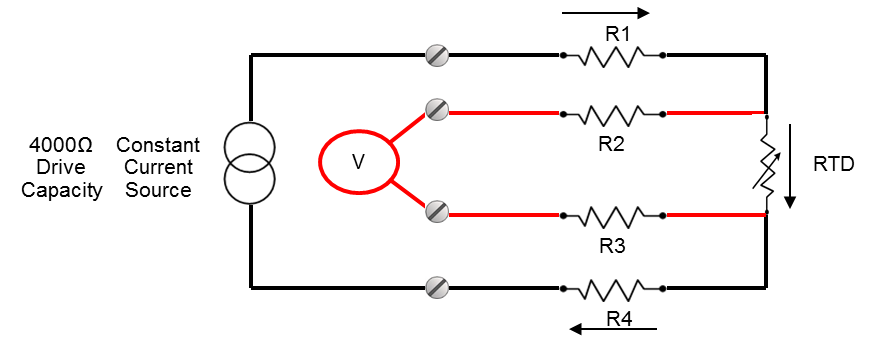

A: There's no question that the first step in improving the overall quality and long-term stability of your temperature readouts is to use a Class A, 4-wire RTD. Lead wire imbalances are a major cause of instability during the measurement process. A single ohm of imbalance in a three wire, platinum .00385 alpha, 100 ohm RTD can produce as much as 2.5°C of error in a measurement. By adding a fourth lead wire, you eliminate potential errors in measurements created by resistance imbalances between leads. 4-wire RTDs are no longer just for special uses, and they aren't cost-prohibitive. In fact, in many cases they are more cost-effective than using traditional 3-wire RTDs.

Another way to improve long-term stability is to make sure that your RTDs have been thermally aged. This process involves placing RTDs into a continual cycle of temperature extremes that season the RTD and even help extend its measurement life. The sensors that we use in high-accuracy applications have been temperature cycled from 0°C to 600°C for 1,000 hours, making them virtually drift-free for the next five to 10 years.

Do you want more information? Find a data sheet here. Or see our Temperature Transmitters or Temperature Assemblies and Sensors.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

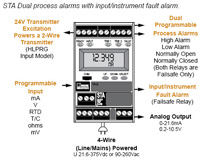

Q: For the STA 4-Wire SIL 2 and SIL 3 Compliant Programmable Current/Voltage and RTD/Thermocouple Safety Trip Alarms, can the process alarm relays be configured as Failsafe? Can the process relay output of the SPA2-TRPRG be configured Failsafe?

Q: For the STA 4-Wire SIL 2 and SIL 3 Compliant Programmable Current/Voltage and RTD/Thermocouple Safety Trip Alarms, can the process alarm relays be configured as Failsafe? Can the process relay output of the SPA2-TRPRG be configured Failsafe?

A: The output relays of the STA are configured only as Failsafe. For example, the coils are de-energized in the alarm condition or when there is a loss in power. For systematic integrity up to SIL 3 and for random integrity up to SIL 2, the STA is also exida certified 61508:2010. This means that an STA is approved for single use in Safety Instrumented Systems (SIS) up to SIL 2 and in redundant architectures (1oo2, 2oo3, etc.) up to SIL 3.

The output relays of other alarms that we offer such as the SPA2 can be configured either as Failsafe or Non-Failsafe.

Download the SPA2 or STA data sheet for more details.

Q: Does your SPA2 have a SIL 2 rating?

Q: Does your SPA2 have a SIL 2 rating?

A: The SPA2 can be used in safety instrumented systems (SIS) as long as the appropriate safety-related data and restrictions in use are reviewed and followed by a competent safety practitioner. We have a FMEDA (Failure Modes, Effects and Diagnostics Analysis) report that provides this data for the SPA2, and is available upon request.

We also offer the STA Functional Safety Limit Alarm Trip, which is expressly designed for safety related applications and has third party certification (exida) per IEC 61508:2010 for systematic integrity up to SIL 3 and for random integrity up to SIL 2.

The exida certified FMEDA data can be provided and used by a competent functional safety practitioner to calculate the required PFDavg and determine the SPA2s or STAs SIL capability and overall suitability in your Safety Instrumented Systems (SIS).

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am looking for a signal conditioner that has multiple inputs (RTD) that can be averaged on one mA output. What do you recommend?

Q: I am looking for a signal conditioner that has multiple inputs (RTD) that can be averaged on one mA output. What do you recommend?

A: First determine how many RTDs you need to average, the number of wires (2-wire, 3-wire, or 4-wire), and are the cable lengths the same for each RTD? Then we can help you determine which product will fulfill your specific needs.

Moore Industries has several products that can handle multiple RTD inputs and provide a calculated average output.

Both field-mount and Din-mount models are offered. The THZ3/TDZ3 models handle two RTD inputs while the SPT, MDS and NCS handle three or more RTD inputs. If you have an application that involves Safety Instrumented Systems (SIS), the STZ transmitter family can be used.

The THZ3 is a smart HART two-wire, output loop powered transmitter that comes in a hockey puck configuration for field mount applications or in a DIN rail mount package for cabinet installations. The TDZ3 is a field mount unit with an integral display. Both units offer the ability to output a 4-20mA signal that represents the average of the RTD inputs.

The SPT accepts T/C, RTD, millivolt, or ohms input in different ranges, sensor types, and connection schemes. The SPT has a simple menu system and LCD screen for easy setup and calibration, and all settings are stored in non-volatile memory, protecting them from power loss.

The SPT accepts T/C, RTD, millivolt, or ohms input in different ranges, sensor types, and connection schemes. The SPT has a simple menu system and LCD screen for easy setup and calibration, and all settings are stored in non-volatile memory, protecting them from power loss.

The I/O Equation Station Multifunction Distributed I/O System (MDS) is a four-wire module that can average up to 4 RTDs. The number of wires per RTD depends on the number of RTDs that can be connected.

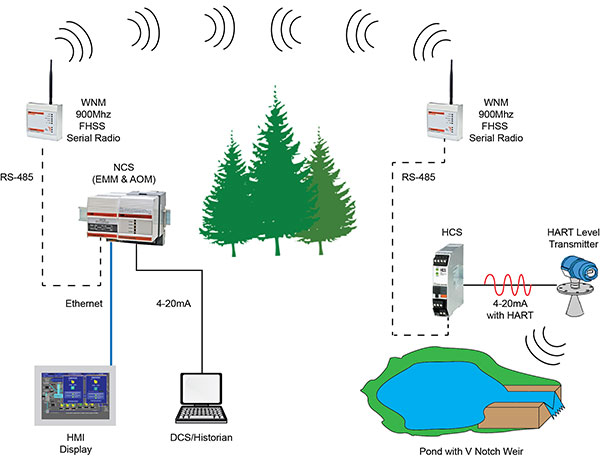

The Net Concentrator System (NCS) is an expandable I/O system that consists of input and output modules that can be configured to accept any number of RTD inputs to calculate an average output. The NCS can be programmed to handle a wide range of signal input and output including current, voltage, discreet, relay, RTD, thermocouple, resistance, and potentiometer with an operating range of -40°C to +85°C.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

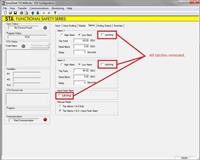

Q: We do not have sufficient PLC digital output spares to perform a Manual Reset of the three installed safety temperature controllers. We are going to remove the alarm latching on both limits and faults on our STA Functional Safety Alarm Trip. The Manual Reset radio button stays active in the STA configuration software. Will the latches clear after we are outside the dead band limits?

Q: We do not have sufficient PLC digital output spares to perform a Manual Reset of the three installed safety temperature controllers. We are going to remove the alarm latching on both limits and faults on our STA Functional Safety Alarm Trip. The Manual Reset radio button stays active in the STA configuration software. Will the latches clear after we are outside the dead band limits?

