Search Problem Solvers

Q: Currently we monitor the temperature level in our oven with a thermocouple and let our PLC control the oven. We now need to implement a high-temperature Safety Instrumented Function (SIF). Do we need duplicate temperature sensors and do you have a Functional Safety device that can provide oven shutdown capability on high temperature?

Q: Currently we monitor the temperature level in our oven with a thermocouple and let our PLC control the oven. We now need to implement a high-temperature Safety Instrumented Function (SIF). Do we need duplicate temperature sensors and do you have a Functional Safety device that can provide oven shutdown capability on high temperature?

A: A requirement of the SIF is for a safety function to be independent from the control system with the expectation that the safety loop will not fail should the regular process control loop incur a sensor, controller or any other failure. Therefore, it is recommended you not use the same sensing devices (thermocouple in your instance) for the safety function and control system. Other considerations to factor in are maintenance and proof testing of the SIF. If either affects the control system, interruptions to normal operation during this time will be experienced. If a common sensor is used, then a risk analysis must be performed.(Please refer to IEC61508 standard section 7.4.2.3 and ISA84/IEC61511 Part 1 11.2.10 and Part 2 11.2 for more information.)

To maintain a safe, operable system, SIL (Safety Integrity Level) guidelines state that your SIF would have an independent temperature sensor housed in a different thermowell. For improved safety, use of different technologies for these sensors avoids common cause failures in the control and safety functions; either different types of thermocouples or an RTD if temperature limits allow. Best practice is to duplicate transmission of the safety sensor signals to the control system. Such an arrangement can lead to improved diagnostic coverage by allowing signal comparison between control and safety sensors.

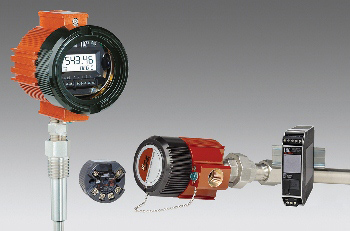

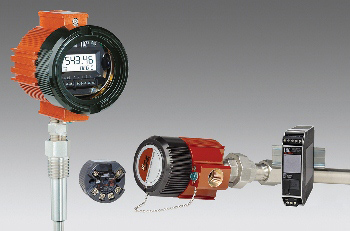

For this SIF, we recommended using products from Moore Industries’ Functional Safety Series which are independently assessed and certified by exida. The STA Functional Safety Trip Alarm can be used to monitor the oven’s thermocouple sensor and includes two user-configurable failsafe process trip alarms. It also has an isolated 4-20mA analog output signal which can be sent to the primary control system for comparison with the process control temperature signal.

If additional process relay outputs are required you can use the SRM Functional Safety Relay Module. The SRM accepts an input from one of the STA process relay outputs and offers three additional relays that can be used to drive other output loads.

The STA Functional Safety Trip Alarm and SRM Functional Safety Relay Module are available with IEC 61508 certificates from exida, safety manuals and FMEDA reports for your SIF calculations.

For more questions regarding application concerns and compatibility, contact us at

E-HELP EXPRESS.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: My Model 330R process monitor with display has configurable threshold output relays that I need to set in order to activate a 125Vdc battery powered circuit which is part of a failsafe control room application. How would I set these up when standard instrument relays are rated at 125/240Vac and 24Vac/dc?

Q: My Model 330R process monitor with display has configurable threshold output relays that I need to set in order to activate a 125Vdc battery powered circuit which is part of a failsafe control room application. How would I set these up when standard instrument relays are rated at 125/240Vac and 24Vac/dc?

A: The Model 330R process monitor threshold alarm relays are ‘compact’ relays designed to activate ‘external intermediate’ relays. High DC voltage (and/or current) switching is always performed on the output contacts of a stand-alone external intermediate relay because high voltage DC switching (opening of relay contacts) creates a sustained high temperature plasma arc. This arc cannot be readily extinguished in a small instrument package, therefore, the relay sacrificially absorbs the excess energy. This ultimately requires replacement of the relay however this is a more economical alternative to replacing a blown panel meter.

A proven solution for the high DC current at high voltages need is to use Form ‘X’ style relays with a built-in magnet (this is a readily available industrial relay product which also comes in a DPDT configuration) as your intermediate relays. The coils of these intermediate relays are driven by the standard voltage/current relays as in the Model 330R series. A quick Internet search of ‘Form X relay schematic’ will provide you with wiring instructions.

