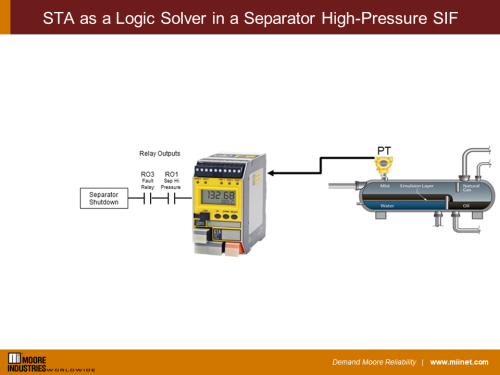

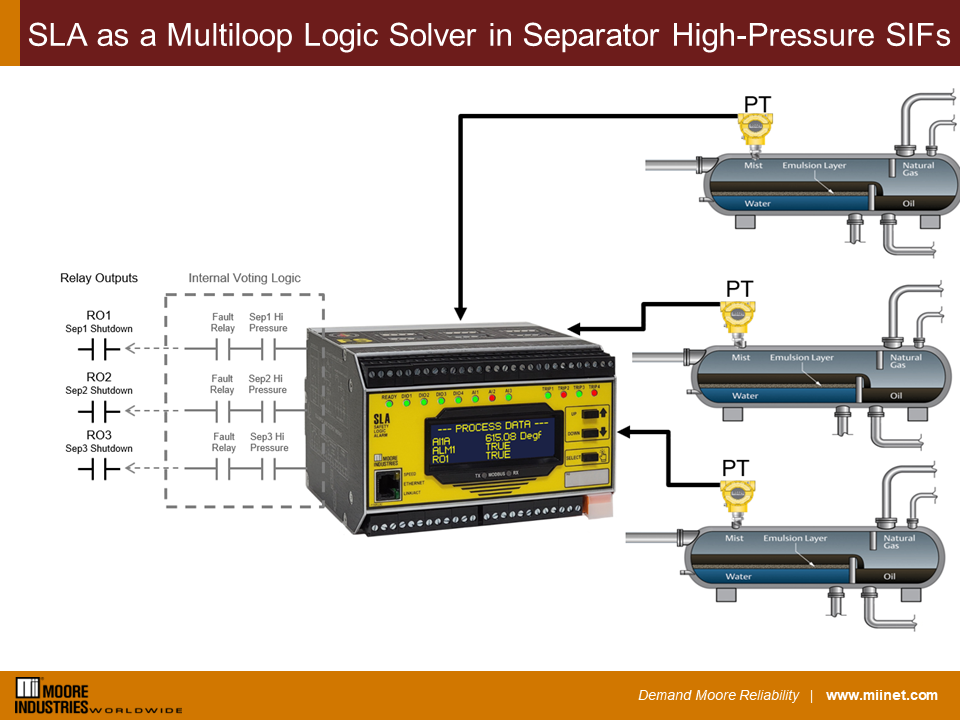

There are three separators located at the site that need safety protection applied. Each separator has a pressure transmitter attached to a logic solver, which sends pressure readings via a 4-20mA signal. When pressure in the separator reaches extremely high-pressure levels, this is considered a dangerous condition. To attain high integrity of the separator pressure SIF, the diagnostics of the logic solver shall be monitored continuously. Should the logic solver experience any faults or separator pressure breach its high-pressure limit, a shutdown of the separator should take place.

All separator SIFs require that logic solvers be IEC 61508 certified and SIL 2 capable. Due to limited power supply and remote locations, the logic solver shall power the connected pressure transmitter and be suitable for outdoor installation and harsh environments.

Separator Pressure SIF Requirements

- Logic solvers used for each separator SIF must be IEC 61508 certified and SIL 2 capable.

- The logic solver must be able to provide power to the pressure transmitter on the separator.

- Outdoor installation location requires an ambient operating temperature range of -40 to 85°C.

- A High-Pressure alarm needs to be configured for shutdown initiation.

- Logic solver internal diagnostics/faults must be continuously monitored.

