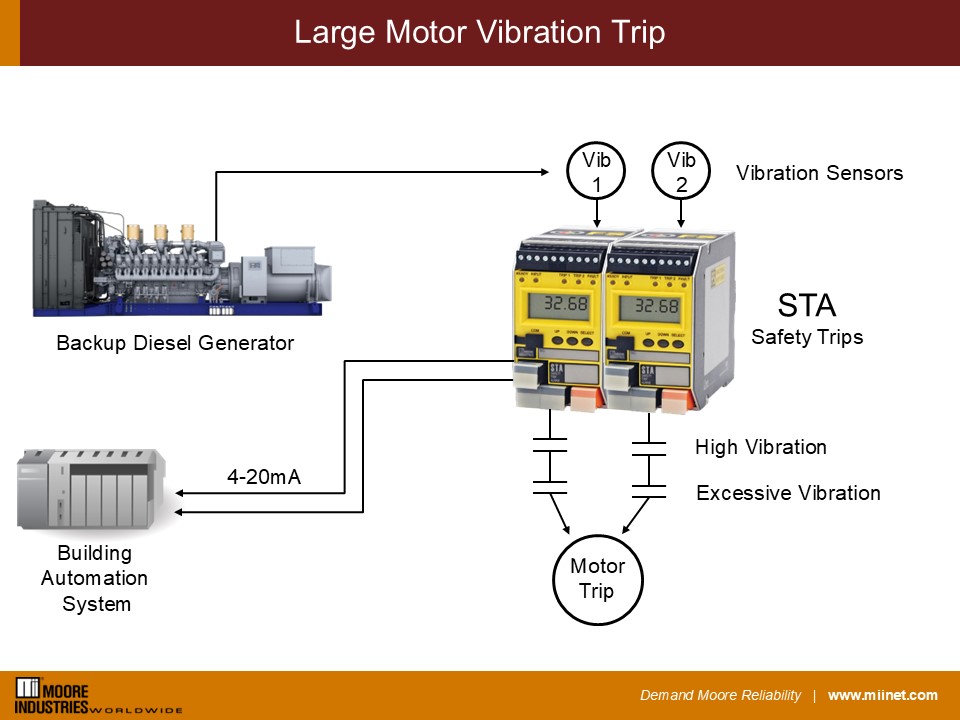

Large diesel generators are often used to provide backup power in data centers. However, these powerful motors can create excessive vibration, an early indicator of mechanical issues that may lead to damage, costly repairs, or unplanned downtime. In some cases, unchecked vibration can even pose safety risks.

To mitigate these risks, vibration sensors or accelerometers can be installed to detect abnormal vibration levels. Alarm trips then monitor these sensors, triggering a local trip signal to the motor when thresholds are exceeded. If required, the vibration data can also be retransmitted back to the control system via the alarm trip’s analog outputs.

The diagram above illustrates the STA Functional Safety Limit Alarm Trip logic solver, which is IEC 61508 certified. For applications that are not part of a Safety Instrumented System (SIS), a standard alarm trip is sufficient, making the SPA2 Programmable Limit Alarm Trip an excellent alternative.

Key Attributes:

- Capable of monitoring and powering vibration sensors

- Field or PC-Programmable

- Auxiliary analog output available for building management system

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

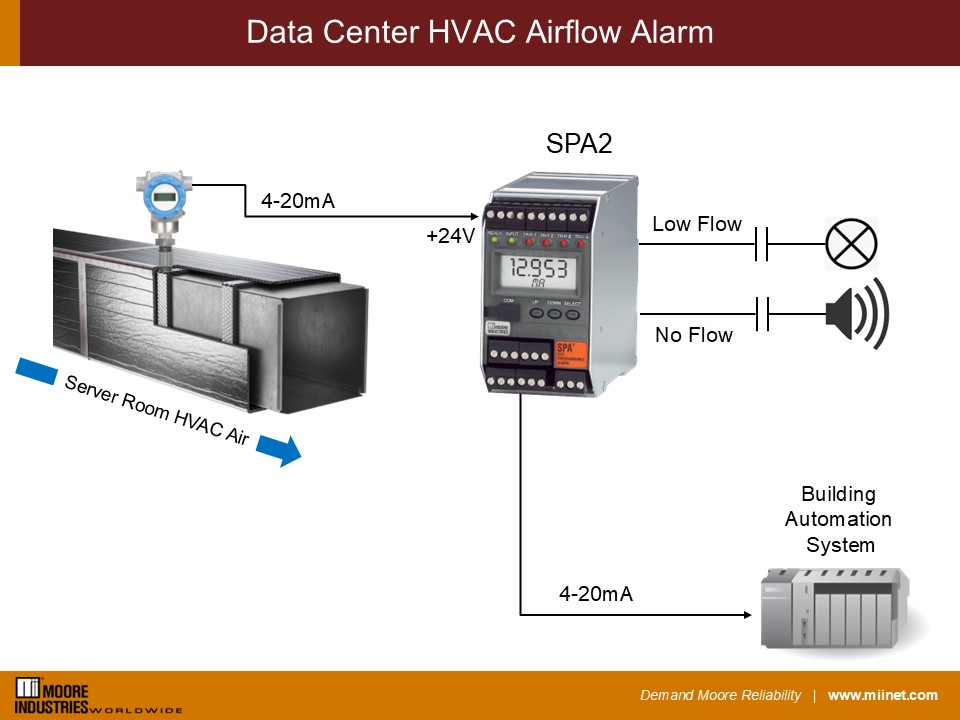

Maintaining sufficient airflow through data center HVAC plenums is critical to keeping server rooms at optimal operating temperatures. Although HVAC control systems continuously monitor and regulate airflow, additional layers of redundancy are often implemented to ensure uninterrupted cooling.

To safeguard against low-flow conditions, the SPA2 Current Alarm Trip provides reliable protection by monitoring and alarming when airflow drops below the required rate. The SPA2 comes standard with up to four SPDT alarm outputs, along with a TX option (24VDC @ 25mA) that powers the loop-powered airflow sensor, eliminating the need for a separate auxiliary 24VDC power supply. An optional 4-20mA output can be utilized to transmit real time flow rates to the building automation system.

For maximum flexibility, the SPA2 can be configured in the field using either front-panel push buttons or free PC-based software. Each alarm function supports high or low trip settings, as well as Failsafe or Non-Failsafe relay operation. Advanced features such as adjustable deadband, time delay, and latching/non-latching options allow the SPA2 to be tailored to meet virtually any process application requirement.

Key Attributes:

- Powers and Receives 4-20mA Signal from Airflow Sensor

- Relays rated 5A, 250VAC

- Field programmable with display

- Adjustable deadband and optional analog output for air flow monitoring

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

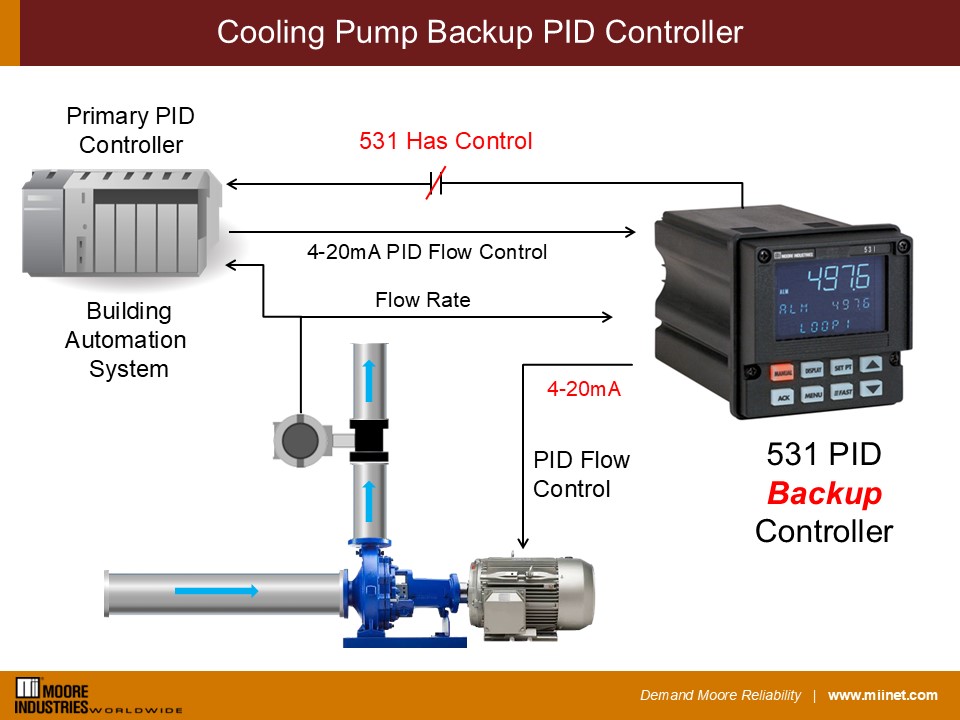

Data centers circulate massive amounts of cooling water to maintain server rooms at optimal operating temperatures. While the Building Automation System (BAS) typically manages the primary pumps, a redundant safeguard is often essential to ensure uninterrupted water circulation in the event of a control system failure.

For these and other mission-critical applications, the ¼ DIN 531 Hot PID Backup Station provides a reliable secondary layer of protection. Specifically designed to serve as the backup master on critical loops, the 531 continuously monitors the 4–20mA signal passing through to the final control element during normal operation. Should the primary PID pump controller fail, the 531 immediately assumes PID control, ensuring continuous pump operation. At the same time, it transmits a notification to the primary controller or other watchdog systems, alerting facility operations that the backup has engaged.

The 531 is equipped with a bright vacuum fluorescent display, featuring a large five-digit upper readout along with two nine-character alphanumeric lines for clear, at-a-glance status updates.

Key Attributes:

- Easy to configure

- HOT PID Backup station

- Large display with local indication of PV and CV-Nema 4X case with UL Approval

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

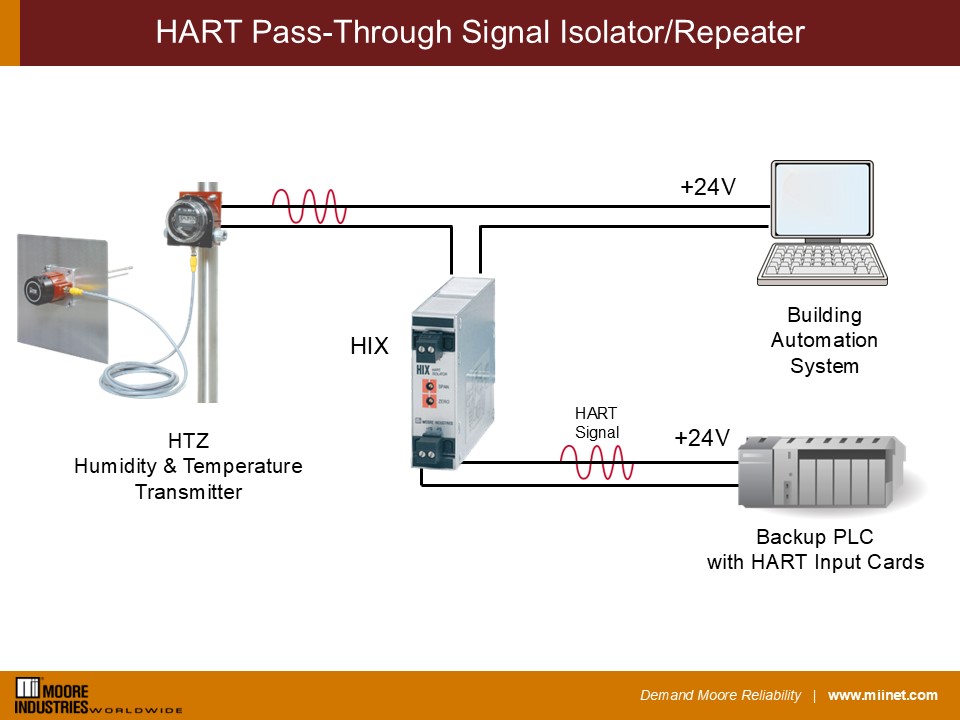

Large data centers rely on continuous monitoring of critical environmental variables such as temperature and humidity. Failure to monitor these closely can result in costly downtime and equipment damage. When humidity is too low, the risk of electrostatic discharge (ESD) increases, potentially harming sensitive electronics. When too high, condensation may occur, leading to corrosion or short circuits within servers.