A Form X relay has an optional magnet (recommended for DC voltage applications). As the relay opens, a small to moderate sized electrical plasma arc always occurs. The magnet pushes the arc away from a straight line and onto a longer distance pathway. Thus the Form X relay’s mechanical doubling of contact separation distance along with the properties of the installed magnet significantly increase the arc travel distance and more quickly extinguish the DC plasma arc. When wiring for DC switching, be mindful of the polarity of the electrical contact pathway through the magnetic field to ensure that you are extending the arc distance.

To optimally select a Form X relay:

- Perform an Internet search for ‘Form X relay with magnetic blowout’

- Specify a clear relay package referred to as an ‘ice cube’. This permits visual inspection of the relay’s internal movements.

- Specify the relay ice cube package with either a DIN rail socket or a panel mount socket with a retaining clip so the relay does not fall out of the socket as may occur in high vibration applications.

To learn more about the Model 330R, download the datasheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. We have several short thermowells in our process, ranging from 2-inches to 6-inches. Our process is very stable, but we have noticed a temperature measurement shift when the outside air temperature rises or falls. We have tried calibration, but it still doesn’t correct the temperature swing we see. What would you suggest we change that will prevent these temperature swings?

Q. We have several short thermowells in our process, ranging from 2-inches to 6-inches. Our process is very stable, but we have noticed a temperature measurement shift when the outside air temperature rises or falls. We have tried calibration, but it still doesn’t correct the temperature swing we see. What would you suggest we change that will prevent these temperature swings?

A. The most active area of a sensor can be approximated as 4 to 10 times the length of the installed element. As temperatures change outside the process, the upper portion of the sheath is exposed to these fluctuations. This part of the sheath senses a temperature difference then measures it, influencing the temperature along the full length of the sheath. We regularly see this occurrence when calibrating sensors with long sheath length exposed outside of calibration baths. The only way to measure true process temperature is to keep the sheath as short as possible.

Moore Industries manufactures the WORM, a sensor with a very short sheath length of 1.5-inches. Worm sensors are spring loaded to stay at the bottom of the thermowell. They have a faster response time and the lead wires do not measure temperature changes outside the process connection. They do not sense any outside temperature swings and only measure temperature inside the bottom area of the thermowell.

To read more about the WORM, download the data sheet.

You can also download the Get Rid of Rigid White Paper for more information on using the WORM in your process.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We need to combine a new system for reading tank levels with an existing system by replacing a Hagan instrument with a new Rosemount device. However, we need to ensure we can still run an existing 3-27psi pneumatic chart recorder. We’re considering using an I/P, but aren’t sure if the 4-20mA output from the new transmitter can be piggybacked. Is this possible?

Q: We need to combine a new system for reading tank levels with an existing system by replacing a Hagan instrument with a new Rosemount device. However, we need to ensure we can still run an existing 3-27psi pneumatic chart recorder. We’re considering using an I/P, but aren’t sure if the 4-20mA output from the new transmitter can be piggybacked. Is this possible?

A: If the 4-20mA loop can drive the load presented by Moore Industries’ I/P then you can piggyback the output and run your chart recorder. Our model IPT2 (DIN rail mounted) consumes 7.5V of the available loop compliance voltage. Our model IPX2 (field mounted) consumes 5V of the available loop compliance voltage. Both models offer a 3-27psi output.

For additional information, download the datasheet: IPT2 and IPX2.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: You have a product called HART Interface Module (HIM) that will pull the 2nd, 3rd and 4th HART variables from a transmitter signal and create one 4-20mA signal for each. Do you have or know of an instrument that will take multiple 4-20mA signals and output them on one 4-20mA signal as HART dynamic variables? I would like to read three transmitters on one 4-20mA signal by reading the variables on my DCS system.

Q: You have a product called HART Interface Module (HIM) that will pull the 2nd, 3rd and 4th HART variables from a transmitter signal and create one 4-20mA signal for each. Do you have or know of an instrument that will take multiple 4-20mA signals and output them on one 4-20mA signal as HART dynamic variables? I would like to read three transmitters on one 4-20mA signal by reading the variables on my DCS system.

A: We have two products that take multiple inputs and output a HART signal that can be read by a HART host. Those two products are the TCM and the THZ3/TDZ3.