A: The radio buttons selected in the Manual Reset rectangle are irrelevant if you have not checked any of the Latching check boxes in the Display Alarms tab. Therefore, if latching is unchecked, the alarm state will reset once normal conditions exist after a brief event.

When using the configuration software, settings are downloaded to the instrument in the form of a Configuration File and stored in the instrument’s memory. You can save a backup copy of the file on your PC hard drive. The STA communicates with the PC through an RS-232 connection to the PC’s serial port or optional USB Communications Cable. Learn more about the STA Functional Safety Alarm Trip.

Q. What are the advantages and limitations of HART protocol or an instrument with MODBUS communication embedded? How many instruments can the HCS interface in the same loop? Are we able to read/write the five instruments at the same time using HART?

Q. What are the advantages and limitations of HART protocol or an instrument with MODBUS communication embedded? How many instruments can the HCS interface in the same loop? Are we able to read/write the five instruments at the same time using HART?

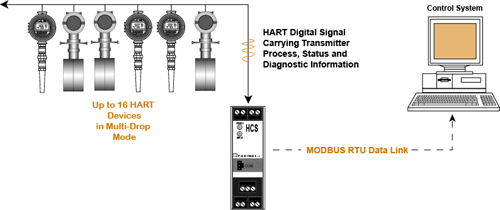

A. Today, a major advantage that HART and MODBUS RTU possess is industry- wide acceptance by users and manufacturers. HART-enabled transmitters, valve positioners, flowmeters, and other smart devices superimpose a digital signal upon their 4-20mA process signal. Combining digital communications with the 4-20mA DC signal provides flexibility of application for process control instrumentation and accommodates multiple variables and device self-diagnostics. HART field transmitters measure process parameters as well as generating a 4-20mA signal used for process control by a DCS, PLC or some other control system and are easily configurable or diagnosed with a HART handheld communicator (HHC). Several digital control system vendors offer a HART based systems for predictive maintenance that take advantage of the HART devices’ self-diagnostic capability. The disadvantage to HART is that the digital signal is slow. A maximum of 16 HART devices can be connected on a HART multi-drop loop. In that case, the analog signal is fixed to a value of 4mA.

The advantages of MODBUS RTU are that it is strictly digital (RS485) and it’s relatively fast but it does require at least two wires for signal and two wires for power; unlike HART that has signal and power over the same two wires. A significant number of MODBUS RTU addresses can be connected in multi-drop on the signal RS485 data link.

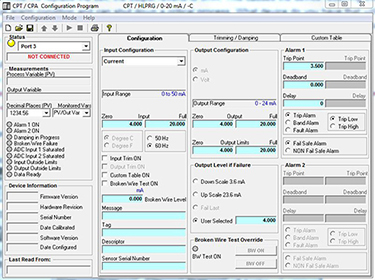

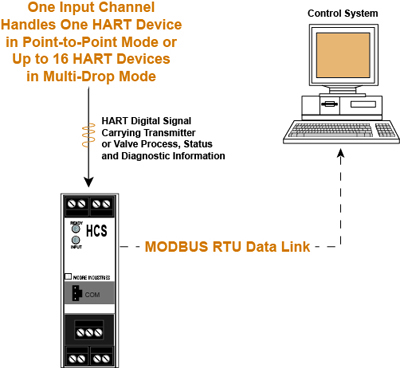

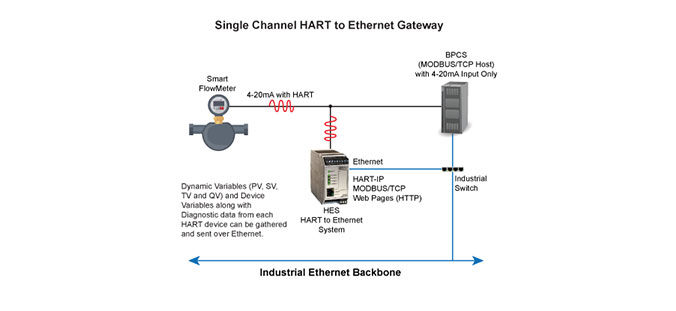

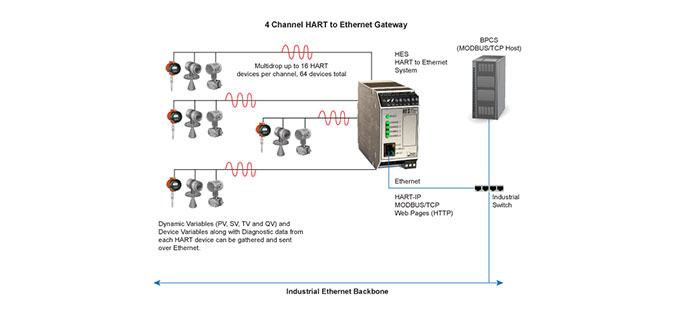

The HART Concentrator System HART-to-MODBUS RTU Converter (4-Wire) HCS is a HART Master (either the primary of the secondary master), and sends queries to the HART device(s). The HCS can communicate with up to 16 devices in multi-drop mode on one twisted pair loop. The collected data is stored in MODBUS RTU registers in the HCS. On the MODBUS side, the HCS is a MODBUS RTU Slave, so it responds to queries from a MODBUS RTU Master. The MODBUS RTU Master can only read data from the HCS. It cannot write data to the HCS with the intent to change settings in the HART device(s).

In a HART multi-drop loop, each instrument will have its own unique HART address. HART does not allow simultaneous communication to multiple instruments in a multi-drop loop. Instead a HART master or host has to poll each HART slave’s unique address and communicates with one HART device at a time. Moore Industries’ HCS HART Concentrator System converts a HART digital signal to a serial (RS-485 or RS-232) MODBUS RTU communication protocol. This allows HART transmitters and valves to interface directly with MODBUS-based monitoring and control systems. In point-to-point HART mode, the HCS concentrator system is set to monitor a single instrument. Wiring details for both single loop and multi-drop are shown in the HCS. In a multi-drop, the HCS sends queries and receives data from each HART instrument in turn. This follows the defined HART protocol.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

One of our customers uses ethylene for its process feed and has installed a new ethylene terminal with a 18m3 storage tank. It was necessary to install a new pipeline network to connect the terminal to production plants, other existing pipelines, and to neighboring companies using ethylene. For safety reasons, the pipeline was buried 1.5 meters deep.

One of our customers uses ethylene for its process feed and has installed a new ethylene terminal with a 18m3 storage tank. It was necessary to install a new pipeline network to connect the terminal to production plants, other existing pipelines, and to neighboring companies using ethylene. For safety reasons, the pipeline was buried 1.5 meters deep.

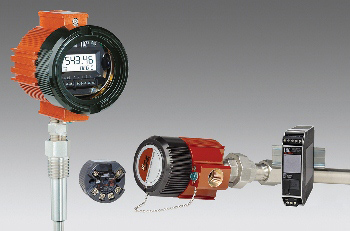

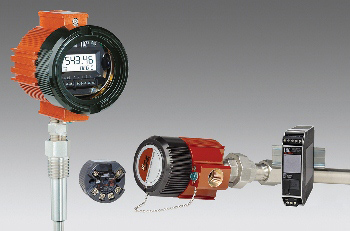

To monitor temperatures across the pipeline, 16 temperature sensors needed to be installed at various points. Because the integrity of the pipeline was critical for safety reasons, there could be no welding or other intrusions into the pipe. This led to using skin sensors that meet ATEX Explosion-Proof requirements to take the temperature measurements.