Because these critical signals often need to be shared with multiple control devices, wiring them in series is risky since if one receiving device fails, the entire loop becomes open and inoperative.

For applications like these, consider the HIX HART Signal Isolator. Built for reliability and rugged performance, the HIX is a two-wire, loop-powered isolator with full HART pass-through capability. It enables you to share essential process variables, along with valuable HART data, with both your primary control system and your backup controller. This ensures system integrity, providing added protection and safety by preventing disruptions to the primary loop when work is performed on the secondary backup loop, and vice versa.

Key Attributes:

- HIX provides area isolation and follows failed inputs down below 3mA

- Class I Div 2/Zone 2 approvals

- HART pass-through allows critical signals to be shared with backup system

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

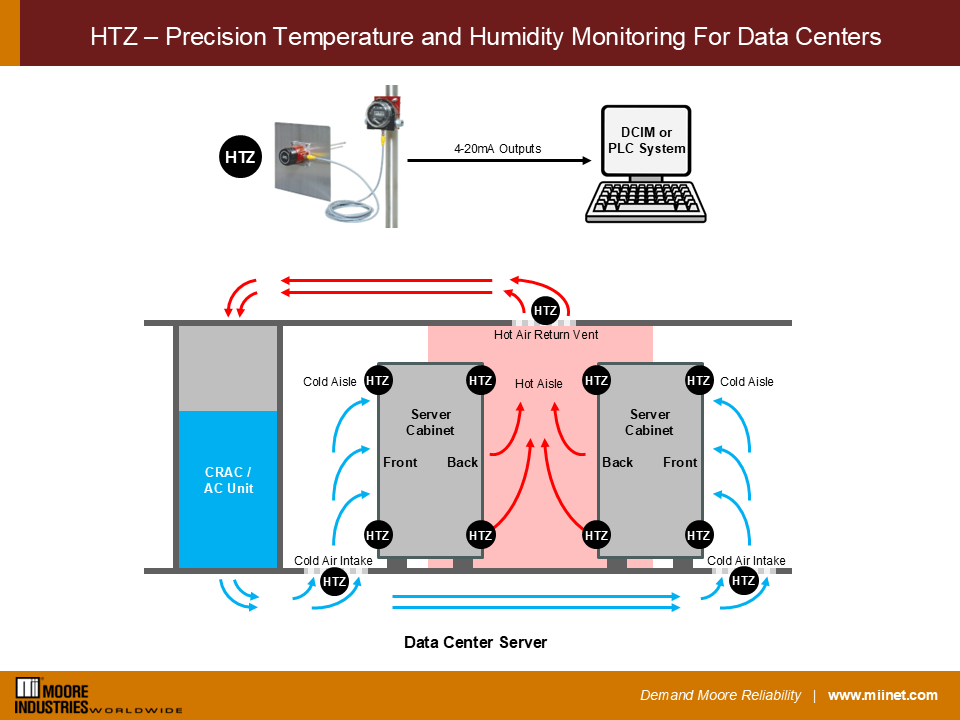

With data center servers operating around the clock and no margin for equipment failure, reliable, accurate, and repeatable humidity and temperature monitoring is essential.

![]()

The HTZ Humidity and Temperature Transmitter offers flexible installation options with either a duct-mounted sensor assembly or a flexible probe, making it ideal for monitoring in ducts and other hard-to-reach locations. For broader applications, the sensor can also be wall-mounted to measure ambient room conditions.

The HART-programmable HTZ includes a remote display and two configurable analog outputs, which can be programmed to transmit humidity, temperature, or dew point, providing the versatility needed for critical environmental monitoring.