The TCM is a 16 channel input module that accepts multiple temperature, resistance and millivolt signals and offers a HART output or a MODBUS RTU output. For 4-20mA inputs the TCM accepts them across a resistor or shunt input as a mV input. Those signals can then be read by a HART host using a custom HART command. For a MODBUS RTU output a separate HART to MODBUS converter, called the HMC, is used. For more information on the TCM and HMC (which together comprise the TCS) download the TCS data sheet.

The THZ3/TDZ3 Smart HART Temperature Transmitter can accept two (not three) 4-20mA

signals and write them to two of the HART dynamic variables riding on the analog 4-20mA

output.

A wiring diagram showing how to wire the THZ3 to accept two 4-20mA input signals is available in the Installation Manual which you can download here. For more information, download the THZ3 data sheet.

For more information on the HIM, download the data sheet.

Q. We have been using 3-wire RTDs in our process for years and are required to check the calibration once every 6 months. Each time we have checked the sensors we’ve noticed they have drifted. This requires us to re-calibrate our temperature transmitters. Do you have something you can suggest to help us reduce the drifting problem we regularly see in these sensors?

Q. We have been using 3-wire RTDs in our process for years and are required to check the calibration once every 6 months. Each time we have checked the sensors we’ve noticed they have drifted. This requires us to re-calibrate our temperature transmitters. Do you have something you can suggest to help us reduce the drifting problem we regularly see in these sensors?

A. The problem with 3-wire RTDs is that the lead wires build up small amounts of corrosion causing a lead wire imbalance which results in measurement errors. If these are Platinum 100 ohm RTDs, just one ohm of resistance change on any lead wire can represent a +4.7°F degree error. We suggest using 4-wire RTDs which compensate for unequal resistance in the lead wires. For this to be an option your temperature transmitters need to accept a true 4-wire sensor input. Some temperature transmitters, PLCs, and DCS input cards only accept 3-wire RTDs. Others indicate a place to connect a fourth wire, but do not use it for measurement.

You can also use Class A RTDs with 4 wires and a transmitter that can accept and be calibrated with a 4-wire RTD. Our Class A element RTDs with a .06% accuracy have been cycled for 1000 hours, and will hold their accuracy for a 5 year period.

You can learn more about using 3-wire and 4-wire RTDs in the white paper: A Practical Guide to Improving Temperature Measurement Accuracy.

These Moore Industries temperature transmitters are designed to accept true 4-wire RTDs: RIY, STZ, TCS, TDY, TFZ, THZ, THZ3/TDZ3, TPZ, TRY, TRX. For these and other Moore Industries temperature solutions, visit our Temperature Sensors, Transmitters and Assemblies page.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I would like to use either FDY/PRG/4-20MA/12-42DC [HPDN] or FDY/PRG/4-20MA/12-42DC [BH2NG] and I want to install it in a control panel enclosure rated Type 4X. I need to ensure it is suitable for Class I, Div 2. Which one is the best solution?

Q: I would like to use either FDY/PRG/4-20MA/12-42DC [HPDN] or FDY/PRG/4-20MA/12-42DC [BH2NG] and I want to install it in a control panel enclosure rated Type 4X. I need to ensure it is suitable for Class I, Div 2. Which one is the best solution?

A: The FDY/PRG/4-20MA/12-42DC [HPDN] without the BH2NG enclosure is Class I, Div 2 rated. It meets the Div 2 requirements when installed in your Type 4 box. You can download the certificate here.

The FDY/PRG/4-20MA/12-42DC [BH2NG], is an explosion proof transmitter approved for use in Class I, Div 1 hazardous areas. This is the same FDY device except it is housed inside the explosion proof/flameproof BH2NG enclosure. This BH2HG enclosure is also rated Type 4X & IP66 which means that it offers sufficient environmental protection to allow it to also be classified as a Class I, Div 2 or Non-Incendive device. The FDY/PRG/4-20MA/12-30DC/-ISF with the [HPDN] housing designation or enclosed in a BH type housing carries intrinsically-safe approvals.

Download the FDY datasheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. I have a temperature application that requires a 12-inch thermowell which can withstand a high temperature of 2,000°F. Most of what we have been using becomes brittle and breaks off at the tip. What would you suggest we use, and what type of sensors do you have that will work for us?