A typical solution is a 6mm-diameter mineral-insulated RTD or T/C sensor with a skin path that is strapped to the underground pipe while a cable travels to the surface where the head is installed. The problem with this design is if the sensor fails, it requires expensive digging near the underground pipeline to replace. A better solution uses a pipe skin mounting block strapped onto the buried pipe, a 1/2"-diameter stainless steel pipe that reaches the surface and a transmitter directly mounted onto the pipe. This allows a sensor to be replaced without costly digging but also means that a sensor needs a sensitive tip.

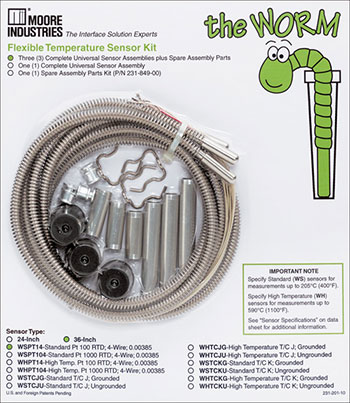

A perfect choice for this application is the WORM Flexible Sensors for Thermowell Temperature Assemblies. It provides accurate, fast readings and its flexible design with a universal length allows it to reach almost any spot. The WORM’s unique flexible design allows installation quickly and it delivers step response times 13% faster than standard sensors. The installation kit provides parts for three different installation options. The WORM can be purchased in economical 10 packs. Check out the WORM data sheet for more details.

Want to learn more? Get the product data sheets on other products such as THZ3 & TDZ3 Dual Input Smart HART Temperature Transmitter, THZ DH & WL Smart HART and WirelessHART Temperature Transmitter (2-Wire), and BULLET WirelessHART Adapter.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. I have an application that requires an analog splitter. The single input signal to the splitter comes from a transducer, and the transducer requires loop power. The two outputs are going to an analog monitoring card on a PLC, which provides power to the connected 4-20mA signal signals. Is the ECT what I need?

Q. I have an application that requires an analog splitter. The single input signal to the splitter comes from a transducer, and the transducer requires loop power. The two outputs are going to an analog monitoring card on a PLC, which provides power to the connected 4-20mA signal signals. Is the ECT what I need?

A. If you need a device with two outputs and with output loop power, the MIX would be a good choice. However, this model does not provide loop voltage to the input. It is a dual channel isolator so you would connect the input signal in series to the two input channels. MIX 2 and 4-channel models draw operating power from the loop output side, where power is typically made available by the receiving device, such as a DCS or PLC.

The ECT “Splitter” on the other hand provides loop voltage to the transducer, and it also provides the voltage to the two output loops. It requires a power source separate from the output signals.

You can specify either 24DC or 117AC for the separate power input. If the outputs must be compatible with a control system input card that is providing loop voltage then the EP option for the ECT modifies them to be passive. However, a separate power source is still required. The ECT offers Superior signal isolation (up to 1500Vrms). An ECT with the following model number would meet your application requirements: ECT/4-20MA/4-20MA/24VDC/-EP [DIN]

Quality and industrial strength protection stops ground loops, motor noise, and other electrical interference from affecting process signals. The ECT offers RFI/EMI protection against the unpredictable, harmful effects of radio frequency and electromagnetic interference. There is even a –RF option for enhanced protection in especially noisy environments.

Please visit our Interface Solution Download Center for more information on the MIX or the ECT line of products.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. I want to split out the HART variables from a smart multi-variable transmitter's 4-20mA analog output. My preference is to have the secondary variable (SV) and tertiary variable (TV) represented as additional 4-20mA outputs so I can connect those to spare analog input channels in my DCS. Can the HIM do that?

Q. I want to split out the HART variables from a smart multi-variable transmitter's 4-20mA analog output. My preference is to have the secondary variable (SV) and tertiary variable (TV) represented as additional 4-20mA outputs so I can connect those to spare analog input channels in my DCS. Can the HIM do that?

A. Yes, it can. The HIM is a Smart HART® Loop Interface and Monitor can be configured to act as a Primary or Secondary Master and can read up to 4 of the dynamic variables of a HART transmitter and can assign them to up to three analog 4-20mA outputs with no additional process penetrations or wiring. A free simple-to-use PC program lets you program the HIM in minutes so that it interfaces with every HART-compatible monitoring and control device including:

- Multivariable Mass Flow Transmitters

- Coriolis, Magnetic, Ultrasonic and Vortex Flow Meters

- Dual-Sensor Temperature Transmitters

- pH Transmitters

- Pressure Transmitters

- Radar and Hydrostatic Level Transmitters

- Valve Positioners and Damper Operators

When configured as a Primary or Secondary Master, the HIM operates in the Normal(Poll/Response) Mode. Additionally the HIM can be configured to communicate in Burst Mode or Listen Mode; which are both passive modes where the HIM does not need to control poll the HART slave transmitters.

Installed transparently across the 4-20mA instrument loop, the HIM reads the HART digital data that is continuously being transmitted on a smart transmitter’s analog loop wires, and converts it to 4-20mA signals that can be readily accepted by a DCS or PLC. This allows you to continuously track a multivariable transmitter’s second, third, and fourth variables.

In the future if you want to just isolate or split off a HART/4-20mA signal, then Moore Industries offers isolators, which can pass the digital HART component variable of the signal. Isolator models Moore Industries manufactures are the HIX, HIT, SSX, and SST.

Find out more about the HIM Smart Hart® Loop Interface and Monitor.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. Can the ECT-DIN, configured for 4-20mA input and 4-20mA output, be calibrated to give 4-12mA output when the input is 4-20mA so that the output is 1/2 the input? We have a radio I/O signal that is scaled to 4-20mA for 0-65,535 raw units. When sent to the PLC over MODBUS, it can't be read properly since the maximum register value size for the PLC is limited to 32,767.

A. The ECT with 4-20mA input/output doesn’t have enough adjustability to do a split range like the one you describe. Although it is possible for us to supply a special version of the ECT with 4-12mA or 12-20mA output, or you can use a PC configurable unit such as the CPT/HLPRG/0-20MA/117AC [DIN].

The universal CPT PC-Programmable Temperature Transmitter and Signal Isolator/Converter accepts a direct signal input from a wide array of sensors and analog devices including 23 RTD types, 9 thermocouple types, current and voltage signals, resistance and potentiometer devices, as well as direct millivolt sources. The 4-wire (line/mains-powered) CPT provides an isolated and linear current or voltage output (any range within 0-20mA or 0-10V) proportional to the input. The signal is ready for direct interface with readout instruments, recorders, PLC, DCS, or PC-based SCADA systems.

The CPT data sheet, manual, and configuration software can be downloaded from our site.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. We want to use a SPD Field-Mount Programmable Loop Display with a radar transmitter mounted on the top of a cone-shaped bottom tank that outputs 4-20mA signal, and we would like to know how to account for the linearization function representing the volume measurement in the tank at various levels?

Q. We want to use a SPD Field-Mount Programmable Loop Display with a radar transmitter mounted on the top of a cone-shaped bottom tank that outputs 4-20mA signal, and we would like to know how to account for the linearization function representing the volume measurement in the tank at various levels?

A. There are several things you can do depending on what information you have regarding your tank. Some tanks come with a strapping chart and the chart will tell you what volume you have at different levels inside the tank.

In this case, you can load a list of ordered pairs in a CSV (comma separated value) format into the SPD. Alternatively the SPD configuration software allows you to import a CSV (comma separated value) file that represents your linearization table, from Microsoft Excel for example. The SPD allows for custom curves using up to 128 linearization points.

If you do not have a strapping chart, you will need to do some math to relate the level in the tank to the tank volume based on the geometric shape(s). For example, at 5 inches you may have 5 gallons, and at 8.5 inches, you might have 10 gallons. If you have a vertical cylinder on top of a cone, the calculations should be relatively easy. A more difficult calculation would be a horizontal cylinder with F&D (flanged & dished) heads and with various nozzles.

