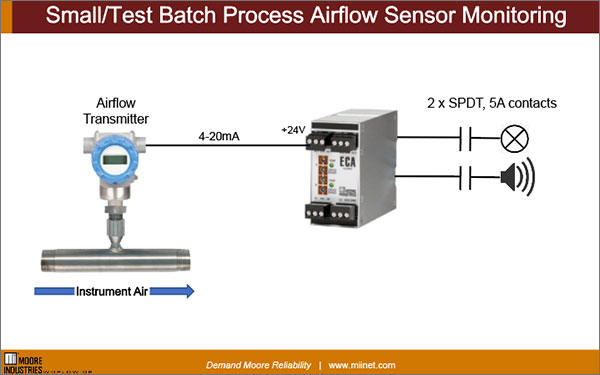

Many industrial facilities have R&D divisions or labs onsite to assist with small batch runs or testing to ensure that large scale production has met or will meet quality control standards. Often these labs are filled with smaller pneumatic valves that use air from onsite industrial compressors. If air header flow rates being supplied by these compressors are not sufficient, expensive test batches can be ruined or critical lab results can fail.

To verify that proper flow rates are supplied to the lab’s pneumatic valves, an ECA Current Alarm Trip is used to alarm on low airflow conditions. The ECA comes standard with two SPDT alarm outputs and a TX option (24VDC @ 25mA) that powers the loop powered Airflow Sensor so no additional wiring to a separate 24DC auxiliary power supply is needed. Setpoints for the two alarms are set with front panel potentiometers adjustable from 0-110% of input span. This is very useful for NAMUR compliant type Airflow Sensors as one of the two alarms can be set at >21mA, indicating a failed transmitter condition per NAMUR standards. Field configurable via selectable jumpers, each alarm function can be site configured for high/low and Failsafe/Non-Failsafe relay action. This fast-acting 50msec response time alarm also comes standard with an adjustable deadband capability of 1-20%.

Key Attributes

- Powers and Receives 4-20mA Signal from Airflow Sensor

- Dual field configurable alarms capable of alarming on

NAMUR failure output range from Airflow Sensor - Relays rated 5A, 250VAC

- 50msec response time

- Adjustable deadband for each alarm