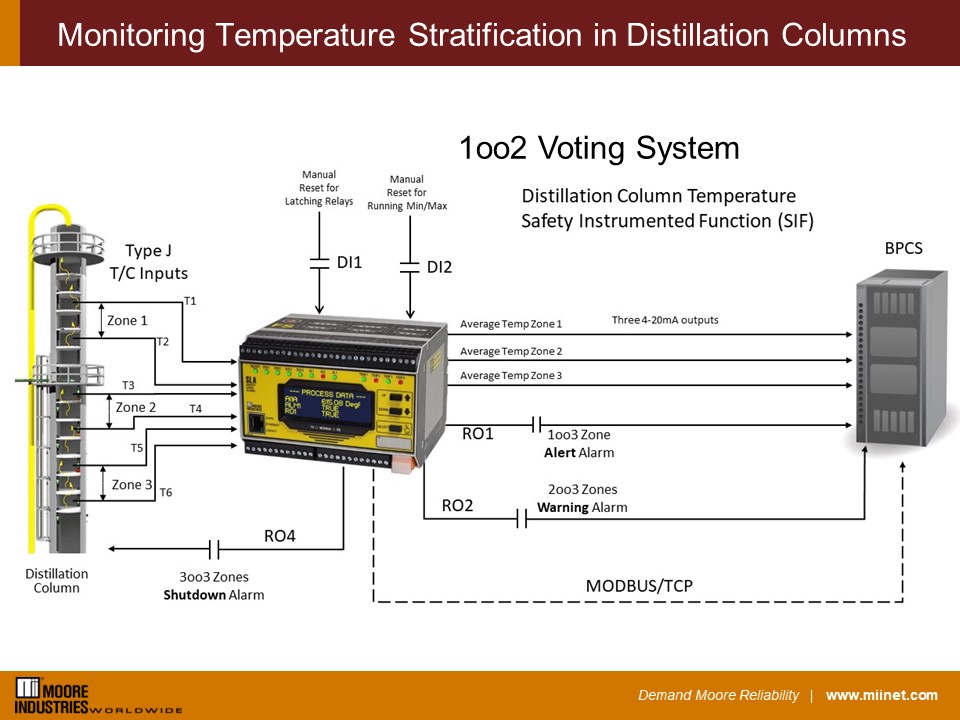

Temperature stratification is normal in distillation columns. However, in some chemical or refinery processes, too much temperature differential between layers within the column can yield poor quality product or create a dangerous condition that could lead to a column rupture or explosion. In this application, Zone 3’s ideal temperature range is around 250 degC, Zone 2’s ideal temperature range is around 200 degC, and Zone 1’s ideal temperature range is around 150 degC. Closely monitoring these temperatures, providing alarming, and possible shutdown of the process is crucial.

The SLA can help mitigate this situation by accepting up to six temperature inputs, in this case type J thermocouples, and performing an absolute differential calculation between two closely mounted temperature elements in each zone. The SLA can implement up to 16 alarms based on any input, equation, or combination of inputs/equations.

This application requires three separate alarms, one for each zone, where each alarm is configured to activate if more than a 25 degC temperature differential exists between each zone’s lower and upper temperature points. The temperature differential for each zone is calculated with an absolute differential equation via the SLA’s Internal Variable/Equation Editor feature. Three of the SLA relay outputs will be driven by an alarm voting strategy. Relay Output 1 will activate an alert if any of the three zones experience an alarm (1oo3 voting). Relay Output 2 will issue a warning if any two of the zones are in alarm (2oo3 voting), and Relay Output 4 will initiate a shutdown of the distillation column if all three zone alarms are active (3oo3 voting) or if there is an SLA device fault.

A contact closure wired to the SLA’s Discrete Input 1 is used to release Relay Outputs 1, 2 & 4, all latching relays, once an alarm voting condition(s) has become inactive. Discrete Input 2 will be utilized to reset a running min/max function that will capture each zone’s maximum temperature, since last reset.

A BPCS (Basic Process Control System) monitors each zone’s average temperature via the SLA’s three analog outputs. All inputs, outputs, alarms, faults, and various other parameters from the SLA are transmitted via MODBUS/TCP over Ethernet to the BPCS. Additionally, the SLA’s event logger will be enabled and configured to monitor and store all diagnostic and alert information for the analog inputs and relay outputs. This event log file can then be downloaded from the SLA as a .csv file for viewing, analysis, and archiving.

Key attributes of the SLA:

- Simple to configure 2oo3 voting alarm with check boxes and pull-down menus

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- HART pass-through of pressure transmitter diagnostics to RTU/PLC

- SLA provides 24Vdc power to all three pressure transmitters for ease of wiring

- -40 to 85 degrees Celsius ambient temperature operating range

- Standard MODBUS RTU protocol sends all process and diagnostic data to RTU/PLC

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or use our online form.