The SPD is an excellent choice as a programmable field-mount loop indicator with extra-large 5-digit display that has large 29mm (1.15 in) digits for long-distance viewing and can be ordered with a back-lit option. The optional back-lit display makes it easy to read in dark conditions. Superior accuracy allows the SPD to display process information ±0.012% of input scale, it can operate in ambient conditions as low as -40°F, and a standard SPD is loop-powered by less than 2.3 volts (2.3VLP power input module). The SPD is also programmable with supplied configuration software to display a percent or any other engineering unit (EGU) of up to 5 characters.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. What is the maximum impedance that the output of an output loop powered ECT-DIN can drive?

Q. What is the maximum impedance that the output of an output loop powered ECT-DIN can drive?

A. For the output powered ECT (model ECT/4-20MA/4-20MA/12-42DC [DIN]) the max impedance that the output can drive depends on the loop voltage that you supply in series. For example, if you use a 24Vdc supply in series with the ECT’s output, the ECT uses 12V of the 24, and 12V is left over to handle loop loads: 12V/.02A=600 ohms. Note that you may want to account for the transmitter tied to the input of the ECT going to a fail high level of 23mA. If so, then the max impedance level will only be 521 ohms.

The ECT-DIN is a signal isolator, converter, repeater, booster and splitter and is available in 2-wire and 4-wire powered models with the ability to match the ECT to the type of AC or DC power available at each location, superior signal isolation up to 1500Vrms, and RFI/EMI protection.

The ECT-DIN also allows you to send the output from one transmitter to a second location. Additionally you can protect expensive monitoring/control equipment by eliminating common electrical paths or create a buffer between devices to allow interruption of one leg of a loop without impacting the other (see gallery image below for example). The ECT-DIN can even step down unsafe high level signals with an optional external input transformer (-EM option), allowing you to step down high level AC current inputs.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. I want to share a critical pressure signal with my DCS that is now part of our safety instrumented system (SIS) and have a two part question. First, do your isolators pass the HART diagnostic data that comes from my SIS smart pressure transmitter? Second, if there is a total failure of the pressure transmitter, where will the output of the isolator go to that is feeding my DCS?

Q. I want to share a critical pressure signal with my DCS that is now part of our safety instrumented system (SIS) and have a two part question. First, do your isolators pass the HART diagnostic data that comes from my SIS smart pressure transmitter? Second, if there is a total failure of the pressure transmitter, where will the output of the isolator go to that is feeding my DCS?

A. Yes, we have isolators that were designed specifically for these types of applications. The SSX and SST are exida approved SIL 3 capable isolators that pass HART data between any HART host or handheld device and the field transmitter. The second part of your question has two answers.

The SSX is an output loop powered isolator and as such when the input goes to 0mA the output will only drop to a minimum of about 2-2.5mA. The floor or minimum output is necessary because the SSX will need some level of current to keep its electronics circuit powered.

The SST is a four wire isolator so it behaves a bit differently. The SST’s output will follow the input through the entire range. For instance, if the input goes to 0mA or open circuit the output of the SST will follow the input all the way down to 0mA. Depending on your DCS settings, you can then choose when and how you want to alarm on the pressure transmitter’s health or loop status.

Download the data sheet to learn more about the SSX and SST.

Q. Do you have a temperature control solution for a batch process chamber we have? We have a manufacturing process that uses a critical batch process chamber requiring an RTD that senses the temperature. When the process chamber is being used, we need to maintain temperature, so we have a secondary temperature monitor to help in case of a fail-over. To do this, I need to connect to our RTD that has dual 4-wire inputs and be able to switch from the primary to secondary if the primary is disconnected or fails.

Q. Do you have a temperature control solution for a batch process chamber we have? We have a manufacturing process that uses a critical batch process chamber requiring an RTD that senses the temperature. When the process chamber is being used, we need to maintain temperature, so we have a secondary temperature monitor to help in case of a fail-over. To do this, I need to connect to our RTD that has dual 4-wire inputs and be able to switch from the primary to secondary if the primary is disconnected or fails.

A. You can use a Moore Industries’ THZ3-DIN temperature transmitter to precisely control the temperature. The THZ3-DIN can accept two 3-wire RTDs and can be configured so that its 4-20mA analog output is configured for failover/backup. If the primary RTD fails or is disconnected, the THZ3 automatically switches to the secondary RTD, it gives you a HART®alarm (and display an error if TDZ3 is used), and allows you to maintain the temperature measurement in the chamber.

You can use your existing 4-wire RTDs as 3-wire elements by taping off one of the leads. You will still have lead length compensation with the 3-wire RTDs as long as the leads are the similar length and have equal resistance.

The THZ3 can be configured by using a HART® hand held configurator or with PACTware running on a PC. A CDROM is provided with the PACTware installation files and DTM for the THZ3 with the shipment of the device. The THZ3 data sheet, manual, HART®DD, PACTware installation files, and the DTM are also available for download on Moore Industries site.

An easy-to-use yet robust Dual Input Smart HART® Temperature Transmitter, the THZ3 configures quickly and easily to accept a direct signal input from a wide array of sensors and analog devices including 14 RTD types and direct millivolt sources. The THZ3 has dual sensor input for Backup and Failover Protection, Average and Differential measurement and Low or High Select. It also has advanced RFI/EMI protection and ambient temperature compensation that helps guard against environmental factors that can quickly degrade measurement accuracy. Built-in 20 bit input resolution delivers exceptional digital accuracy of ±0.1°C (±0.18°F) with all Pt RTDs and is HART® 7 compliant with exception based reporting and dynamic variable mapping. There's even a High Availability Option that enables the user to select how the AO behaves when there is an input failure or out-of-range value detected by the transmitter that prevents nuisance alarms on startups.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. Can the PSD PC-programmable loop display pass HART® data without problems through the device if placed in a loop with a HART® capable transmitter?

Q. Can the PSD PC-programmable loop display pass HART® data without problems through the device if placed in a loop with a HART® capable transmitter?

A. The input of the PSD connects in series to the existing 4-20mA/HART®loop as if it was just an added resistance and only reads the analog 4-20MA signal. The PSD does not interfere with the HART®digital signal being transmitted on the loop.

Since the PSD does not have a path to ground or an output that could connect to another device, ground loops or other issues like extraneous conducted noise are not a problem.

However, when these loops do connect to devices that have separate ground paths or outputs problems can certainly arise. For these situations we recommend HART® pass-through isolators such as the HIX 2-wire output-loop powered unit or the HIT, a 4-wire mains powered isolator.

Moore Industries’ HART Isolators are a highly economical solution to common and costly problems that plague many of today’s “smart” process loops offering protection from surges, spikes, and transients up to 1500Vrms. You can safely share the HART® output of one transmitter with a secondary control or recording device allowing for redundancy without further burden or risk on a process loop. As an added bonus, you can perform equipment maintenance without loop downtime by isolating legs of the loop, making it possible to remove those instruments from the circuit without affecting other equipment. Protect and enhance your HART® investment with the 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT.

Learn more about the HIT/HIX HART Isolator and the PSD PC-programmable Loop Display.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: A Type K thermocouple is being used in a high temperature furnace environment for temperature measurement. However the Type K thermocouple is drifting too much. Is there something I could do so I don't have to change it out frequently or is there another type of thermocouple I could use?

Q: A Type K thermocouple is being used in a high temperature furnace environment for temperature measurement. However the Type K thermocouple is drifting too much. Is there something I could do so I don't have to change it out frequently or is there another type of thermocouple I could use?