- Logic solver shall shutdown separator operation in the event of high pressure or logic solver fault.

The SLA is an exida-certified SIL 2/3 capable Multiloop Safety Logic Solver and Alarm that performs as a single or multiloop logic solver incorporating enhanced math, voting, and logic capability to act on potentially hazardous process conditions in a SIS. The SLA is an ideal logic solver for this application example given its SIL 2/3 capability and multiloop ability to handle up to three safety loops. The SLA accepts six analog inputs, four discrete inputs and includes auxiliary 24V power for connected transmitters. While redundant pressure sensors are not required for this specific application, the SLA could be configured to monitor two pressure inputs per separator with automatic failover capability, should one pressure sensor fail.

Unlike single-loop logic solvers that have limited alarm capabilities, the SLA includes 16 configurable internal alarms that can be assigned to any, or multiple, of the SLA’s four relay outputs. Voting scenarios can also be easily implemented with any combination of internal alarms, discrete inputs, internal logic statements, faults, or even relay outputs. This along with the SLA’s math and logic capability, provides an extensive array of alarming or safety shutdown schemes.

As was required with the STA single loop logic solver, the logic solver’s faults must be continuously monitored to provide the desired safety availability. Fortunately, the SLA has the ability to internally monitor the status of the fault relay and use it in any voting logic, equation, or alarming scheme necessary. High-pressure internal alarms are configured in the SLA for each of the three separators. One additional internal alarm is configured to monitor the SLA’s fault relay should any faults or failures be detected. Now that four internal alarms have been configured, each of the three separator SIFs can utilize a dedicated failsafe relay output to initiate high-pressure separator shutdown.