Q. I have a temperature application that requires a 12-inch thermowell which can withstand a high temperature of 2,000°F. Most of what we have been using becomes brittle and breaks off at the tip. What would you suggest we use, and what type of sensors do you have that will work for us?

A. We have several different types of metals we can suggest with maximum temperatures up to 2,160°F. Materials that will work well for the thermowell in your application are SS446, SS310, and Inconel 600.

For the sensor type, we recommend a thermocouple Type “K” with Inconel 600 material for the sheath. Also, using 2-inches of thermal-lagging for the thermowell will reduce heat going into the head.

If possible, remote mount the temperature transmitter away from the process connection. Even though Moore Industries temperature transmitters are rated up to 185°F, it could get too hot inside the head if it were mounted directly on top of the process. If you must mount the transmitter near the process connection, we suggest using a stainless steel housing and a ceramic terminal block to terminate the sensor at the process.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have an R-BOX in a Class 1 Div 2 location with a 120VAC instrument inside. Is this enclosure rated for this atmosphere? It does not appear to have a very good seal for this environment.

Q: We have an R-BOX in a Class 1 Div 2 location with a 120VAC instrument inside. Is this enclosure rated for this atmosphere? It does not appear to have a very good seal for this environment.

A: The R-BOX was designed to meet a Type 4X and IP66 rating, which is suitable for housing a Div 2 approved device. The hazardous area protection is provided by the non-incendive nature of the Div 2 rated device mounted inside. The enclosure simply needs to provide protection from the ambient elements or other flying conductive material.

Learn more by downloading the R-BOX datasheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. We want to measure bearing temperature in our motors to alert us of overheating. We have used a type of sensor which inserts into the side of the motor, but they leak and fail often. We would like to put something on the surface of the motor outside of the bearing housing, but we do not want something welded to the housing. What can you suggest?

Q. We want to measure bearing temperature in our motors to alert us of overheating. We have used a type of sensor which inserts into the side of the motor, but they leak and fail often. We would like to put something on the surface of the motor outside of the bearing housing, but we do not want something welded to the housing. What can you suggest?

A. The best solution for your application is a WORM sensor with a Magnetic Pad (-MPAD). The -MPAD has 40lbs of attraction and will hold up to a vibrating surface. We also suggest adding our 30G option to the RTD, in order to protect the RTD element inside the sheath from high vibration during motor operation. Standard fixed length sensors cannot withstand this vibration over time. The -MPAD with WORM sensor is easy to install on any ferrous metal surface.

Download the RTI-3 datasheet for more information.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am evaluating the SIX 2-wire Signal Isolator and Converter. Is this device auto-calibrated or will we need to calibrate it ourselves? Does it require two separate power supplies? The specs state that the output is loop powered but I am not clear on the input. Also, is it a problem if we supply both the input and output with the same power source? In our case, it would be the 53.5VDC power supply in the loop currently. We would need to run a parallel path. The input is intended to be a 4-20mA.

Q: I am evaluating the SIX 2-wire Signal Isolator and Converter. Is this device auto-calibrated or will we need to calibrate it ourselves? Does it require two separate power supplies? The specs state that the output is loop powered but I am not clear on the input. Also, is it a problem if we supply both the input and output with the same power source? In our case, it would be the 53.5VDC power supply in the loop currently. We would need to run a parallel path. The input is intended to be a 4-20mA.

A: The SIX is provided pre-calibrated from the factory for the input and output indicated in the model number. The device has potentiometers accessible on the front panel for making adjustments to the zero and span.

The SIX derives its operating power from the voltage that is applied to its output. It consumes 12V of the available voltage applied to its output. The SIX accepts a voltage or current input. If the input is 4-20mA, then the SIX will add 50 ohms of impedance to that loop.

Regarding supplying both the input and output with the same power source, the primary purpose of the SIX is to provide input to output galvanic isolation. Using the same power supply for both would defeat that isolation.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have been using your SPA series temperature transmitters in our hydroelectric power plants with excellent results. These devices have high protection against electromagnetic interference. We would like to purchase temperature transmitters for head mounting and rail mounting that have the same high level of isolation and protection against electromagnetic interference. The sensors are 10 Ohm Cu three wire RTDs and they represent the temperature of generator windings in the hydroelectric power plant.