A: You could use a Type N with Inconel 600 Material, which is designed to perform well at high temperatures (over 2000F) and helps prevent corrosion in environments where atmospheres are reducing or alternately oxidizing and reducing. This would be particularly helpful for a furnace process that includes heating and cooling with moisture present, creating potential for oxidation to form from the process. Other high temperature environments that benefit from Type N with Inconel 600 Material include boilers and cookers processes or extreme environments where the thermocouple cannot be replaced easily.

In terms of their basic function, Type K and Type N thermocouples are similar. Type K is one of the most common type of general purpose thermocouple. However, the environmental setting that your thermocouple will be used in can affect your choice. Type N thermocouples provide a higher level of stability and durability in adverse environments than Type K thermocouples.

To be more specific, Type K thermocouples are susceptible to a phenomenon called Green Rot, or oxidation around the thermocouple. Green Rot is oxidation inside the thermocouple sheathing caused by operation at certain low oxygen environments, creating large negative calibration drifts leading to curve changes over time. Potential IR failure can happen, where the internal elements short and touch the outer sheathing due to oxidation (Green Rot).

Type N is also a viable choice when adverse environmental factors and high temperature requirements are an issue and there is difficulty in frequently changing out the thermocouple. While a Type N with Inconel 600 Material is only 20% higher in cost than Type K, the Type N can perform longer without the drift that oxidation causes, preventing the need to shut down the process to change out the oxidized thermocouple.

If you decide that Type N thermocouple isn't for you and are using a Type K thermocouple where your environment is the key factor instead of temperature, you can reduce the chances of Green Rot by increasing the oxygen supply through the use of larger diameter protecting tubes. The opposite approach can also work by inserting a mechanism to absorb oxygen inside a tube which can bring oxygen levels below what will promote oxidation.

Moore Industries can help when you are deciding if Type N is viable replacement for your Type K thermocouple application. You can contact us with your questions or if you need to know more about a product, price or availability.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. I have two different control systems and I need some splitters to split a 4-20 mA signal. I may need to have the loop isolated. Can you help specify a splitter that can send the signal to both control systems where I can use the splitter connected in a series on the original loop? My company has used the SIX in the past, would this work?

Q. I have two different control systems and I need some splitters to split a 4-20 mA signal. I may need to have the loop isolated. Can you help specify a splitter that can send the signal to both control systems where I can use the splitter connected in a series on the original loop? My company has used the SIX in the past, would this work?

A. The SIX can be used in a “splitter” application when its input is connected in series on the original loop. The output of the SIX 2-Wire Signal Isolator/Converter gives you the isolated loop. The versatile SIX can be used as a signal isolator, converter, and repeater. It is an excellent choice for installation in the plant or control room. The 2-wire (loop-powered) SIX derives its power from the output loop, eliminating the need to install an additional power supply.

If you decide you need to have the two control systems isolated from the original signal, then you can use the ECT-DIN model ECT/4-20MA/2X4-20MA/117AC* [DIN] Signal Isolator, Converter, Repeater, Booster and Splitter for more versatility. The ECT-DIN features a solid metal housing that stands up to the continuous, daily rigors of process control and factory automation applications.

Like the SIX, the ECT's input is wired in series with your original loop. The ECT then gives two separate and isolated outputs for your two control systems. Each output is capable of driving 600 ohms of output load. This version of the ECT also offers a TX option that powers a two-wire transmitter connected to its input.

If you have functional safety in mind, the SSX/SST Model number SST/4-20MA/2X4-20MA/117AC* [DIN] works like the ECT but is part of Moore Industries’ FS Functional Safety Series. The SSX/SST Safety Series Isolator and Splitters are exida® approved, SIL 3 capable. The SSX is 2-wire (loop powered), and the SST is 4-wire (line/mains powered). The SSX/SST provides isolation and signal conversion for your SIS (Safety Instrumented System) needs. These units protect and enhance loops and also pass valuable HART® data from the field transmitter to host systems and vice-versa.

The ECT and SST are line powered and supply the voltage to their outputs, so the control systems receiving their outputs must have passive inputs. If your control system inputs are active (providing power), contact us and we can modify the ECT or SST for those loops too.

Other things to consider:

Do you need to pass digital HART signals between the input and outputs?

- The ECT filters the HART component

- The SST passes HART on the outputs (both or neither)

- The SST is from our line of Functional Safety products

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: Is there a less complicated and economical solution to replace a failed thermocouple than a complete shutdown of a boiler?

A: To address this issue, we need to note that furnaces, boilers, and reactors present an interesting problem when trying to replace a failed thermocouple. Typically to replace thermocouple sensors, the entire furnace or boiler must be shut down for long periods of time creating downtime and lower productivity. Most facilities will try to schedule this type of shut down once every 4 to 5 years because shutdowns are time consuming and costly. Once the boiler is down, most customers will remove all of the sensors, and perform a full replacement, to prevent shutdowns for as long as possible. Facility maintenance personnel with special training in “Small Space Confinement” must do the replacements.

Because this kind of replacement is costly in both downtime and new sensors, if a sensor fails, that particular temperature measurement is lost until the next maintenance schedule. A facility will not shutdown a boiler earlier than originally scheduled even if more than 50% of the sensors fail before the maintenance schedule, unless there is a critical safety issue requiring shutdown.

Thermocouples are long, typically about 20 to 40 feet long. They have a small metal pad welded to the tip of the sensors sheath with the weld pads tack welded to the surface of the Protection Tube (pipe) inside the high-temperature area making them typically expensive to replace.

Moore Industries has a simple and economical solution to this complicated process: The WORM Flexible Temperature Sensor. It lets you replace the sensor without removing the Protection Tube or disassembling the thermowell by just replacing the broken sensor. The High Temperature WORM is a flexible sensor for thermowell temperature assemblies that is available in standard sensor types including 100 and 1000 ohm platinum, nickel and copper RTDs, and J-, K-, T-, E- type thermocouples with step response times 13% faster than standard sensors. The WORM comes in a universal length so there’s no need to stock an expensive array of different sensor lengths. With a quick measurement and a simple trim-to-length, the WORM handles nearly every thermowell assembly.

For boiler tube applications, the WORM ships with a hollow protection tube that includes a weld pad with a thermocouple WORM Sensor that enables sensor replacement from outside of a boiler. The tube is hollow and allows a flexible Worm Sensor to slide down inside the Protection Tube from outside the boiler. This allows the customer to replace a sensor, if it should fail, anytime while the furnace is still up and running.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. Is there a signal conditioner with 0-2Vdc input and two isolated 4-20mA outputs with 24Vdc? I need it as compact as possible because I need to install it horizontally in a cabinet.

Q. Is there a signal conditioner with 0-2Vdc input and two isolated 4-20mA outputs with 24Vdc? I need it as compact as possible because I need to install it horizontally in a cabinet.

A. The ECT-DIN series dual 4-20mA output can be provided with a modified input to accept a 0-2Vdc signal. Moore Industries offers a build option from the factory (the ECT which acts as a Splitter). The model number for an ECT with this configuration is ECT/0-2V/2X4-20MA/24DC [DIN]. Typical installation of an ECT is a DIN mount so the housing we offer is a DIN-style housing which mounts on 32mm G-type (EN50035) and 35mm Top Hat (EN50022) rails.

The ECT-DIN is rugged as well as reliable and is available in 2-wire (loop) or 4-wire (line/mains) powered models.

The complete family delivers economical solutions for an expansive range of signal interface applications such as protecting equipment and signals by eliminating common electrical paths, amplify signals allowing more instruments on an overburdened loop, isolate signals to prevent erratic measurements, convert signals so field devices can interface with equipment such as an indicator or PC-based SCADA system, split one signal to allow one primary measurement to be sent to two separate systems, and solve bucking power supplies. The ECT has superior signal isolation up to 1500Vrms and stops ground loops, motor noise, and other electrical interference from affecting process signals.