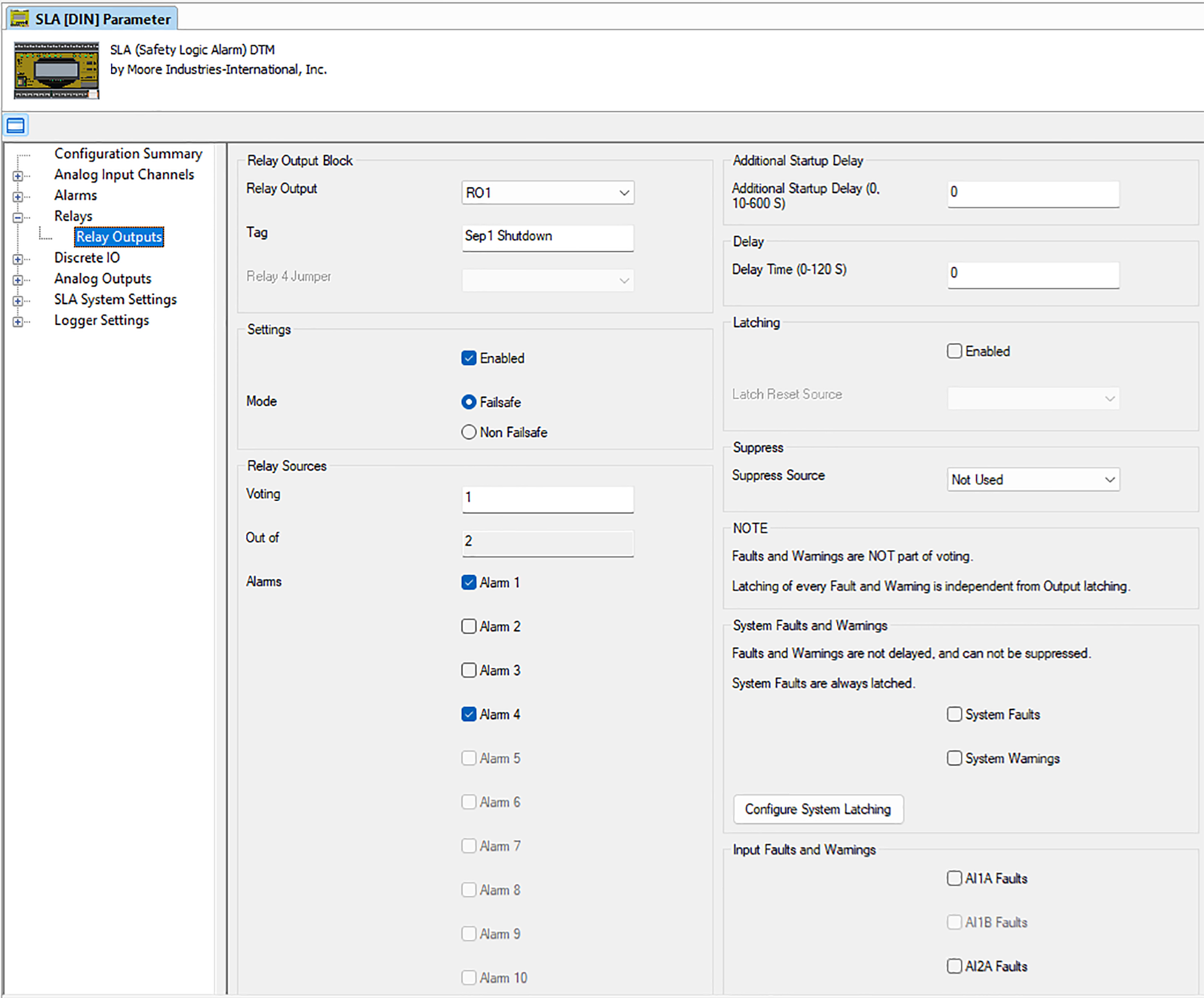

As illustrated above, relay outputs 1-3 use voting logic within the SLA to determine if a high-pressure condition or SLA fault has been detected. If either scenario exists, the respective failsafe relay output is triggered, and separator shutdown follows. While three independent single-loop logic solvers were required in the prior example, the multiloop and internal voting capability within the SLA allows for one logic solver to be used for all three high-pressure separator SIFs, thus reducing cost, maintenance, and wiring complexity.

