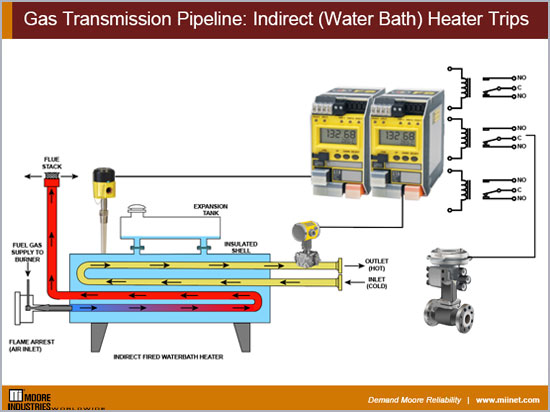

Natural gas is transported at high pressure, however, it is distributed to industrial users at a lower pressure. Pressure reduction stations are used at these distribution junctions to reduce the gas pressure using a throttling valve. However, a large reduction in pressure will cause a significant drop in the temperature of the gas of approximately 5°C for each 1000kPa reduction in pressure, known as the Joule-Thompson effect. The natural gas must be heated using an indirect Water Bath Heater (WBH) before the pressure is reduced in order to avoid the formation of ice crystals and hydrates which can cause major damage to equipment. If preheating is not applied within the process, equipment may also experience embrittlement of piping and fittings, and blockage of filters and regulator/valve seats.

Water bath heaters burn a fuel such as fuel gas or fuel oil within the horizontal “U”-shaped firebox immersed in the lower portion of the water bath. The heat released by the burning fuel is quickly transmitted through the fire tube wall to the water bath, maintaining it at the desired temperature. The fluid to be heated (natural gas, oil, process fluids) flow through the process coil of the heater which is immersed in the upper portion of the water bath. Heat is transmitted from the hot water bath through the tube-wall to the fluid inside the process coil.

The heater temperature controller maintains the water bath temperature at the desired level by controlling the firebox fuel gas supply. A temperature of 87 ˚C is considered the maximum temperature for operation. It is best to operate the heaters at less than 87 ˚C when inlet condition and/or outlet temperature requirements allow. Operating the bath temperature at the minimum temperature required to give hydrate protection in either the pipeline or separator not only saves fuel, but provides maximum liquid recovery in the downstream equipment.

Water bath heaters may also be used for heating transfer fluids; regeneration gas heating, vaporizing and superheating LPG and LNG; and heating sensitive gases and fluids, such as crude oil, helping to reduce its viscosity and enhance separation efficiency in upstream process units.

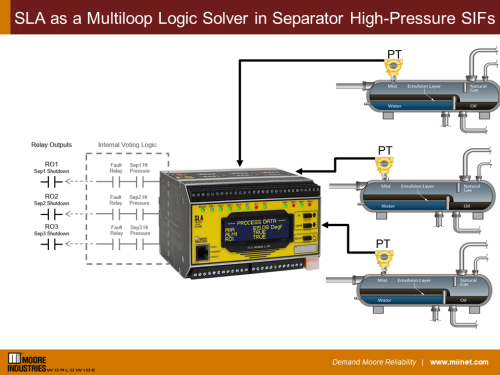

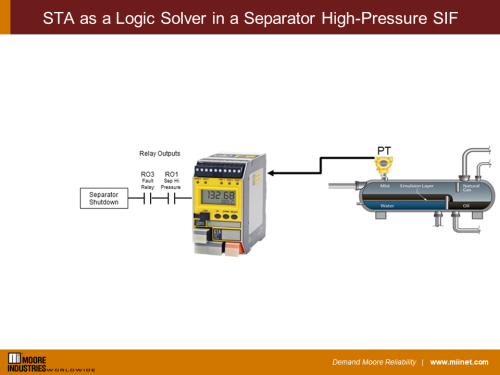

The safety of these heaters is paramount, given the environment in which they operate. IEC61508 certified SIL2/3 capable Alarm Trips such as the Moore Industries STA Safety Trip Alarm are commonly employed in the protection systems of indirect Water Bath Heaters for high temperature trips on Flue stack, Low Pressure Switch for Fuel gas, and can be used to alarm on overpressure heater tank, burner failure, changes in fuel pressure, low water level, and low heat output.

The STA Safety Trip Alarm is exida certified up to SIL 2/3 capable, can detect abnormal operating conditions (Hi Temperature – Hi & Lo Pressure) and provide Fail Safe relay outputs to independently manage the safe operation of the water bath heater.

Key attributes:

- Class I Div 2/Zone 2 approval and local display

- Third-party exida certified SIL2/3 capable

- Multiple trip voting available if needed

View the STA in the online catalog.