For more information on the ECT, view the product page.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. Can the SPA2 be placed in an existing 4-20mA loop as passive?

Q. Can the SPA2 be placed in an existing 4-20mA loop as passive?

A. The SPA2 can be wired using the passive input (+I and COM) in series in your 4-20mA loop. It will add about 20 ohms to the loop.

When ordered with the Analog Output (-AO) option, the SPA2 provides a proportional and isolated analog retransmission of the input signal that can be sent to remote monitoring/control devices like a DCS, PLC, PC, indicator or data recorder, making it completely isolated from the input. All analog parameters can be selected using the SPA2 push buttons or the free easy-to-use Intelligent PC Configuration Software.

The SPA2 Programmable Limit Alarm Trips provide on/off control, warn of unwanted process conditions, alarm on rate-of-change, and provide emergency shutdown. Very versatile, the SPA2 accepts a signal input from transmitters, temperature sensors, and a wide array of other monitoring and control instruments such as current and voltage signals, 23 RTD Types, 9 Thermocouple Types, resistance and potentiometer devices, and Direct Millivolt Sources. Features of the SPA2 include 20-bit input resolution, long-term stability with up to 5 years between calibrations, large 5-digit process and status readout, and isolated RFI/EMI protection.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. Currently, I have an application where I need to configure my SIY input to 0-1mA. Is this possible?

Q. Currently, I have an application where I need to configure my SIY input to 0-1mA. Is this possible?

A. Yes, the minimum input span possible on the SIY is 1 mA, allowing you to configure it to 0-1 mA.

Not only can you configure the SIY to 0-1 mA, the enhanced configuration software allows you to trim input sensor readings, customize input linearization curves, program output damping, and calibrate other loop instruments. The SIY handles the majority of current/voltage interface applications you are likely to encounter.

Moore Industries’ SIY PC-Programmable Signal Isolator/Converter combines smart digital technology with advanced analog operation to deliver superior reliability, accuracy, and ease of use. To learn more about the SIY visit our website.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. When the 535 1/4 DIN Single Loop PID Process Controller loses power with remote setpoint on, it comes back up in local setpoint mode. Is there a way to have the 535 always come back up in remote setpoint mode when power is restored?

Q. When the 535 1/4 DIN Single Loop PID Process Controller loses power with remote setpoint on, it comes back up in local setpoint mode. Is there a way to have the 535 always come back up in remote setpoint mode when power is restored?

A. Yes, the 535 can come back up with remote setpoint. To make the 535 power up using remote setpoint:

In the configurations menu

- Go to the SPECIALmenu

- Go to PWR. UP: SP

- Select REMOTE

Details are on page 51 (number on the bottom right or page 58 of the PDF) in the user manual. For your convenience, the image is attached at the bottom of this page.

Check out more on the 535 1/4 DIN Single Loop PID Process Controller.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. As part of a power distribution process I need a dual signal isolator/converter/splitter that has an input of 0-1mA, outputs of 0-1mA and 4-20mA with 117VAC power input? It needs a DIN housing so it can be mounted in an existing cabinet.

Q. As part of a power distribution process I need a dual signal isolator/converter/splitter that has an input of 0-1mA, outputs of 0-1mA and 4-20mA with 117VAC power input? It needs a DIN housing so it can be mounted in an existing cabinet.

A. Moore Industries has the ECT Signal Isolator, Converter, Repeater, Booster and Splitter and comes in 2-wire (Input-Loop Powered) and 4-wire (Line/ Mains Powered) versions with input 0-1mA, with outputs 0-1mA and 4-20mA, with 117VAC power input in an aluminum DIN rail mounted housing.

- When ordering, specify the model number in this format: Unit / Input / Output / Power / Options [Housing]

- To order the model discussed use this model number: ECT/0-1MA/0-1MA,4-20MA/117AC [DIN]

Moore Industries also offers optional NIST Traceable Test Reports with recorded test data.

To read more on the ECT or on other products please go to our website

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. On a 4-20mA gas detector, while we replace the cell, the output reverts to 3mA. This causes the device receiving the 4-20mA signal to go into a critical alarm condition and can shut down a critical process. What device do you have that will keep the output at no less then 4mA? It would also be convenient to have this instrument provide me with a relay alarm contact output when my input goes to 3mA. It can be 24Vdc or 120Vac. It should be in a DIN housing.

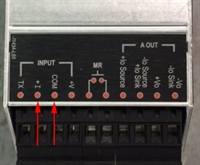

A. Moore Industries CPT PC-Programmable Temperature Transmitter and Signal Isolator/Converter CPT/HLPRG/0-20MA/117AC/-C [DIN] can be used for this application.The selected model allows you to limit the minimum and maximum output, even when you are replacing the cell. The alarm relay option allows you to set an alarm at whatever level below 4mA for maintenance notification. Figure 1 below shows a configuration that would work for your application. A configuration cable is required to utilize the PC programming capability.

The CPT has a menu selection for upper and lower limits. You can set the low alarm limit there, such as 3.5mA.

Figure 1. CPT PC Configuration

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I want to use a SIX Signal Isolator/Converter in a loop with a cable run of 1200’. Are there cable parameter values (i.e. maximum inductance/capacitance) that must be met in order to maintain the FM Non-Incendive certification?

A: The certification by FM of the SIX for Non-Incendive Class 1 Div 2 does not include any cabling restrictions. The maximum cable length is a function of the available compliance voltage and the total resistance (loss in the wire and device loads).

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: The SRM Safety Relay Module only has three contacts. Is it possible to add extra contacts? Also, is there specific wiring required to obtain a SIL 2 rating?

Q: The SRM Safety Relay Module only has three contacts. Is it possible to add extra contacts? Also, is there specific wiring required to obtain a SIL 2 rating?

A: You can connect a wetted contact to the power terminals of two SRMs in order to have more than three contact outputs. Connect jumper wires to the input terminals of these SRMs. The wetting current must be sufficient to drive the coils of the two SRMs.

The SRM installation manual has detailed directions for installation in Safety Instrumented Systems (SIS) as well as information about connecting the coil (input) side to either dry or wetted contacts. In addition, Figure 5.3 in the manual shows how to connect a wetted contact to a single SRM.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We are interested in your HCS HART Concentrator System. What are the options for converting a single HART transmitter or for converting 16 transmitters with one unit?

A: You don’t have to choose between connecting one or multiple transmitters to the HCS. A single HCS unit can be configured by the user to interface with a single drop HART loop (one HART device) or to a multi-drop HART loop (2 to 16 HART devices).

In point-to-point HART mode, the HCS is set to monitor a single instrument. All process and diagnostic data carried on the HART data string is converted to MODBUS RTU.

In a digital multidrop HART network, up to 16 HART instruments digitally communicate on the same wires. The HCS can be set to monitor any or all instruments and/or valves within the network. Only one MODBUS address, and one communication link (such as twisted wire pair), is needed to send the process and diagnostic data from up to 16 HART devices to a MODBUS host.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have been using the ECT-DIN in our applications where we need to split one 4-20mA input to two outputs. The model number for our current units is ECT/4-20MA/2X4-20MA/117AC/DIN. We now need to split a signal to three outputs. Do you have a product that will help us to do this?

A: If you need the splitter to provide the loop voltage for the third 4-20mA output, as you did in the previous installation, you can use two of the ECT/4-20MA/2X4-20MA/117AC/-TX [DIN] models and wire your 4-20mA in series to each of the ECT's inputs. This will provide you with up to four isolated outputs. This ECT model also comes standard with a -TX option which provides loop power, if required, to a power a two-wire transmitter.

An alternative option would be to use our MIX four channel isolator, model number MIX/4X4-20MA/4X4-20MA/12-42DC [DIN]. The input signal needs to be connected in series to at least three of the four inputs to meet your requirements. This option will also provide you with one spare channel.