Key Attributes:

- Verastile duct mount/wall mount or a flexible designed humidity sensor

- +/- .75% humidity measurement

- HART programmable with two outputs and local display

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

In high-performance data centers, environmental control is critical to ensuring uptime, efficiency, and the longevity of sensitive equipment. Among the most important variables to regulate is relative humidity, which should remain within the optimal range of 40% to 60%.

With servers operating around the clock and no margin for failure, reliable humidity transmitters deliver the real-time environmental data needed to protect IT infrastructure.

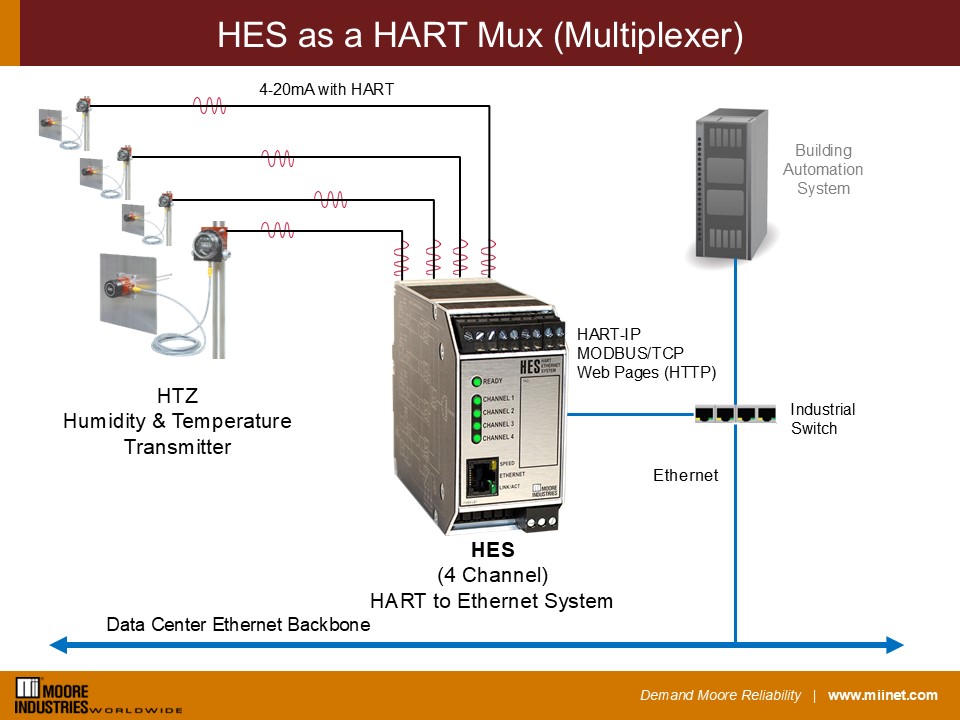

To simplify wiring while enabling advanced diagnostics through the HART protocol, the HES HART-to-Ethernet Gateway System can be deployed in clusters or remote locations and connected directly to the facility’s Ethernet backbone. Data collected from the HTZ Humidity and Temperature Transmitter is then transmitted via MODBUS/TCP to the Building Automation System, providing seamless monitoring and control.

Key Attributes:

HES can poll for:

- Dynamic Variables (PV, SV, TV, and QV)

- Up to 128 Device Variables from HART 7 devices

- 25 Bytes of diagnostic data (Command 48) in addition to the above variables

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

A major data center project has placed high priority on environmental control to maintain server reliability and operational efficiency. The facility is designed to house rows of high-density computer servers that operate continuously, 24/7. To mitigate risk and protect sensitive equipment, precise monitoring of temperature and relative humidity is essential, particularly in critical airflow zones within the server room. Maintaining a stable relative humidity between 40% and 60% is key to ensuring optimal conditions. Humidity that falls below this range can increase the likelihood of electrostatic discharge (ESD), a dangerous threat to electronic equipment. On the other hand, exceeding this range increases the risk of condensation build-up, which can cause electrical shorts or hardware corrosion.

When precision and dependable environmental monitoring is critical, the HTZ sets the standard. The HTZ is a rugged, industrial-grade transmitter designed for demanding environments.

