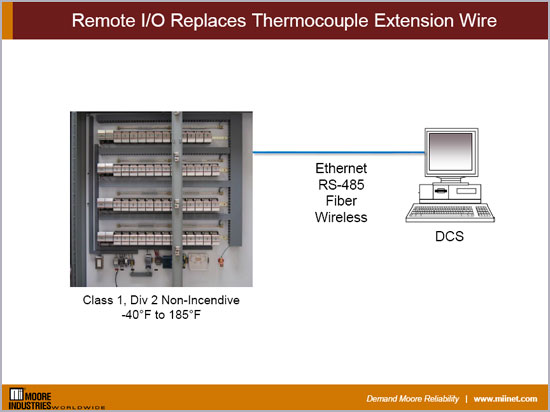

It is common practice to wire data acquisition thermocouples all the way to the DCS using thermocouple extension wire. Over time, extension wire corrodes and becomes contaminated causing unacceptable measurement errors. When that occurs, the two choices are to replace the same wire and perpetuate the problem, or change to a different technology.

Remote I/O is a valid cost balance between individual temperature transmitters and direct wiring thermocouples. It also eliminates thermocouple extension wire as an error source. Remote I/O has the same measuring circuit as a temperature transmitter, but the back-end communication is both MODBUS RTU and MODBUS /TCP.

When using MODBUS, if fiber optic communications or radios are desired, those options are available, and if all your data acquisition points came into the DCS as MODBUS, existing analog input cards can be eliminated or repurposed. Other advantages with MODBUS are that each input and output is isolated in all directions so there is never a ground loop, and each input and output has its own chip, so the loss of a processor would only cause the loss of one point.

The I/O hardware used in this application is the NET Concentrator System® (NCS) which is Class I, Div 2 certified and can tolerate ambient temperatures from -40 to +85°C. It provides a real-time signal gateway between the field and your control strategy, eliminating the constant degradation of thermocouple measurement accuracy caused by the thermocouple extension wire. Copper wire and an all digital measurement and delivery system assure the measurement is as accurate as the sensor.

Key Attributes for the NCS:

- Superior 20-bit input and 18-bit output resolution

- Installs in harsh ambient temperature conditions,-40°F to 185°F

- Class 1, Div 2 Non-Incendive Quick and simple programming

- Isolation and RFI/EMI protection

- Peer-to-Host and Peer-to-Peer operation

- Transmit any distance, over any terrain

- Data logging capabilities

Check out more on the NET Concentrator System® (NCS) or on Moore Industries’ custom Instrument Panels and Systems from our catalog that are turnkey solutions for your process, automation, Safety Instrumented System (SIS) monitoring, and control needs.

Download the Instrument Panels and Systems line card PDF to learn more about high-density panels, field-mounted cabinets, control room cabinets, pneumatic Instrument Interfaces panels, components and more.