It is important to note that your receiving device will need to provide the loop power for each channel since each of the four MIX channels are output loop powered (passive outputs).

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: Will the SIX Signal Isolator/Converter pass input signals through if the output is disconnected? We will be replacing our DCS, so we need to know if the input side will continue to work while the DCS is disconnected.

Q: Will the SIX Signal Isolator/Converter pass input signals through if the output is disconnected? We will be replacing our DCS, so we need to know if the input side will continue to work while the DCS is disconnected.

A: The SIX’s input has a passive 50 ohm resistance. Connecting the input of the SIX in series with the loop is the same as adding a 50 ohm resistor. This passive resistance is maintained whether the SIX’s output is receiving power or not.

Stay up-to-date on future developments and enhancements on this product and our other product lines, sign up for our customer newsletter.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

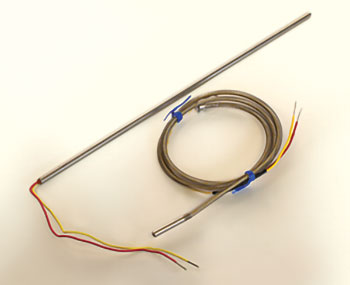

Q: Does the WORM Flexible Sensor RTD have a 3-wire option? If not, can I eliminate the fourth wire by jumping two of the parallel wires together?

Q: Does the WORM Flexible Sensor RTD have a 3-wire option? If not, can I eliminate the fourth wire by jumping two of the parallel wires together?

A: Yes to both questions. If your transmitter or other measurement can only deal with a three-wire RTD, you can stow the orphan lead or connect it to the other wire of the same color. The alternative is to purchase a special three-wire version of the WORM RTD. However, to achieve greater measurement accuracy we recommend using a 4-wire RTD. You can learn more about the benefits of 4-wire RTDs and other ways to improve accuracy in our A Practical Guide to Improving Temperature Measurement Accuracy white paper.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We currently are using TCA Thermocouple Alarm units in our plant (model TCA/K-10MV/SX1/117AC/[STD]). The user’s manual says that the deadband is fixed at 1% of the input range. However, we need the TCA to trip at a set point of 190°F and reset at 180°F. Is this model capable of meeting this requirement and do you still manufacture this model?

Q: We currently are using TCA Thermocouple Alarm units in our plant (model TCA/K-10MV/SX1/117AC/[STD]). The user’s manual says that the deadband is fixed at 1% of the input range. However, we need the TCA to trip at a set point of 190°F and reset at 180°F. Is this model capable of meeting this requirement and do you still manufacture this model?

A: Your model with the 1% deadband is not sufficient to handle the application. The model you need requires the Adjustable Deadband (-AD) option, which provides you a deadband adjustment of 1-20%. If you have a need for a larger deadband, the factory can assist you with selecting a newer microprocessor-based alarm module featuring increased configurability.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: In specifying the Moore STA / HLPRG / 3PRG / U / -AO [DIN] our end user has a concern about electrical protection for the analog output. The desire is to use 4-20mA Output Loop Voltage sourced by DCS for the AO; however, this voltage may fault at up to 132 VAC. Should our design add fuse protection in the external voltage circuit upstream of the STA to protect it from these surges? Or does the STA include features that protect it from these faults?

Q: In specifying the Moore STA / HLPRG / 3PRG / U / -AO [DIN] our end user has a concern about electrical protection for the analog output. The desire is to use 4-20mA Output Loop Voltage sourced by DCS for the AO; however, this voltage may fault at up to 132 VAC. Should our design add fuse protection in the external voltage circuit upstream of the STA to protect it from these surges? Or does the STA include features that protect it from these faults?

A: A fuse will limit current but not excessive voltage. If the DCS cannot be configured for a sinking input, then I recommend using a “sacrificial” isolator. Connect the sourced output of the STA into the input of an output loop powered isolator. The output of the isolator goes to the DCS’s sourcing input. If there is a 132V fault voltage from the DCS, it will risk damaging the isolator and not the STA.

An example of such an isolator that would work is an ECT/4-20MA/4-20MA/12-42DC [DIN].

If this analog output from the STA is part of a safety path, then consider using the SSX/4-20MA/4-20MA/12-42DC [DIN] as it is a Functional Safety isolator designed for safety instrumented systems.

Download the ECT-DIN data sheet for more information.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: Do you have a signal alarm unit for a tank level application? I need it to meet the following requirements:

Q: Do you have a signal alarm unit for a tank level application? I need it to meet the following requirements:

- Input signal accepts 4-20mA.

- Contacts opened or relay de-energized @ EL 208 ft.

- Equipped with up to four alarm trip relays.

- Individually configured for: set point, high or low trip, normally open or normally close, failsafe or non-failsafe, and latching or non-latching.

- Deadbands adjustable over 100% of span.

- Output relay equipped with form C contacts rated at 10A, 120VAC.

- All operating parameters adjustable from the front panel keypad.

- Operate on a 120V 60 Hz power source.

- Capable of supplying 24V dc power to two-wire transmitters.

A: This is a perfect match for the Moore Industries SPA2 alarm trip unit. The SPA2 can handle all of your above requirements, with an exception and a clarification. Alarm set points for 208 feet should not be a problem assuming you have ranged your 4-20mA input to equal some engineering unit range of at least 208 feet, i.e. 4-20mA = 0-500 feet. The exception is with the the form C relays on the SPA2. They are rated for 5A, not 10A. Therefore, if you need a 10A relay we recommend using an interposing relay in conjunction with the SPA2 outputs. An example model number is: SPA2/HLPRG/4PRG/U [DIN]

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: HIX Application - It appears that if the "Primary Master" loop (input loop side of the HIX) is broken or open circuited, the "Secondary" loop (output loop side of the HIX) will be 0mA. Is this true? Maybe I can put a zener across the primary process terminals to keep the current loop when the process opens? Also, are both or either loops bi-directional HART? I have a 4-20mA input signal that I'd like to share between two 4-20mA/HART process loops. Actually, we currently use another vendor's device to "split" one 4-20mA input to four process loops but it doesn't pass HART.

A: The HIX is an output loop powered device that is an analog circuit, so the output will follow the input as far down as possible. If the input goes to zero mA on the HIX input circuit, the output will go down to about 2mA, but not all the way down to zero. This is due to the active parts of the power supply circuit, on the output side of the HIX, that continue to consume some trickle power to keep the unit “alive”. Yes, the HIX supports bi-directional HART communication.

If you are looking for a single input, dual output device that passes HART, then take a look at the SST series. Utilizing two of these SST splitters will offer you the four process loops with HART pass through capability. This device also supports bi-directional HART communication.

The outputs of the dual output SST normally source the loop voltage, but there is an option to make both outputs “passive”.

Download the HIX/HIT data sheet or the SST data sheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I have a project for six RTD measurements that makes using standard fixed length sensors difficult because there is little clearance near the top of the thermowell for sensor insertion. It looks like your “WORM Sensor” would be an ideal fit for the application because of its flexible design. These RTD sensors need to be 100 or 1000 ohm platinum elements with Class A or 1/3 DIN accuracy ratings. They will be used to monitor chilled and hot water lines with min and max temperature limits of 30 F and 180 F. Maximum insertion length in these ¼ inch ID thermowells is about 10 inches. I noticed that your standard WORM length is 24 or 36 inches. Are custom length WORM sensors available? If so, what cost is associated with ordering multiple sensors at custom lengths? Lastly, we usually request test data with all of our sensors and check them in our air bath or heat block calibration units. Can you offer a test report or test data points with these WORM sensors?

