The Problem

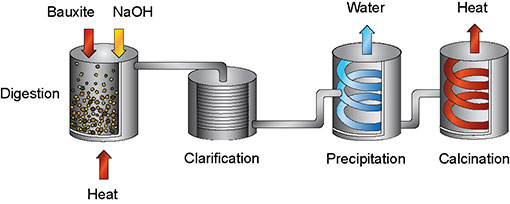

The process of converting bauxite to alumina for aluminum metal refining involves a complex manufacturing process. Much of this process requires critical temperature and pressure control, which if left unchecked could result in catastrophic consequences, such as damaging equipment, polluting the environment and even severely injuring employees. Consequently, a Safety Instrumented System (SIS) is often required for the final filtering step before the liquor slurry is sent to the precipitators. These final stage filters consist of a series of “leaves” that remove the impurities and remaining solids in the liquor. The SIS for these filters needs to be cost-effective, easy to commission and should be approved to the latest IEC 61508 safety standards.

The Solution

Most alumina refineries have multiple filters that need to be monitored for production efficiency and damage. On each of the 20 filters, safety rated pressure transmitters are used in conjunction with the STA – Safety Trip Alarm. The STA acts as the safety logic solver, used to close the final control element - a spring loaded failsafe valve. This provides the required level of safety protection while allowing each filter to be easily taken offline or serviced without affecting the other operating filters. The STA was chosen over a safety PLC for its simplicity, exida approvals, local indication, lower cost and ease of configuration and maintenance.

Most alumina refineries have multiple filters that need to be monitored for production efficiency and damage. On each of the 20 filters, safety rated pressure transmitters are used in conjunction with the STA – Safety Trip Alarm. The STA acts as the safety logic solver, used to close the final control element - a spring loaded failsafe valve. This provides the required level of safety protection while allowing each filter to be easily taken offline or serviced without affecting the other operating filters. The STA was chosen over a safety PLC for its simplicity, exida approvals, local indication, lower cost and ease of configuration and maintenance.

Do you want more information? Download the STA datasheet or the overview of the FS Functional Safety Series. Or visit the catalog.

Need to get price or availability or have a technical question? Send us a message using E-Help.