Key Attributes:

- Accurate, stable measurements of relative humidity and temperature

- Two Configurable outputs (4-20mA with HART)

- Long-term reliability with minimal maintenance

- Compact design for easy integration in tight rack or duct locations

- HART or PC-Programmable for quick deployment and management

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.

We are thrilled to announce a significant feature update for the HES HART to Ethernet Gateway System, introducing HART Tunneling which enables remote communication with HART field devices. This new feature allows seamless bi-directional HART data transmission between PC-based HART software applications and HES connected field devices over Ethernet.

We are thrilled to announce a significant feature update for the HES HART to Ethernet Gateway System, introducing HART Tunneling which enables remote communication with HART field devices. This new feature allows seamless bi-directional HART data transmission between PC-based HART software applications and HES connected field devices over Ethernet.

HART Tunneling with the HES permits users to send read and write HART commands remotely with any HART-capable software application, such as PACTware or an asset management system, through the HES without requiring physical access to field instruments. Acting as a gateway, the HES facilitates seamless HART communication between Ethernet and twisted pair networks, simplifying the configuration, monitoring, and diagnostics of remote HART devices.

Unlike costly and complex HART multiplexer systems, the HES now offers a simple and cost-effective approach for connecting to just one or a few critical remote HART devices over your facility’s local or remote Ethernet infrastructure.

Key features of HES HART Tunneling:

- Seamless Integration – Direct communication from PC-based HART software applications to field devices over Ethernet networks.

- Enhanced Accessibility – Remote configuration and diagnostics monitoring of HART field devices from a control room or off-site location.

- Security Measures – A security jumper on the HES enables or disables HART tunneling to address cybersecurity concerns.

- No Additional Cost – All new HES units include the HART Tunneling feature at no extra charge. The firmware on previously supplied HES units can be upgraded to include the HART Tunneling feature.

To use HART Tunneling with the HES, a Virtual Serial Port (VSP) software application is required. The VSP creates the bridge between your HART PC-based software and the HES, enabling remote access without physical connection to the field.

Learn Moore about the HES HART to Ethernet Gateway

In industrial facilities, engineers and technicians are often tasked with configuring or troubleshooting HART devices that are sometimes installed in remote or hazardous locations. Traditionally, this means walking out to the field with a handheld communicator or temporarily connecting to transmitter wiring from a control room or instrument panel location. This manual approach is not only time-consuming and inefficient, but it also increases risk and limits continuous access to valuable HART diagnostic data.

While many facilities use PC-based asset management tools or device configuration software like PACTware for advanced HART communication, bridging those tools to HART field devices typically requires complex networking or dedicated multiplexers, introducing extra hardware, integration headaches, and cost.

With HART Tunneling through the HES HART to Ethernet Gateway System, these challenges can be solved by enabling direct, remote access to HART field devices from any HART-capable application on a PC such as PACTware.

With HART tunneling, users can send read/write HART commands over Ethernet directly to a wired HART device connected to the HES. Acting as a gateway, the HES transparently transfers HART packets between Ethernet and the HART loop, eliminating the need for field visits or other specialized hardware. This allows facilities to configure, calibrate, or monitor HART instruments without leaving the control room, local plant intranet, or from anywhere in the world via a secure Ethernet connection.

To tunnel HART data through the HES, users will need to use a Virtual Serial Port (VSP) software application on their PC. The VSP creates a virtual COM port that HART applications can connect to. Users then configure the VSP to point to the IP address of the HES.

Once set up, any HART packets sent by the HART host software application are transmitted via Ethernet to Channel 1 of the HES (for four-channel HES models, tunneling is supported on Channel 1 only). From there, the HART field device(s) receives the command and responds, with the data transmitted back through the HES to the HART PC application in real-time.

Key Benefits of the HES with HART Tunneling:

- Remote Configuration: Easily configure, calibrate, or monitor HART devices from a PC without required trips to the field

- Software Compatibility: Compatible with HART-capable PC software applications like PACTware or other asset managers

- Reduced Downtime: Rapidly troubleshoot or update HART devices without disrupting operations

- Cost-Effective Alternative: Using HART Tunneling with the HES means no need for expensive HART multiplexers

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.