Q: I have a project for six RTD measurements that makes using standard fixed length sensors difficult because there is little clearance near the top of the thermowell for sensor insertion. It looks like your “WORM Sensor” would be an ideal fit for the application because of its flexible design. These RTD sensors need to be 100 or 1000 ohm platinum elements with Class A or 1/3 DIN accuracy ratings. They will be used to monitor chilled and hot water lines with min and max temperature limits of 30 F and 180 F. Maximum insertion length in these ¼ inch ID thermowells is about 10 inches. I noticed that your standard WORM length is 24 or 36 inches. Are custom length WORM sensors available? If so, what cost is associated with ordering multiple sensors at custom lengths? Lastly, we usually request test data with all of our sensors and check them in our air bath or heat block calibration units. Can you offer a test report or test data points with these WORM sensors?

A: We stock the WORM Sensor in standard lengths of 24 and 36 inches for quickest delivery. At any time, you can order shorter lengths at any quantity at no additional cost. However, one of the many unique advantages of the WORM sensor is that it is field-trimmable. All that you need to do to shorten the insertion length of any WORM sensor is trim the length of the spring and lead wires. This makes it the perfect sensor for stores or stockroom. If you need a WORM sensor longer than 24 or 36 inches, contact us and we can build custom length WORMs to match your application requirements.

The 24 and 36 inch WORM sensors are sold separately or you can save money if you purchase our prepackaged WORMs in a three pack or 10 pack. The 10 pack of sensors, called the “Can of WORMS”, offers the greatest cost savings for your application of six elements. The WORM sensor was designed to handle two temperature ranges: Standard and High Temperature, designated respectively by “WS” and “WH” in the model number. The temperature limits in your application can easily be handled by the WS standard WORM element.

The 24 and 36 inch WORM sensors are sold separately or you can save money if you purchase our prepackaged WORMs in a three pack or 10 pack. The 10 pack of sensors, called the “Can of WORMS”, offers the greatest cost savings for your application of six elements. The WORM sensor was designed to handle two temperature ranges: Standard and High Temperature, designated respectively by “WS” and “WH” in the model number. The temperature limits in your application can easily be handled by the WS standard WORM element.

With regard to sensor accuracy, we only build our RTD sensors to meet the newest IEC 60751 standards. This standard addresses the requirements needed to meet tolerance levels required for different classes of RTDs that include Class AA, A, B and C. Moore Industries only supplies Class AA and A sensors when increased accuracy or calibration requests are mode on sensors and assemblies. Additionally we thermally age our sensors for 1,000 hours. When the RTD element is temperature aged, it ensures that the platinum substrate material inside the sealed element will provide a more stable and long term repeatable output. This helps reduce the frequency of transmitter and input card calibration due to sensor drifting.

Moore Industries offers certified calibration services for sensors and sensor-transmitter assemblies. For your application we can offer you a –VTD calibration option. With this option we will use our NIST traceable oil calibration bath to take and record five temperature/resistance points within your requested temperature range, and offer a test data report. This test report will list the sensor serial number, date of calibration and all of the NIST traceable calibration equipment we used to perform the test.

Most often our customers request that we calibrate and certify the full temperature assembly, using our –VTB option. This offers the best accuracy since we are matching your sensor to the transmitter and calibrating them as an overall measurement assembly or system. We only certify these assemblies utilizing Class A (.06%) or Class AA (.04%) sensors since they drift less and offer the most long term repeatable measurements.

For customers who are required to validate accuracy performance on a regular cycle, our -VTB calibration option reduces the need to calibrate so often. In many cases customers do not have the equipment with the required accuracy levels to perform onsite calibrations. Moreover, the cost of calibration performed by us is only a fraction of the cost that it would cost them.

Get the details on Moore Industries WORM Flexible Sensors. Download the Get Rid of Rigid technical paper for insights to using flexible sensors, and the WORM data sheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We want three 100 ohm, .00385 Alpha RTDs to measure heated glucose in railroad cars. We heat the glucose to 140-150°F, and want to use a 5-foot long flexible sensor with a head on top containing a terminal strip. We also want to run flexible conduit from the head with copper wire for easy replacement access. We can fabricate a bracket that would span the midway above the railcar that supports the housings and includes holes that allow the flexible RTDs to drop down for installation. What do you offer that is a fit for our application?

Q: We want three 100 ohm, .00385 Alpha RTDs to measure heated glucose in railroad cars. We heat the glucose to 140-150°F, and want to use a 5-foot long flexible sensor with a head on top containing a terminal strip. We also want to run flexible conduit from the head with copper wire for easy replacement access. We can fabricate a bracket that would span the midway above the railcar that supports the housings and includes holes that allow the flexible RTDs to drop down for installation. What do you offer that is a fit for our application?

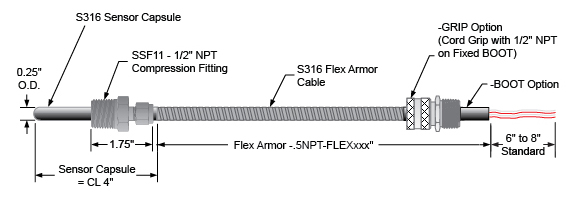

A: Moore Industries has several variations of its WORM sensor precisely for liquid measurement applications. Using the WORM with our specially-designed 12-inch weighted bar, which is potted at the end of its capsule, offers stability from swinging or moving when suspended in liquids. We also offer a -30G potted option which provides added protection from extreme shock in harsh environments.

One of the best features of this assembly is the Teflon insulated leads sealed inside a Teflon jacket. This protects the lead wires from liquids penetrating the insulation and potentially causing shorts. For maximum protection against very harsh abrasive environments, we have also added flex armor cable over the Teflon jacketed leads. Flex armor also acts as an additional weight to the entire assembly yet is still flexible enough to raise and lower the tip of the WORM.

Another feature of this assembly is the 0.50-inch outside diameter of the weighted bar. This allows insertion of the bar through a ½-inch NPT threaded hole for easy installation.

At the transmitter where the lead wires enter the housing, we use a sealed stainless steel sleeve attached to the flex armor cable which is sealed at the lead wires. This provides a sealed and rigid spot where we add a compression fitting for securing the assembly to the housing. In addition this sleeve and compression fitting allow the installer to adjust the depth of the WORM assembly.

For additional reading on Moore Industries’ WORM Flexible Temperature Transmitter, download these white papers: Measuring Molasses with the WORM and Get Rid of Rigid.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We want to install an

Q: We want to install an

STA / HLPRG / 3PRG / U / -AO [DIN] into our process and plan to use 4-20mA output loop voltage sourced by a DCS for the analog output, however this voltage may fault at up to 132 VAC. Should we design in fuse protection to the external voltage circuit upstream of the STA to protect it from these surges? Or does the STA include features that protect it from these faults?

A: A fuse will limit current but not excessive voltage. If the DCS cannot be configured for a sinking input, then we recommend using a “sacrificial” isolator.

To do this, connect the sourced output of the STA to the input of an output loop powered isolator. The output of the isolator goes to the sourcing input of the DCS. If there is a 132V fault voltage from the DCS, it will risk damaging the isolator and not the STA.

For information on the STA, download the data sheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. What is the least expensive way to speed up the response time of a sensor installed inside of a thermowell? We have a reactor associated with a quickly changing process and need to be able to control any sudden changes. What do you suggest?

Q. What is the least expensive way to speed up the response time of a sensor installed inside of a thermowell? We have a reactor associated with a quickly changing process and need to be able to control any sudden changes. What do you suggest?

A. We can suggest several solutions:

If you reduce the mass of the thermowell stem, which is the portion inserted into the process, sensitivity to the response will increase.

Another option is to add temperature sensitive paste to the inside of the thermowell to fill in the air space and allow temperature changes to more quickly conduct to the sensor sheath.