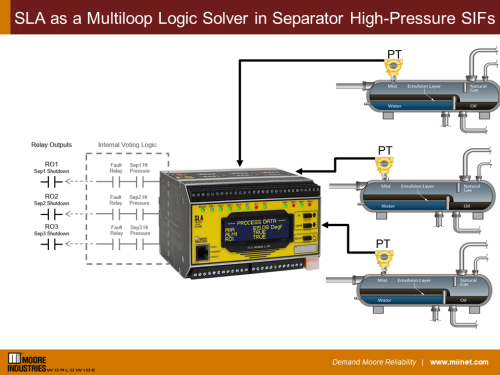

There are three separators located at the site that need safety protection applied. Each separator has a pressure transmitter attached to a logic solver, which sends pressure readings via a 4-20mA signal. When pressure in the separator reaches extremely high-pressure levels, this is considered a dangerous condition. To attain high integrity of the separator pressure SIF, the diagnostics of the logic solver shall be monitored continuously. Should the logic solver experience any faults or separator pressure breach its high-pressure limit, a shutdown of the separator should take place.

All separator SIFs require that logic solvers be IEC 61508 certified and SIL 2 capable. Due to limited power supply and remote locations, the logic solver shall power the connected pressure transmitter and be suitable for outdoor installation and harsh environments.

Separator Pressure SIF Requirements

- Logic solvers used for each separator SIF must be IEC 61508 certified and SIL 2 capable.

- The logic solver must be able to provide power to the pressure transmitter on the separator.

- Outdoor installation location requires an ambient operating temperature range of -40 to 85°C.

- A High-Pressure alarm needs to be configured for shutdown initiation.

- Logic solver internal diagnostics/faults must be continuously monitored.

- Logic solver shall shutdown separator operation in the event of high pressure or logic solver fault.

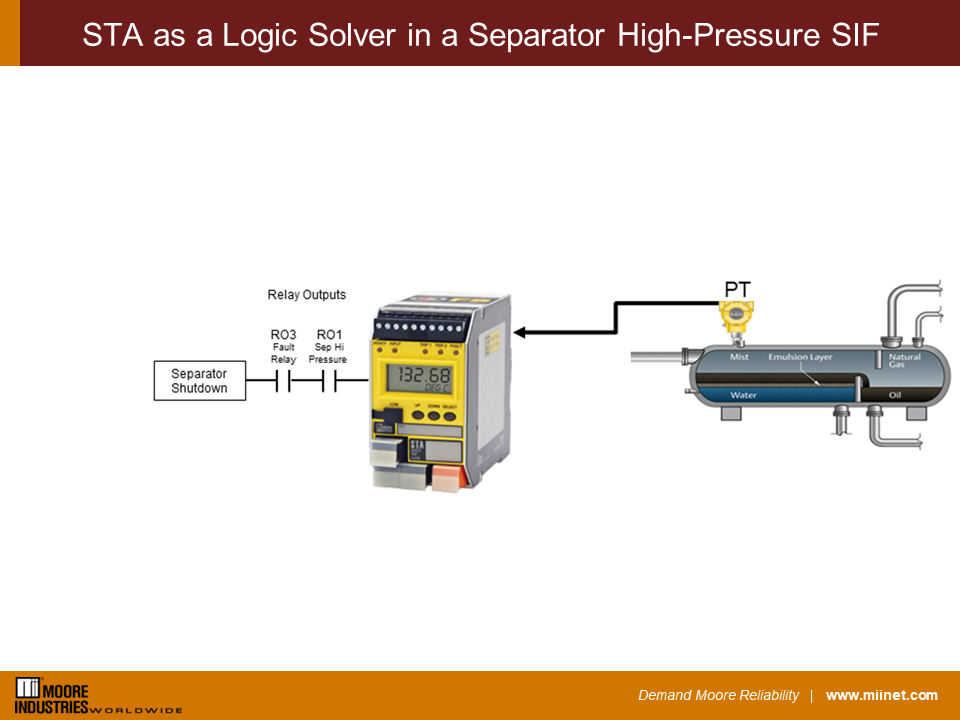

The STA Safety Trip Alarm is a single-loop logic solver that responds to potentially hazardous process conditions by providing emergency shutdown or early warning indication in an SIS. It is certified by exida® and is SIL 2/3 capable. The STA is pushbutton or PC-configured and has a local readout to show separator pressure. An auxiliary 24V power supply is available on the input terminals to provide power to the separator’s pressure transmitter.

The STA provides two process alarms and one fault relay output. Each alarm is tied to a failsafe SPDT relay output. The STA has a fault relay that is triggered if the internal diagnostics uncover any hardware or firmware faults. If any faults are detected, the fault relay will be engaged. As the figure above illustrates, the hi-pressure alarm relay output and the STA fault relay are physically wired in series with the shutdown circuit or final actuator. Since the STA process relays and fault relay are failsafe (de-energize to trip), the separator shutdown circuit will be initiated if there is a hi-pressure alarm, STA fault, or power loss to the STA.

Since the STA is a single-loop logic solver and only accepts one input, three STAs will need to be installed to handle each of the three separator SIFs. If the SIF needs to meet SIL 3, two STAs could be used as the logic solver element for each SIF in a 1oo2 voting scheme. This would require the process relays and fault relays of each STA to be wired in series to initiate the shutdown circuit. In addition, the sensors and final actuators should be assessed for their SIL 3 capabilities.

Key attributes of the STA:

- Exida approved for use in a Safety Instrumented Systems

- The SIL 2/3 Capable STAs are much simpler to program than safety PLCs and cost significantly less

- Suitable for extreme environments

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or use our online form.