A: Model SPA/TPRG/2PRG/U/-AO [DIN] provides 0.25 mA RTD excitation current. If it is performing well then our PC configurable temperature transmitters, which have the same excitation current, should also perform well. In that case we recommend the TRY series. The head mount style is model TRY/PRG/4-20MA/10-42DC [LH2NS]

If your SPA has the SP2 option instead (Model SPA/TPRG/2PRG/U/-AO-SP2 [DIN] ), that option provides 5mA of excitation current to the 10 ohm RTD instead of the usual 0.25mA. This ensures that a robust input signal from the RTD to the SPA resists interference from the generator’s very strong electro-magnetic fields.

The choices available for a head mounted transmitter with similarly high current RTD excitation are limited. Bear in mind that the objective when designing RTD temperature transmitters is to reduce the excitation current as much as possible to minimize self-heating of the RTD, thereby maximizing the measurement accuracy.

Also due to the reduced power budget of loop powered transmitters there isn’t sufficient power available for the 5mA excitation current of the SP2 option.

A possible solution is one of our older analog loop powered transmitters, the RBX series, which has a relatively high excitation current of 1mA. The RBX, however, is a strictly analog design and must be specified according to the intended resistance range instead of temperature span. For example, for 10 ohm Cu and 0-200 deg C, the resistance is 9.035 to 16.776 ohms. The span is 7.741 ohms. The 7.741 span falls within the 3W5-10 input range.

The head mounted model number is: RBX/3W5-10/4-20MA/12-42DC/-EZ9 [BH2NS].

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I need confirmation that the THZ2 is a functional like-for-like replacement for the THZ and that basically it will perform the same.

Q: I need confirmation that the THZ2 is a functional like-for-like replacement for the THZ and that basically it will perform the same.

A: With the exception of the THZ/PRG/4-20MA/12-42DC [DH2NG], which has an integral display, the THZ2 has all of the functions of the THZ and the same form and fit.

However, we suggest you consider the newer THZ3, since the THZ2 is being phased out (although it will continue to be available while supplies last). The THZ3 has all of the functions of the THZ2 and the same form and fit. The THZ3 offers additional functionality over the THZ2, can accept two sensor inputs, and utilizes PACTware for PC configuration in addition to HART programmability.

Other features found in the THZ3 that are not included in the THZ are:

- Backup and Fail-Over Protection allows either of the sensors or inputs to be designated as the primary measurement, with the secondary input acting as the backup sensor in case of primary sensor failure.

- Average and Differential Measurement allows you to average the two input measurements or select the differential (A-B or B-A) or absolute differential between the two inputs.

- High-Select and Low-Select Feature enables the transmitter to continuously monitor two separate inputs and designate either the highest or lowest input to represent the analog output.

- Dynamic Variable Mapping permits the user to assign either input or the calculated result of inputs to any of the four HART variables (PV, SV, TV or QV) that can be read by any HART compatible host system.

- Smart Range Alarms offer four HART alarms set to any input or calculated input that detect when the variable is within or outside user preset limits.

- High Availability Option enables the user to select how the AO behaves when there is an input failure or out-of-range value detected by the transmitter. This prevents nuisance alarms on startups or batch process shutdowns.

Download the THZ3 data sheet.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: You have a product called HART Interface Module that will pull the 2nd, 3rd and 4th HART variables from a smart HART transmitter and create one 4-20mA signal for each. Do you have or know of an instrument that will take three 4-20mA signals into it and place themdin on one 4-20mA signal as the 2nd, 3rd and 4th variable? I would like to read three transmitters on one 4-20mA signal by reading the variables on my DCS System.

Q: You have a product called HART Interface Module that will pull the 2nd, 3rd and 4th HART variables from a smart HART transmitter and create one 4-20mA signal for each. Do you have or know of an instrument that will take three 4-20mA signals into it and place themdin on one 4-20mA signal as the 2nd, 3rd and 4th variable? I would like to read three transmitters on one 4-20mA signal by reading the variables on my DCS System.

A: We have three products that can take multiple analog inputs and provide that signal data in the form of HART protocol. Those products are the TCM and THZ3 / TDZ3, which are temperature input devices that can take a 4-20mA input across a resistor (shunt) as a mV input.

The TCM is a 16-channel temperature input module that can be polled by a HART master using a device-specific HART command. This HART command retrieves all 16 channels of PV data in one HART message packet.

