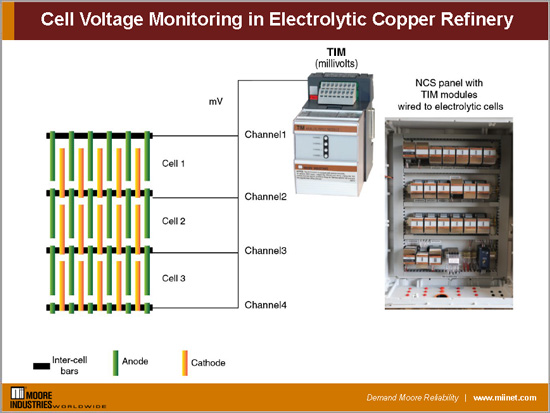

An electrolytic copper refinery needed an efficient and reliable way to monitor voltage on more than 700 electrolytic cells used to produce A grade copper. The refining process in this type of plant begins with copper anodes of 99% pure copper plates produced in a copper smelter. These copper anodes are submerged in an acidic copper sulphate solution, between stainless steel “mother” plates (cathodes) in the electrolytic refinery tank house.

A low voltage electric charge is fed through the tanks. Over a number of days, the copper anode dissolves into the copper sulphate solution. The positively charged copper content migrates electrolytically from the anodes to the stainless steel mother plates where they deposit and build up into a 99.99% pure copper cathode. The impurities are separated from the copper by falling to the bottom of the tank.

Pictured here is a column of 16 electrolytic cells and their rows of electrodes in a typical electrolytic copper refinery’s tank house.

At many refineries like this the cells number in the hundreds.

The copper is then stripped from the stainless steel mother plates and the copper is shipped as melting stock to mills or foundries where it is cast into wire rod, billets, cakes, or ingots, as pure copper or is alloyed with other metals. The impurities, or tank house slimes, leftover after the electrolytic refining contain a range of other valuable minerals including gold and silver which is further processed and recovered.

Moore Industries engineered Net Concentrator System (NCS) components to perform Cell Voltage Monitoring. The NCS components included 192 TIM Temperature Input Modules measuring cell voltage drop in millivolts, housed in 12 cabinets. The complete NCS system provides critical real-time performance monitoring of the cell voltages via Ethernet, improving overall house maintenance and management. This allowed the operations staff to realize significant gains in production and the quality and amount of copper production.

Key Attributes of the NCS:

- Modular electrically isolated I/O (500V channel-to-channel) with configurable ranging

- Operates in harsh environments -40 to 85C ambient operating temperature

- Quick and simple programming with Ethernet MODBUS/TCP and serial communication ports