Plants that have large fluctuations in flow demand, like potable water plants, often need large flow capacity measuring devices that don’t create large pressure reductions. Venturi tubes are good for these applications, but often if the flow span is large, consistent accuracy across the entire flow range is difficult to achieve. One way to alleviate this is to use double stacked differential pressure transmitters where one DP transmitter is ranged for lower flow rates while the other handles higher flow rates. With this type of configuration, there needs to be some type of smart device involved to automatically switch between transmitters to achieve the best flow accuracy results.

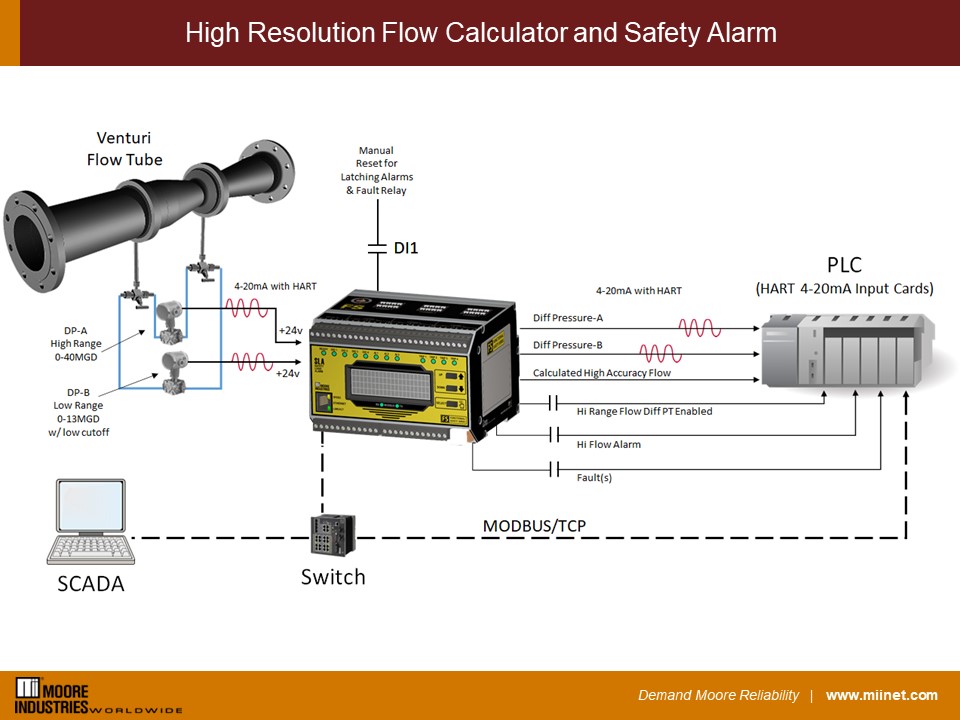

The SLA Safety Logic Alarm provides this decision-making capability and the safety layer of protection needed to alert the plant when demand has reached very high levels. While safety PLCs can accomplish such tasks, there may be a number of reasons why it is not convenient: cost, remote locations, difficulty of programming, or simply that the PLC has no spare memory capacity. This figure shows the SLA installed as a high-resolution flow calculator and safety alarm.

This application includes two differential pressure transmitters connected to the pressure ports of a venturi tube, ranged 0-13 million gallons/day and 0-40 million gallons/day for low and high flow rates respectively. Each of the smart HART differential pressure transmitters is powered by the SLA and their HART signals are passed through to PLC input cards. The SLA primarily serves as a safety logic alarm to notify the PLC when extremely high-demand situations occur.

Additionally, the PLC and SCADA system need to monitor accurate flow rates from the venturi tube. To ensure that the 4-20mA flow signal, and the MODBUS registers also representing the flow rate are as accurate as possible, the SLA is programmed to switch between the differential pressure transmitters, depending on current flow rates. The flow rates are calculated with a differential pressure flow equation via SLA’s advanced configuration settings. When flow reaches a rate of 12.9MGD, the SLA automatically switches to the higher-ranged DP transmitter and automatically switches back to the lower-ranged DP transmitter when flow falls below 12.9MGD. This assures maximum flow rate accuracy across the entire flow rate span.

The SLA also retransmits each of the DP transmitter signals back to the PLC and provides relay outputs when the flow rate exceeds 39MGD, the high-range DP transmitter is selected, or when there are system or input faults captured by the SLA. A digital contact input allows any latched alarms or relays to be cleared. The SCADA system and PLC receive all inputs, outputs, internal equations, variables, alarms, relay status and more via the MODBUS/TCP read-only signal.

Key attributes:

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- -40 to 85 degrees Celsisus ambient temperature operating range

- Simple to configure logic for flow range selection for high-resolution flow calculation

- HART pass-through of pressure transmitter diagnostics to PLC & SCADA system

- Standard MODBUS/TCP protocol sends all process and diagnostic data to PLC

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.