The THZ3 Dual Input Smart HART DIN-Rail or Field Mount Temperature transmitter can accept two (but not three) 4-20mA signals and write them to two of the HART dynamic variables riding on the analog 4-20mA output signal.

The TDZ3 has the same functionality as the THZ3 but includes a display and can be field mounted in hazardous or non-hazardous areas or mounted on DIN-Rail.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am looking to take a signal from an analyzer and send the analog output signal to four different locations. Do you have a product that can help me with this?

Q: I am looking to take a signal from an analyzer and send the analog output signal to four different locations. Do you have a product that can help me with this?

A: We offer a 4-channel output loop powered isolator and a line powered single input to dual output isolator.

If the receivers at the four locations can supply loop voltage to their respective 4-20mA inputs, then the 4-channel output loop powered MIX isolator (Model: MIX/4X4-20MA/4X4-20MA/12-42DC [DIN]) will work. Wire your 4-20mA signal in series to the four inputs of the MIX.

If the receivers at the four locations have passive (sinking) 4-20mA inputs, then you can either use two of the line powered ECT splitters or two of the dual channel MIT isolators (Models: ECT/4-20MA/2X420MA/117AC/-TX [DIN] or MIT / 2XPRG / 2X4-20mA / U [DIN]). Wire your 4-20mA signal in series to the inputs of the two ECT/MITs.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I want to replace a THZ Temperature Transmitter (Model THZ/PRG/4-20MA/12-42DC [DIN]) with a CPT PC-Programmable Temperature Transmitter (Model CPT/TPRG/0-20MA/117AC/-C-RF [DIN]). The THZ unit we are replacing gets its power from the 4-20mA current loop while the CPT unit is going to be powered by 120Vac. Does the CPT need to be specified as "source" or "sink" to work as a drop-in replacement for the THZ unit?

Q: I want to replace a THZ Temperature Transmitter (Model THZ/PRG/4-20MA/12-42DC [DIN]) with a CPT PC-Programmable Temperature Transmitter (Model CPT/TPRG/0-20MA/117AC/-C-RF [DIN]). The THZ unit we are replacing gets its power from the 4-20mA current loop while the CPT unit is going to be powered by 120Vac. Does the CPT need to be specified as "source" or "sink" to work as a drop-in replacement for the THZ unit?

A: The default version of the CPT provides voltage on its output (source). If you would like the output to be passive so it can be wired to an active (voltage supplied) input, specify the "-SINK" option. The CPT will still require 120Vac power on the power terminals.

Note that the newer two-wire output loop powered THZ3 Dual Input Smart HART Temperature Transmitter (Model THZ3/PRG/4-20MA/12-42DC [DIN]) is now available.

Q: My concern is that we will damage the unit or the equipment it is connected to it if we specify the wrong type of output. This unit will be connected to an Allen Bradley 4-20mA analog input module. The previous THZ device got its power from the analog input module so I believe the correct specification would be "sink" for the CPT. Is this correct? Also, can the "source" or "sink" option be changed in the field or does this have to be set at the factory?

A: You are correct that you will need to choose the "-SINK" option on the CPT. The choice of "source" or "sink" for the CPT must be specified in the model number and supplied from the factory that way. It cannot be field changed. Your complete model number for this application would be: CPT/TPRG/0-20MA/117AC/-C-RF-SINK [DIN]. Note that you have also selected an auxiliary alarm contact and enhanced RFI/EMI protection.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I need to use the STA Safety Trip Alarm in a hardwired panel. Is it possible to configure two different levels of alarm for each of two relays in the STA, in order to have two different trips (one for each relay)?

Q: I need to use the STA Safety Trip Alarm in a hardwired panel. Is it possible to configure two different levels of alarm for each of two relays in the STA, in order to have two different trips (one for each relay)?

A: Only one set point can be assigned to each alarm relay of the STA. However the dead-band is adjustable from 0% to 100% of the input span. Therefore you can specify one signal level at which the relay engages and another for when it disengages. If your input signal is 4-20mA, you can connect it in series to the inputs of two STAs in order to obtain 4 independent relay/setpoints.

Q: To clarify my situation: if I have a 0 to 100 bar transmitter, can I trigger Relay 1 at 25 bar and Relay 2 at 75 bar? We need to do this in order to shut down two different pieces of equipment at these pressure levels.

