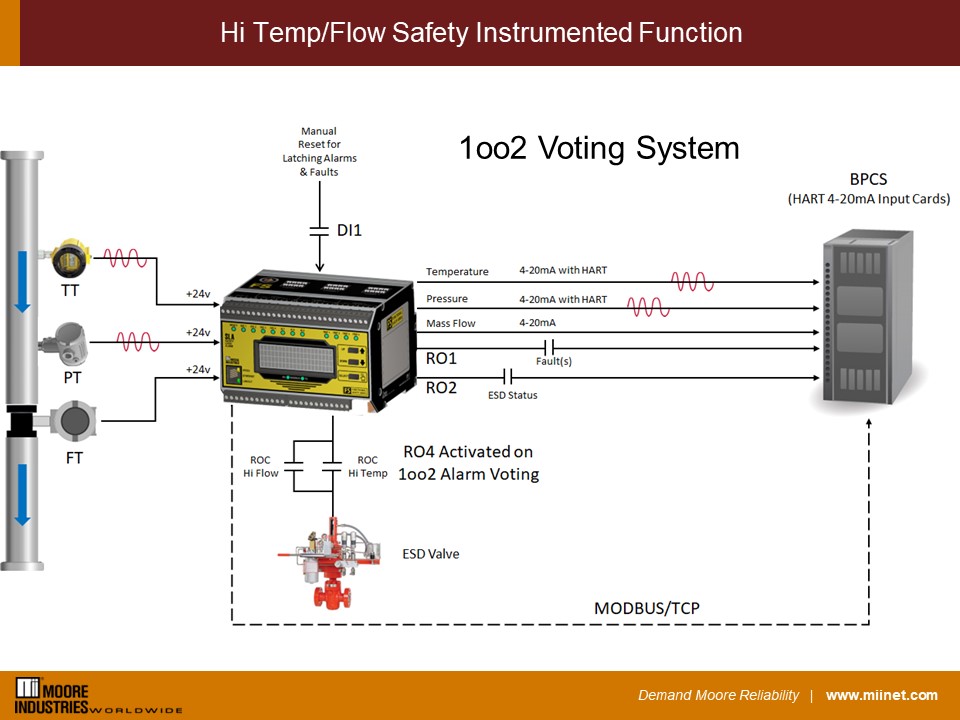

Many critical processes require that flow rates are closely monitored for both product quality and safety. Some of these processes are remotely located in a facility from the BPCS (Basic Process Control System). When calculations like mass flow are required for safety considerations, this can sometimes add precious decision-making time to an already burdened BPCS. With the SLA’s built-in equation editor, calculations can be done remotely and oftentimes faster so process shutdowns can help mitigate dangerous situations. The illustration below shows a SLA Multiloop and Multifunction Logic Solver installed in a high temperature and flow Safety Instrumented System (SIS) application.

This application requires that a temperature, pressure, and volumetric flow signal be used to calculate mass flow to ensure a safe and proper flow rate to the process. Should mass flow or temperature rise too quickly, a dangerous process condition could occur.

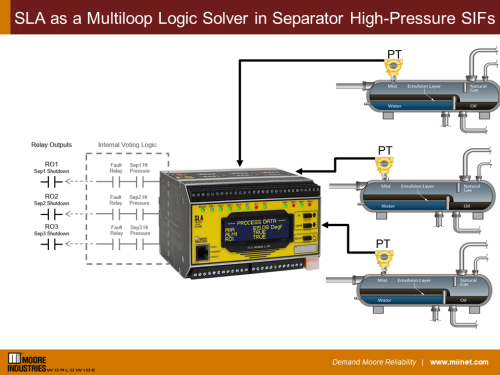

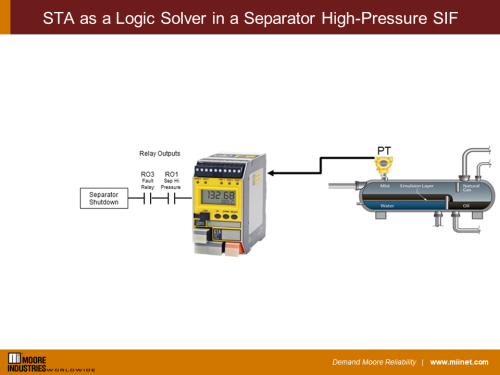

Three loop-powered transmitters are powered and wired into the three isolated SLA input channels. The SLA uses built-in Rate of Change Alarms that monitor mass flow and temperature over time to prevent unwanted surges in process conditions that could lead to a dangerous situation. The SLA uses voting logic (1oo2) to quickly shut down the process in the event of quick increases of mass flow or temperature.

To minimize nuisance trips the alarms are configured as high availability, which means they will not trip if there is an input failure, only when the rate of change event occurs in temperature and/or mass flow. To ensure the integrity of the safety function, input faults along with any system faults are signaled to the BPCS.

The remote BPCS is continually updated with process conditions by receiving three analog outputs from the SLA representing temperature and pressure readings along with the calculated mass flow. The HART signal from the connected temperature and pressure transmitters is passed-through the SLA so any monitoring of HART variables and diagnostics or programming of these connected instruments can be performed. Note that since calculated mass flow is an internally derived output source no HART signal is passed through to the third analog output channel.

Status of the shutdown function and any input or SLA faults are also sent to the BPCS via SLA relay output contacts. An input contact is used to manually reset any latching alarms, faults or relays. A system startup delay is set to suppress flow and temperature alarms which would initiate the shutdown logic. All inputs, outputs, alarms, internal variables, and faults along with various other parameters are transmitted via a secure digital and read-only MODBUS/TCP signal over Ethernet.

Key attributes:

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- -40 to 85 degrees Celsisus ambient temperature operating range

- Rugged aluminum casing which helps dissipate heat and provides protection against radio frequency and electromagnetic noise in harsh environments

- Crital HART pressure and temperature transmitter data passed through SLA to BPCS

- Voting logic and mass flow calculations easily programmed

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.