Q. We have several short thermowells in our process, ranging from 2-inches to 6-inches. Our process is very stable, but we have noticed a temperature measurement shift when the outside air temperature rises or falls. We have tried calibration, but it still doesn’t correct the temperature swing we see. What would you suggest we change that will prevent these temperature swings?

Q. We have several short thermowells in our process, ranging from 2-inches to 6-inches. Our process is very stable, but we have noticed a temperature measurement shift when the outside air temperature rises or falls. We have tried calibration, but it still doesn’t correct the temperature swing we see. What would you suggest we change that will prevent these temperature swings?

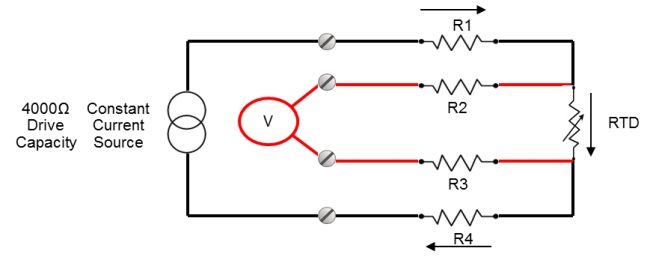

A. The most active area of a sensor can be approximated as 4 to 10 times the length of the installed element. As temperatures change outside the process, the upper portion of the sheath is exposed to these fluctuations. This part of the sheath senses a temperature difference then measures it, influencing the temperature along the full length of the sheath. We regularly see this occurrence when calibrating sensors with long sheath length exposed outside of calibration baths. The only way to measure true process temperature is to keep the sheath as short as possible.

Moore Industries manufactures the WORM, a sensor with a very short sheath length of 1.5-inches. Worm sensors are spring loaded to stay at the bottom of the thermowell. They have a faster response time and the lead wires do not measure temperature changes outside the process connection. They do not sense any outside temperature swings and only measure temperature inside the bottom area of the thermowell.

To read more about the WORM, download the data sheet.

You can also download the Get Rid of Rigid White Paper for more information on using the WORM in your process.

Do you want more information? Download the data sheet. Or visit the catalog.

Need to get price or availability or have a technical question?

Send us a message using E-Help.