A: This is a typical function of the STA. One relay setpoint is often used for a warning at one level while the second relay setpoint is used for shutdown at the next level.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We are in need of a signal converter that converts a 4-20mA logarithmic signal into a 4-20mA linear signal. We need one input and one output per device. Do any of your devices perform this function?

Q: We are in need of a signal converter that converts a 4-20mA logarithmic signal into a 4-20mA linear signal. We need one input and one output per device. Do any of your devices perform this function?

A: We offer several models of signal converters which have look-up table linearization/characterization capability.

The SIY is an output loop-powered unit that can be configured for up to 85 ordered pairs. With this model, each ordered pair must be keyed in using the provided configuration software.

The CPT is a line-powered model that can be configured for up to 128 ordered pairs. The ordered pairs are computed with a spreadsheet, saved as a two column CSV file and then loaded into the provided configuration software. The configuration is then loaded into the CPT.

With both models you specify the X and Y values so you can cluster points at the most non-linear part of your table.

With both models you specify the X and Y values so you can cluster points at the most non-linear part of your table.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We are a boiler/burner company dealing with a rising amount of computer-based burner controls. We have installed several and have some blowers that are controlled by VFDs (Variable Frequency Drives). We have run into issues with noise on certain systems. We get occasional problems with 4-20mA feedback from the VFD despite going through the proper grounding techniques. We are wondering if installing an opto isolator on the feedback loop might eliminate our issue. We have used the SIX Signal Isolator many times on the signal going to the VFD to offset impedance issues on the VFD. Can we put an opto isolator on both signals?

Q: We are a boiler/burner company dealing with a rising amount of computer-based burner controls. We have installed several and have some blowers that are controlled by VFDs (Variable Frequency Drives). We have run into issues with noise on certain systems. We get occasional problems with 4-20mA feedback from the VFD despite going through the proper grounding techniques. We are wondering if installing an opto isolator on the feedback loop might eliminate our issue. We have used the SIX Signal Isolator many times on the signal going to the VFD to offset impedance issues on the VFD. Can we put an opto isolator on both signals?

A: Whether the SIX or another isolator will cure your problem depends on the nature of the noise and how the loop is energized. Sometimes you can install an isolator without additional analysis and see if it works.

If you have data about the noise, compare it to the noise rejection specification of the isolator. For example, the Common Mode Rejection for the ECT-DIN Signal Isolator exceeds 95dB @ 60Hz with a limit of 1500 Vrms.

When selecting the appropriate isolator, take into account which device is providing the loop voltage on the input and output sides. Per the ECT datasheet, you can see that it is available as an output loop powered, input loop powered or line powered device.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am looking for a device to create a temperature switch. I currently use a simple temperature switch with a 230°F setting, but at times the temperature of the unit goes over 400°F briefly and destroys the switch. I need to be able to hook a thermocouple up to the device and program a setpoint (with no display required) and have a set of dry contacts open when the temperature rises above the setpoint.

Q: I am looking for a device to create a temperature switch. I currently use a simple temperature switch with a 230°F setting, but at times the temperature of the unit goes over 400°F briefly and destroys the switch. I need to be able to hook a thermocouple up to the device and program a setpoint (with no display required) and have a set of dry contacts open when the temperature rises above the setpoint.

A: Our model CPA PC-Programmable Alarm can accept a thermocouple or RTD input and trip a relay based on the setpoint that you have configured. It can be configured using our software and a USB cable.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q. We would like to use the ECA-DIN in a seismic application. In a worst case scenario of an earthquake, the ECA-DIN must retain its position. We are concerned about the robustness of DIN rail mounting. Is the ECA available with a bolt down option?

A. We can supply the ECA with side flanges for more robust gearplate mounting instead of the usual DIN rail mounting.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have an existing Rosemount 1151DP tied to a Provox DCS. We also have a Moore Industries DDA 4-Wire Current and Voltage Alarm in the system to provide a Flow Switch Low and Flow Switch High interlock to our gas supply valves. Will newer products from Moore Industries provide more – or better – protection than the DDA?

A: The STA Safety Trip Alarm and SPA2 Site Programmable Alarm have alarm functions and can be used instead of the DDA. Both products have FMEDA reports which define the Probability of Failure on Demand and can provide a better degree of protection than the DDA. Additionally, the HIM HART Interface Module has alarming functionality that could also be used with the 1151DP transmitter.

