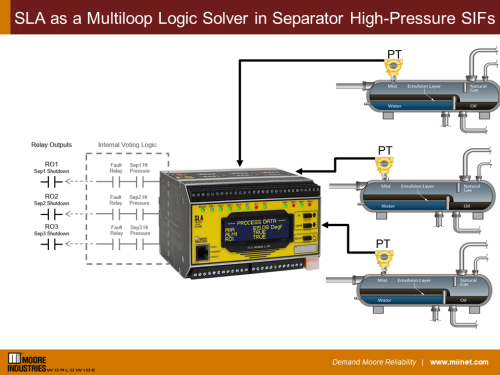

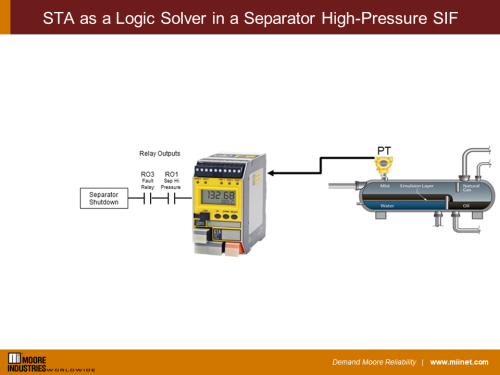

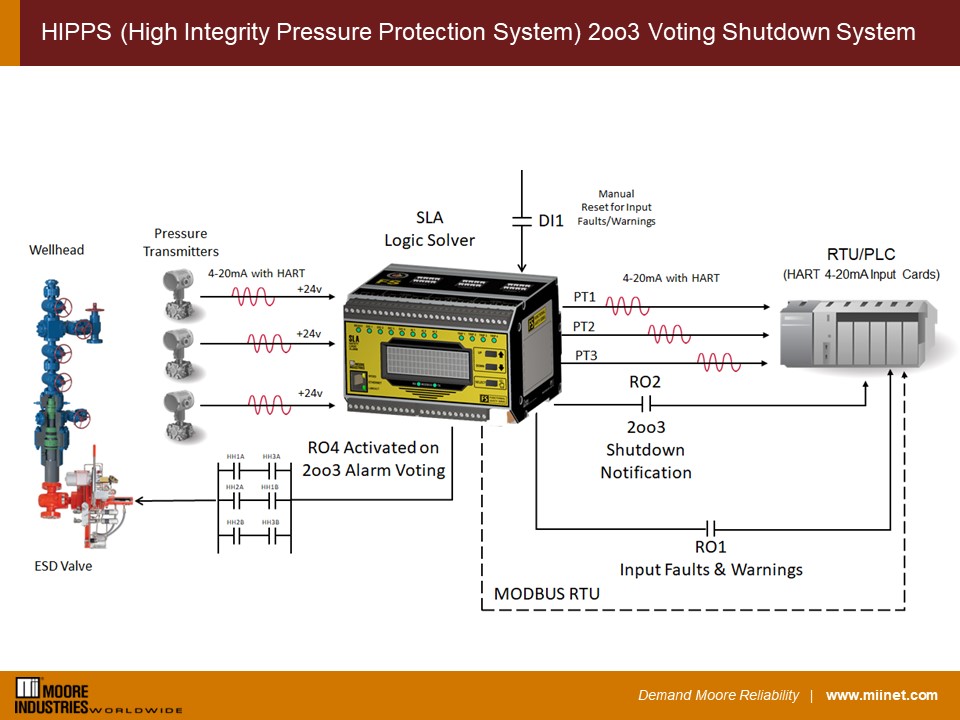

Upstream gas wellheads can experience extremely high pressure and surges. In order to protect personnel and equipment, wellhead casing pressure is often monitored in case there is a situation where the wellhead needs to be shutdown. Traditionally simple pressure switches were used but today companies are required to implement proper safety systems. Figure 13.1 shows the SLA installed in a remote oil and gas wellhead application using 2oo3 voting logic to ensure pressure protection.

In this application, to protect personnel and the process from high pressure spikes, the three separate pressure transmitters are wired to the SLA where it can perform a 2oo3 safety voting architecture to shut down the well when dangerous conditions exist. The SLA’s built in loop power supply on each of its three channels provides operating power to all three smart HART pressure transmitters. The HART signal from the three pressure transmitters is passed-through to each of the SLA’s corresponding analog outputs so the RTU/PLC has direct access to all HART programming, variables, and diagnostics of each connected transmitter.

The retransmission of these three pressure transmitters by the SLA, versus wiring in series with the RTU/PLC input cards, provides higher availability to the safety function since a catastrophic failure in the analog input cards or the RTU/PLC itself doesn’t affect the 2oo3 logic shutdown function of the SLA.

Additional relay outputs of the SLA also keep the RTU/PLC informed of shutdown status and any input faults experienced by the SLA. A digital contact input allows any alarm or relay configured as latching to be manually reset. Finally, all inputs, outputs, internal equations, variables, alarms, relay status and more are digitally transmitted to the RTU/PLC via a read-only MODBUS RTU signal.

Key attributes:

- Simple to configure 2oo3 voting alarm with check boxes and pull-down menus

- SIL 2/3 capable exida® approved to IEC 61508:2010 standard

- HART pass-through of pressure transmitter diagnostics to RTU/PLC

- SLA provides 24Vdc power to all three pressure transmitters for ease of wiring

- -40 to 85 degrees Celsius ambient temperature operating range

- Standard MODBUS RTU protocol sends all process and diagnostic data to RTU/PLC

If you’d like to talk to sales or request a quote, call us at 1 (800) 999-2900 in the US and Canada or +1 (818) 894-7111 and select 1 for Sales, or send us an email via our online form.