A processing line was in the middle of an upgrade and ran into a major problem: they needed to transmit twice as many pneumatic signals as they had before. This was especially challenging because the control panel had very limited space but now needed to house 32 Current-to-Pressure (I/P) transmitters and 16 Pressure-to-Current (P/I) transmitters.

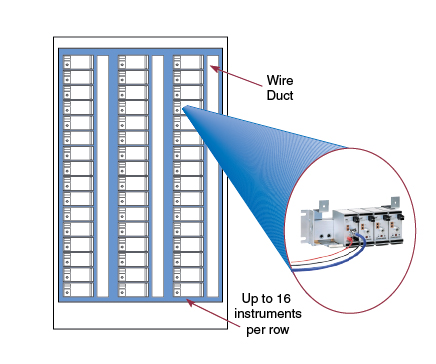

Moore Industries was able to solve this problem with an installation of our IPT2 Current-to-Pressure Transmitters and PIT Pressure-to-Current Transmitters. Both pneumatic transducers are slim – the IPT2 is 39mm (1.55 in) and the PIT is 25mm (1.00 in) – meaning they can provide outstanding performance in limited space. Up to eight IPT2s or 12 PITs fit on one foot of DIN rail. This allowed all 48 units to easily fit in an enclosure of 36”x36”x8”

In addition to the small footprint the IPT2 units were installed into cost-effective multi-unit SIR racks (as seen above) that come in 5, 10 or 15 positions. These racks eliminate the wasted time and unnecessary cost of using individual pneumatic piping, mounting blocks, pressure gauges and filters for each I/P unit. Only one air supply pipe is needed to efficiently handle an entire rack of units. These racks feature self-sealing pneumatic connections that let you put units in and out of service without air loss.

Do you want more information? See the products in the onlie catalog, and download their data sheets:

- IPT2 Current-to-Pressure Transmitters

- PIT Pressure-to-Current Transmitters

- SIR 5-, 10-, 15-Position Surface-Mounted IPT-DIN Rack

Need to get price or availability or have a technical question? Send us a message using E-Help.