The STA monitors the analog signal and is specifically designed for IEC 61508 applications. It is approved by exida for use in Safety Instrumented Systems (SIS) up to SIL 2 and in redundant architectures (1oo2, 2oo3, etc.) up to SIL 3.

Like the STA, the SPA2 can also monitor the analog signal and provides up to four alarms, a display, and an optional 4-20mA retransmission. The SPA2 is our most popular alarm choice for loops that are not specifically designed in accordance with IEC 61508/61511The HIM monitors the digital component of a HART signal and can be specified with up to two optional relay outputs, which can be configured for signal level alarms or for a number of HART status bits. It can be used to provide diagnostic coverage for a HART transmitter since it monitors the transmitter’s status bits.

Do you want more information? Look up a data sheet to download. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I need a 4-wire isolator and want to see if your MIT Multi-Channel Signal Isolator will work in my application. I have several 4-wire transmitters where I need to split and isolate the output signal to receivers that are passive (not powered). Will the MIT work provided that I supply 24Vdc power to the unit?

A: The MIT appears to be a perfect fit for your application. MIT’s input is passive, so it is compatible with the active output of a 4-wire transmitter. Because its outputs are active, they are compatible with the passive inputs of the receiver devices. In addition, it uses a universal power input, so it will accept 24Vdc power.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am looking for a differential temperature transmitter. We have used the SPT in the past and know that it will work, but I don’t know if you can use two inputs of two different 4-wire RTDs with the SPT.

A: The SPT has only four input terminals; therefore the number of RTD wires is limited. For differential temperature, one RTD can be a 3-wire and the other RTD can only be a 2-wire. The lead length compensation wire of the 3-wire connection compensates for the lead length of both RTDs. This is only useful if you make sure that all five wires have identical resistance.

To answer your question, you may use two 4-wire RTDs, but you cannot connect all of the wires unless you do it as described above. Wiring details are shown in Figure 17 of the installation manual.

A better option is to use our DIN rail mounted THZ3 HART temperature transmitter, a new model which can accept two three-wire RTDs and provide a differential measurement output. The configuration of the THZ3 is done by utilizing DTMs with PACTware on your PC or by using a HART compatible handheld device or HART host.

Details about the input connections of the THZ3 are in Figure 2.2 of the installation manual.

Model Example: THZ3/PRG/4-20MA/12-42DC [DIN]

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: I am interested in an ECA alarm unit, model #: ECA/4-20MA/DH1H1/24DC/DIN. I have three questions:

1. I have a need for three different trip setpoints based on the same transmitter input. How can I accomplish this with the ECAs? Can I use two ECAs using the second ECA with a 1-5VDC input or can the 4-20mA signal be run in series through both ECA inputs?

2. Do I need to specify the -RF option to get the RFI protection? And is the testing for both radiated and conducted susceptibility (RS103, CS114, CS115)? Is it possible to see the test report for the EMI/RFI testing?

3. Is DIN-rail the only mounting option?

A: To answer your three questions:

1. Your 4-20mA signal can be connected in series to the inputs of more than one ECA, each of which with a 50 ohm load on the loop. Alternatively, you can use a SPA2 Limit Alarm Trip (Model #: SPA2/HLPRG/4PRG/U [DIN]) which has four setpoint relay outputs.

2. The ECA-DIN has RFI/EMI Protection to 10V/m, 20-1000MHz for which the trip point would not be affected by more than 0.1% of span. It conforms to the following EMC specifications:

EN50081-2, 1993, Generic Emissions Standard, Industrial Environment.

EN50082-2, 1995, Generic Immunity Standard, Industrial Environment.

EN61010-1, 1995, Safety requirements for electrical equipment for measurement and control use.

3. Both the ECA-DIN and the SPA2 are designed for DIN rail mounting; however, we also offer them with options for flange mounting.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.

Q: We have been using Moore Industries DCA series switches for some time. Is there a like-for-like digital microprocessor-based replacement available?

A: The SPA2 series is a microprocessor-based design with all of the capabilities of nearly any permutation of the DCA. It does have a different form and fit, so we will need to know the complete model number of your DCA unit in order to recommend a SPA2 model.

The most common type of DCA mounts to a back panel with four screws, such as model DCA/4-20MA/DH1L1/117AC [UB]. We can provide the SPA2 with the same mounting bracket so that it fits the same footprint and hole pattern.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.