The quality and effectiveness of pharmaceutical products is critical to the industry and its users. To ensure the quality stays intact, nitrogen is often used for packaging purposes and other processes inside the manufacturing facilities. Because nitrogen is an inert gas, it is often used to exclude or push oxygen out of certain areas, including packages and containers.

Pharmaceutical companies use a method called nitrogen blanketing to protect processes that are used to make their products. Nitrogen blanketing strategies are implemented during production, storage, transportation, and final packaging. Nitrogen blanketing involves adding nitrogen liquid or gas to fill the area between the fill line of a process storage vessel’s content and the top of that vessel. The nitrogen displaces the oxygen inside, which helps ensure that oxygen and moisture don’t contaminate the product or cause a potentially explosive situation due to excess oxygen.

The level of oxygen inside of the Manufacturing Facilities where nitrogen is used must be monitored because the same nitrogen used for oxygen displacement to preserve the valuable contents of the vessel could become deadly to the employees working in the room. Nitrogen leaks can cause the air in the room to become oxygen-deficient, which could cause the employees to suffocate.

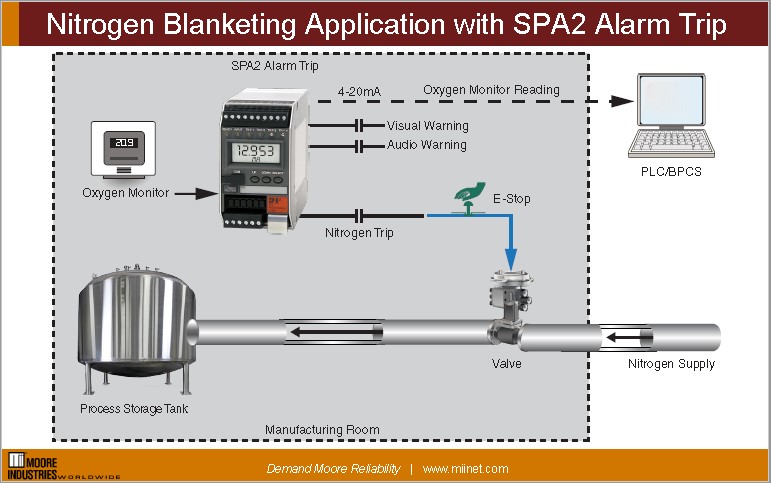

In the above application, an Oxygen Monitor is utilized in conjunction with a Moore Industries SPA2 Programmable Limit Alarm Trip to help avoid this potentially dangerous situation. The Oxygen Monitor provides the oxygen level input to the SPA2 from the inside of the room where the process is occurring. The SPA2 provides two or four independent and individually configurable alarm relay outputs, one of which can be designated to shut off the flow of nitrogen supply when the Oxygen Monitor detects low oxygen in the room; which could be caused by a nitrogen leak in the Process Storage Tank. An E-stop can also be wired in series so that operators can shut off the nitrogen supply manually. The other SPA2 relays can be used to alert employees by being wired to audible and visual warnings. An optional AO analog output on the SPA2 can communicate the Oxygen Monitor readings to a PLC, BPCS or auxiliary safety system.

Key Attributes

- Programmable input/output parameters and “Universal” DC or AC power input.

- Two or four independent and individually configurable alarm relay outputs.

- Optional AO analog output, any range between 0-20mA and 0-10V