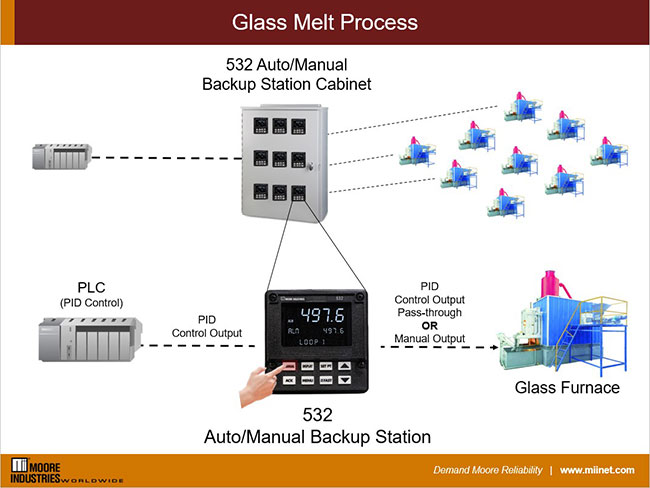

When a glass recycling division was upgrading one of their recycling facilities from sorting glass 10mm in size (or larger) down to 3mm in size, which provided more business opportunity and diverted more glass from landfills, they looked to Moore Industries 532 Auto/Manual Backup Stations to provide manual backup of their critical Melt Furnace PID control loops. Three panels were fitted with twenty-five 532 Auto/Manual Backup Stations to monitor the host PLC’s PID control for each Melt Furnace chamber. Maintaining temperature control for the Melt Furnaces is paramount and should the primary host controller fail, solidified glass could severely damage and perhaps ruin the furnace. These 532 Auto/Manual Backup Stations were chosen because they can sit passively on the PID control signal from the PLC and if that signal should fail, the 532 automatically generates a control signal based on the last known host PLC value allowing for seamless manual takeover. In addition, during normal operation the 532 allows local operators to quickly switch between Host and Manual control modes when and if required. This provided the recycling facility with the critical redundancy and optional local control that they needed for their Melt Furnaces.

The plant engineers’ control strategy utilized the following strategy:

- Under normal circumstances, the 532 Auto/Manual Backup Station was left in AUTO mode and allows the 4‐20mA control signal from the PLC to pass straight thru unimpeded to the Melt Furnace’s heating system.

- If the PLC should fail, the 532 Auto/Manual Backup Station automatically detects this and enters MANUAL mode and maintains the last known output value. This then allows plant operators to manually control the output signal going to the Melt Furnace heating system until the PLC is repaired.

- Upon failure of the host PLC system, the 532 Auto/Manual Backup Station provides an alarm contact to a local klaxon that alerts plant personnel that they have lost primary host control.

- If at any time during normal operation the plant operators needed to take manual control, the MANUAL mode button on the 532 allowed them to do so.

Moore Industries 532 Auto/Manual Backup Station ensures the integrity of your processes with maximum reliability. Isolated inputs and outputs guard against electrical interference, the front face meets NEMA 4X standards for watertight operation, and solid metal housing and sturdy rubber keys enhance durability. The 532 has three bright, crisp vacuum fluorescent digital display areas, with two offering up to nine characters of true alphanumerics. Additional operator-friendly features include custom programmable alarm messages, keys that illuminate when in use and an easy-to-use menu system.

Key Attributes

- Provides manual backup of critical control loops.

- Transfers between REMOTE and LOCAL modes via keypad command, digital input, RS-485 communications or loss/return of control signal.

- Upon keypad command or loss of signal, generates a control signal based on the last known HOST value or preprogrammed value and provides alarm output of signal loss.