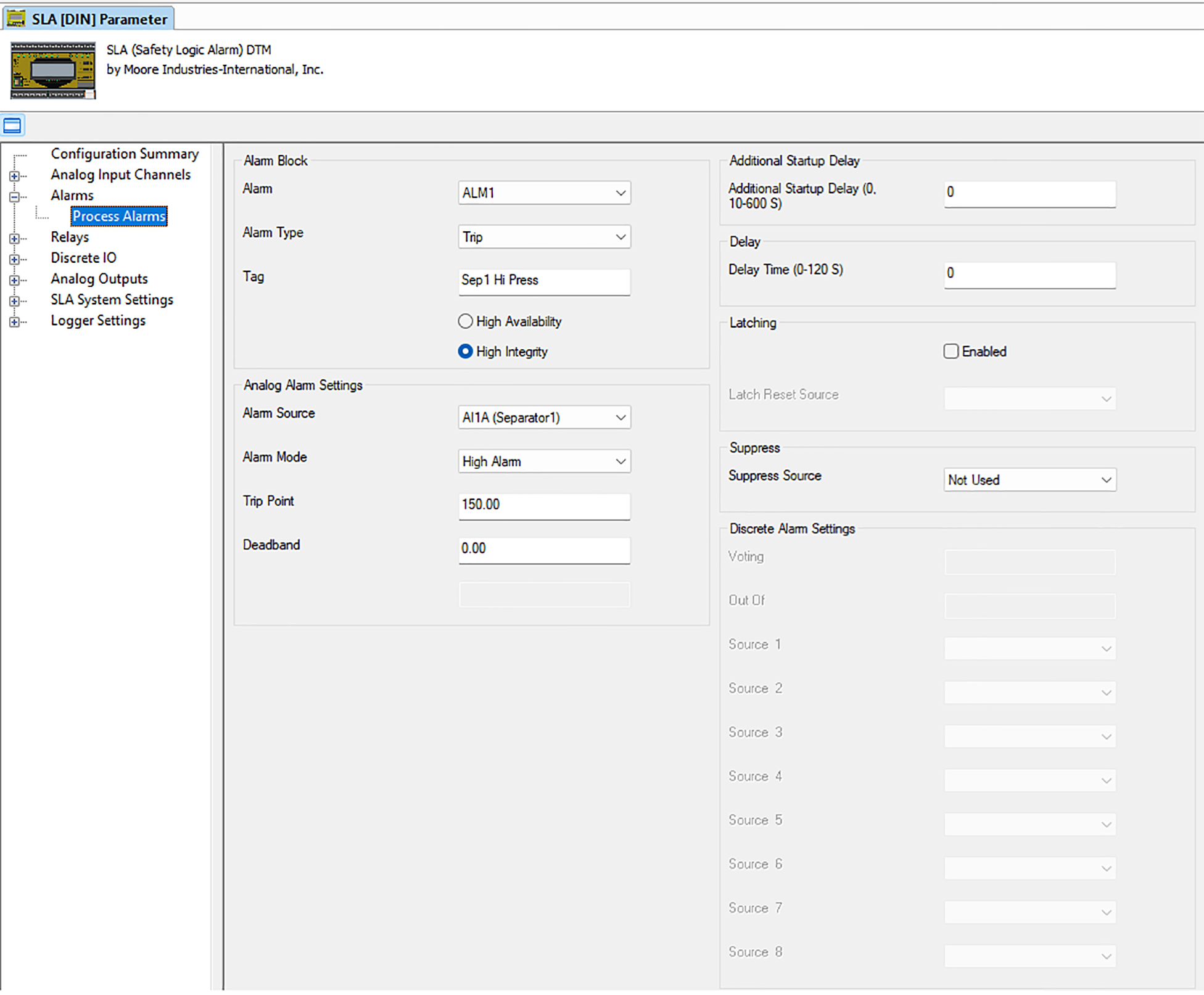

The SLA was designed to be more capable, powerful, and flexible than single-loop logic solvers, but easy to program. While safety PLCs can certainly handle much higher point counts than the SLA, many safety practitioners have applications that require just a few loops or smaller point counts but don’t need or want the complexity of programming and maintaining a safety PLC. To alleviate these concerns, all SLA configuration is accomplished in an open and royalty-free DTM/FDT environment. FDT programming environments such as PACTware are free to end users and offer simple and straightforward screens for device configuration. To demonstrate the SLA’s ease of configuration for this application example, we have provided a few PACTware screenshot examples below.

To configure the SLA as a logic solver for three separators, PACTware is used to create the high-pressure alarms and voting logic required to initiate safety shutdown. Outlined below are the key configuration requirements and associated PACTware screenshots demonstrating the SLA’s ease of programming and setup.

SLA Key Configuration Requirements for High-Pressure SIF

Required separator alarms:

Separator 1

• Create ALM1 = Hi Pressure Alarm

Separator 2

• Create ALM2 = Hi Pressure Alarm

Separator 3

• Create ALM3 = Hi Pressure Alarm

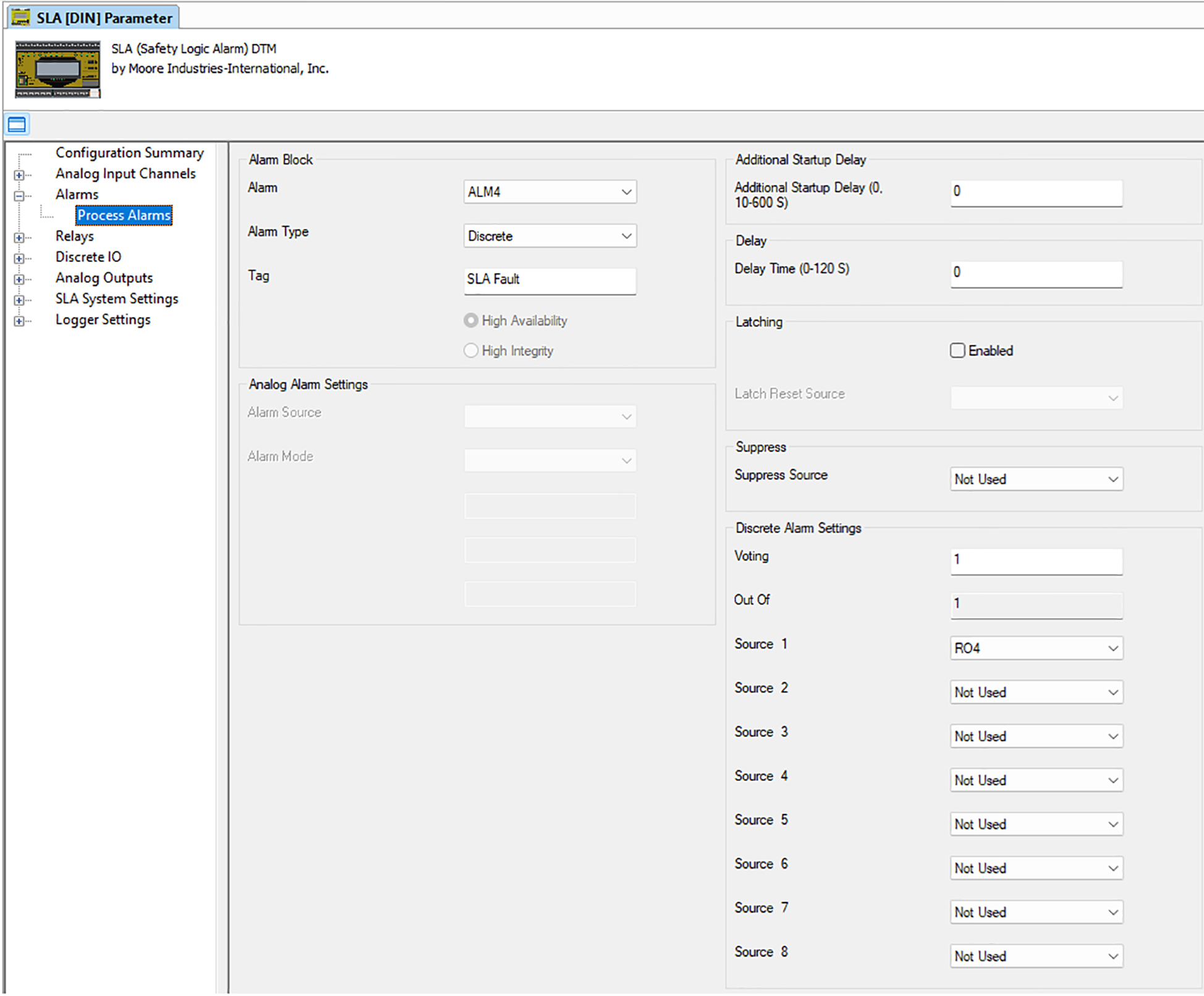

SLA Fault Alarm

• Create ALM4 = Set Alarm Type as Discrete, 1oo1 Voting, Source 1 is RO4 (SLA

Fault Alarm)

Required separator shutdown outputs:

Separator 1

• Create RO1 = 1oo2 voting on ALM1 (High Pressure) or ALM4 (SLA Fault Relay)

Separator 2

• Create RO2 = 1oo2 voting on ALM2 (High Pressure) or ALM4 (SLA Fault Relay)

Separator 3

• Create RO3 = 1oo2 voting on ALM3 (High Pressure) or ALM4 (SLA Fault Relay)

Key attributes of the SLA:

- Simple to configure 2oo3 voting alarm with check boxes and pull-down menus

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- HART pass-through of pressure transmitter diagnostics to RTU/PLC

- SLA provides 24Vdc power to all three pressure transmitters for ease of wiring

- -40 to 85 degrees Celsius ambient temperature operating range

- Standard MODBUS RTU protocol sends all process and diagnostic data to RTU/PLC

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or use our online form.